Preparation method of a three-dimensional nanofiber hydrophobic sponge capable of reabsorbing oil

A technology of three-dimensional nano- and hydrophobic sponges, which is applied in fiber treatment, chemical instruments and methods, and other chemical processes. It can solve the problems of low oil absorption rate and non-reusable use of oil-absorbing sponges, achieve excellent reusable characteristics, and improve oil absorption effects. , to achieve the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

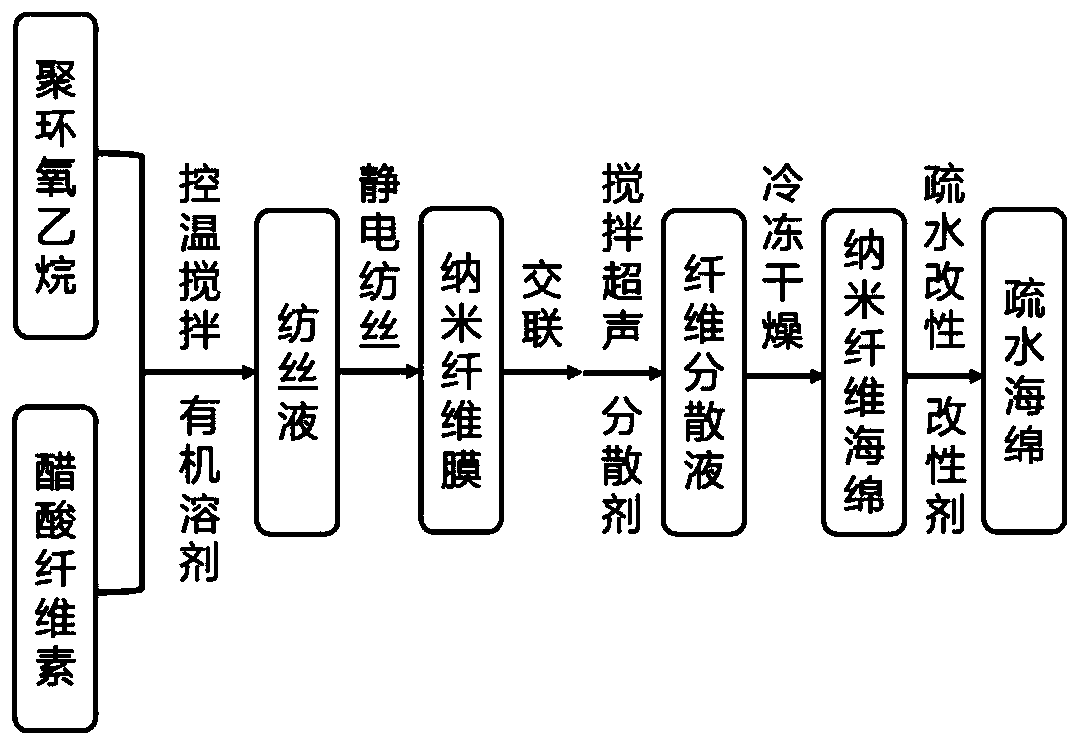

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment provides a method for preparing a three-dimensional nanofiber hydrophobic sponge, and the specific steps are as follows:

[0034] Step 1: Mix cellulose acetate and polyethylene oxide in a mass ratio of 2:1, and dissolve the mixture of cellulose acetate and polyethylene oxide in N,N-dimethylformamide, wherein the solute is The mass fraction is 10%. It was placed in a water bath at 60°C and heated at a constant temperature for 12 hours until the solute was completely dissolved, and a uniform and transparent electrospinning cellulose acetate / polyethylene oxide mixed solution was obtained.

[0035] Step II: transfer the cellulose acetate / polyethylene oxide mixed solution to the electrospinning device, adjust the process parameters of electrospinning as follows: spinning voltage 10kV, solution flow rate 1mL / h, drum receiving distance 20cm, controlled environment The temperature was 25° C. and the humidity was 30% to obtain a cellulose acetate / polyethy...

Embodiment 2

[0044] The present embodiment provides a method for preparing a three-dimensional nanofiber hydrophobic sponge, and the specific steps are as follows:

[0045] Step 1: Mix cellulose acetate and polyethylene oxide in a mass ratio of 4:1, and dissolve the mixture of cellulose acetate and polyethylene oxide in N-methylpyrrolidone, wherein the solute mass fraction is 15 %. It was placed in a 50°C water bath and heated at a constant temperature for 18 hours until the solute was completely dissolved, and a uniform and transparent electrospinning cellulose acetate / polyethylene oxide mixed solution was obtained.

[0046] Step II: Transfer the cellulose acetate / polyethylene oxide mixed solution to the electrospinning device, and control the electrospinning process parameters: spinning voltage 12kV, solution flow rate 0.5mL / h, drum receiving distance 15cm, and environmental temperature control 35°C and humidity of 45% to obtain a cellulose acetate / polyethylene oxide nanofiber membrane....

Embodiment 3

[0055] The present embodiment provides a method for preparing a three-dimensional nanofiber hydrophobic sponge, and the specific steps are as follows:

[0056] Step 1: Mix cellulose acetate and polyethylene oxide according to a mass ratio of 3:1, and dissolve the mixture of cellulose acetate and polyethylene oxide in acetone, wherein the mass fraction of the solute is 20%. And placed in a water bath at 80°C and heated for 10 hours at a constant temperature until the solute was completely dissolved, and a uniform and transparent electrospinning cellulose acetate / polyethylene oxide mixed solution was obtained.

[0057] Step II: transfer the cellulose acetate / polyethylene oxide mixed solution to the electrospinning device, and control the electrospinning process parameters: spinning voltage 16kV, solution flow rate 2mL / h, drum receiving distance 10cm, control ambient temperature 50 ℃ and humidity of 60% to obtain a cellulose acetate / polyethylene oxide nanofiber membrane.

[0058...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com