Disk-type assembled bagged catalytic distillation filler

A catalytic rectification, disc technology, applied in fractionation, distillation separation, chemical instruments and methods, etc., can solve the problems of complex processing technology, difficult to meet the requirements of catalytic rectification packing at the same time, etc., to increase the reaction flux and stitch size. Adjustable and improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In the process of synthesizing methyl acetate with dilute acetic acid under the action of NKC-9, the catalyst package is sewn with corrosion-resistant materials, the catalyst particle size is 1mm, and the stitching size between adjacent sutures of the catalyst package is 20mm. The rate of the catalytic distillation process is controlled by the surface reaction rate. The number ratio of the catalyst package to the structured packing sheet is 1:1. The component B in the catalytic rectification packing adopts window diversion packing, and the packing sheets are stacked in parallel under the catalyst package. , And curled into shape. The tower diameter is DN1000, no need to rotate when installing the upper and lower packing trays. The reaction section is equipped with 8 trays of packing. Compared with the use of ordinary strapping type catalytic distillation packing, the use of the catalytic rectification packing of the present invention has uniform radial distribution, red...

Embodiment 2

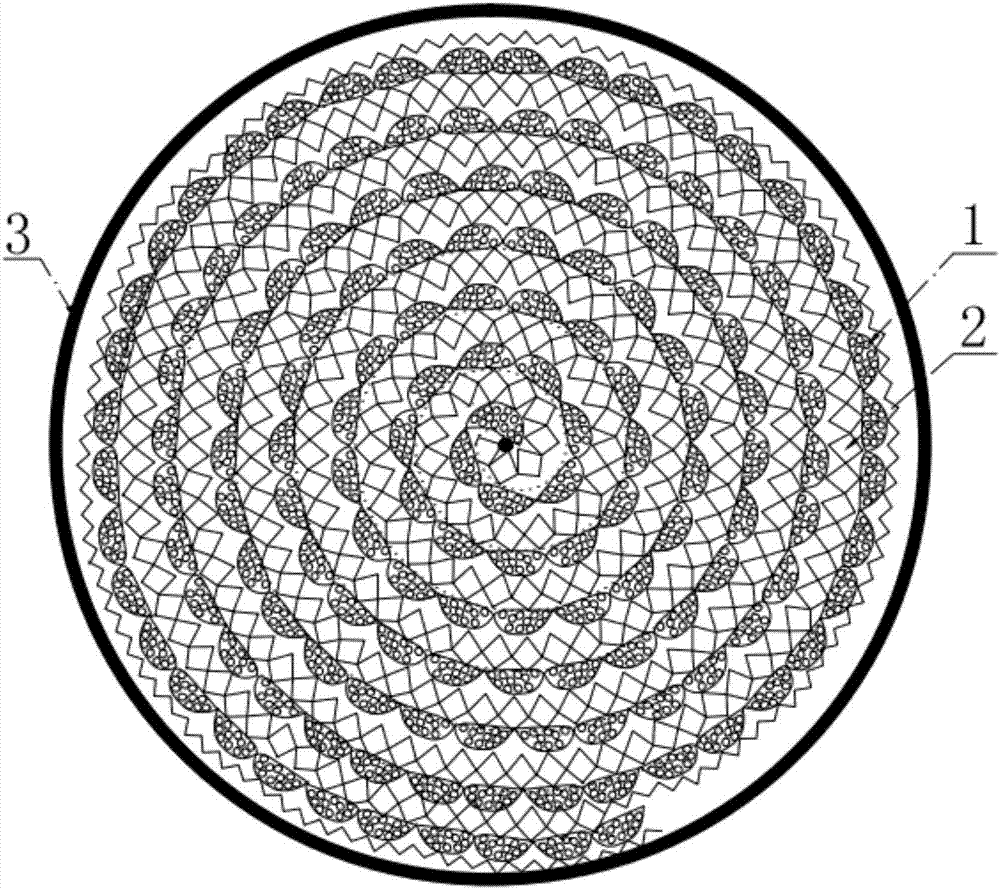

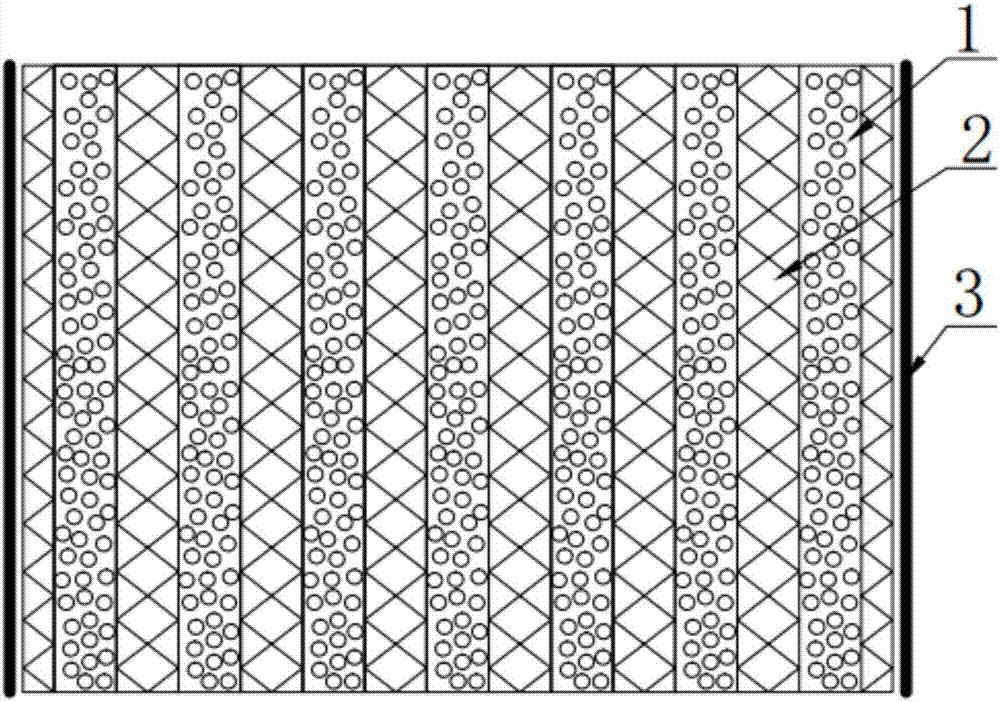

[0034] In the chlorosilane disproportionation reaction rectification device, the catalyst package is sewn with nylon cloth, the catalyst is the anti-disproportionation catalyst SA66, and the stitching size between adjacent sutures of the catalyst package is 50mm. This catalytic rectification process requires a high degree of coupling between the reaction process and the rectification process. In order to increase the liquid holding capacity of each disk packing, the ratio of the catalyst package to the structured packing is 1:2, and the component B in the catalytic rectification packing is adopted The window diversion packing, the packing sheet is evenly distributed on the upper and lower layers of the catalyst pack, stacked parallel to the catalyst pack and rolled into shape, as attached figure 1 with 2 Shown. The tower diameter is DN1200, the upper and lower packing trays do not need to be rotated when installing, the reaction section is equipped with 10 trays of packing, the ...

Embodiment 3

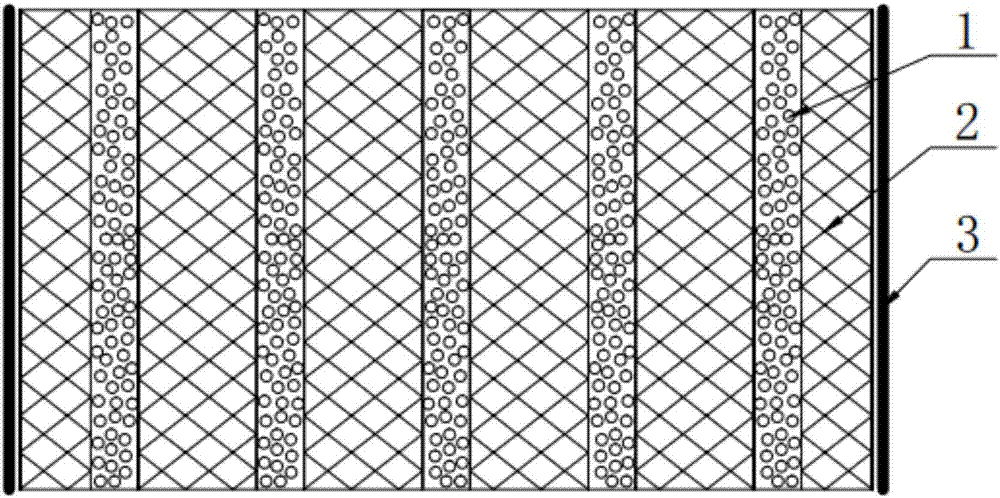

[0036] In the MTBE (Methyl Tertiary Butyl Ether) device, the catalyst package is sewn by nylon cloth, the catalyst particle size is 0.5mm, and the stitching size between adjacent sutures of the catalyst package is 15mm. This catalytic distillation process is controlled by the reaction rate and the mass transfer rate between the gas and liquid phases. The number ratio of the catalyst package and the structured packing is 1:5. The component B in the catalytic distillation packing adopts the window diversion packing. The number of the lower layer of the catalyst package is one more than the number of the upper layer. image 3 Shown. The diameter of the tower is DN800, and the upper and lower packing trays rotate 90° when installed. The reaction section is equipped with 10 trays of packing. In order to make the gas-liquid two-phase distribution in the tower more evenly, a 25cm-high ordinary packing is installed between the fifth and sixth trays. The use of the catalytic distillat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com