Large reciprocating feeder

A reciprocating feeder technology, which is applied in the field of large reciprocating feeders, can solve the problems of difficulty in adjusting the stroke of the feeder, difficulty in reaching the operator, and insufficient strength of the feeder, so as to achieve balanced force and high performance. Excellent, rigidity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

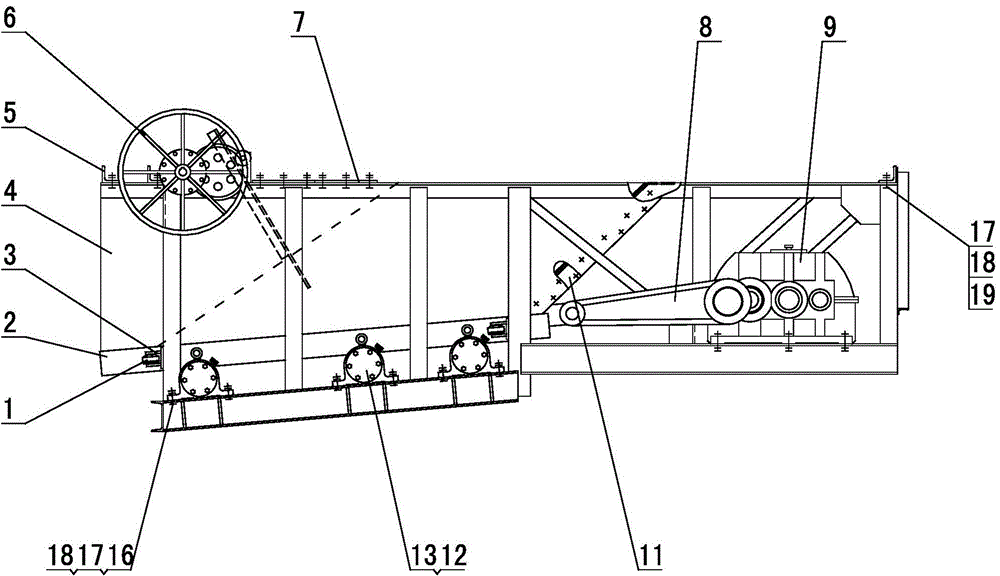

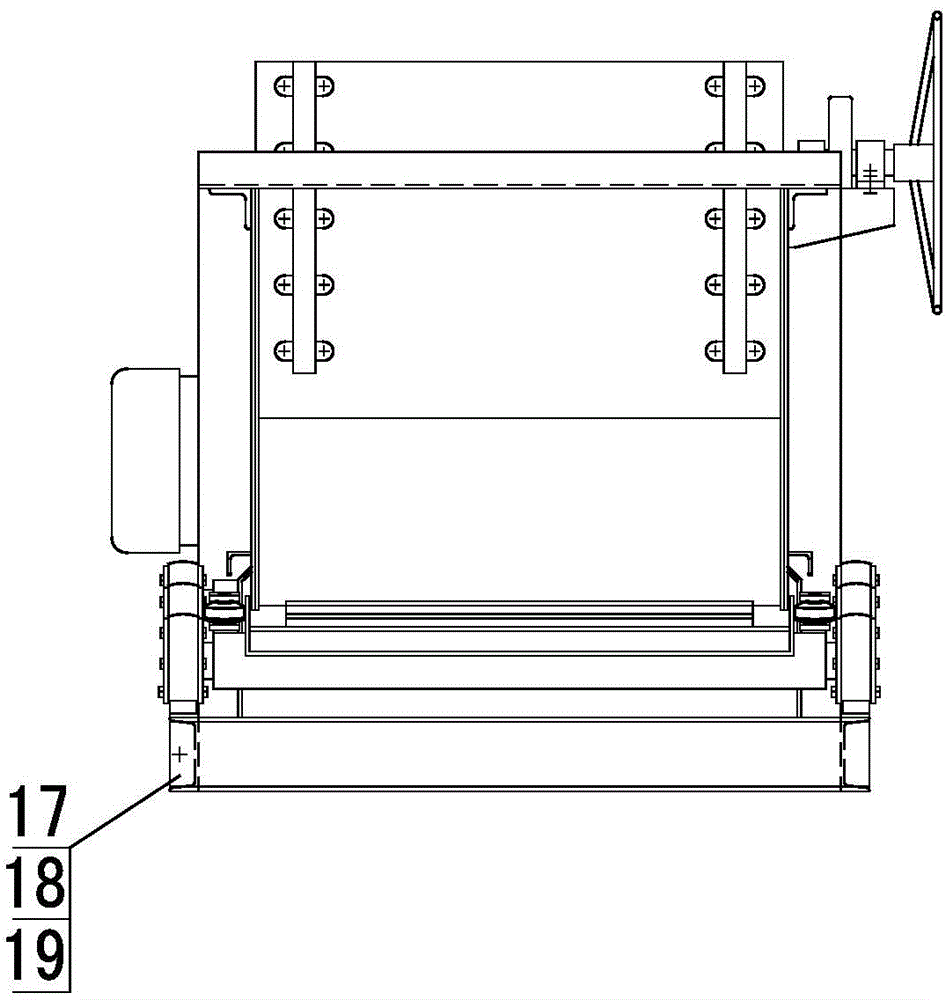

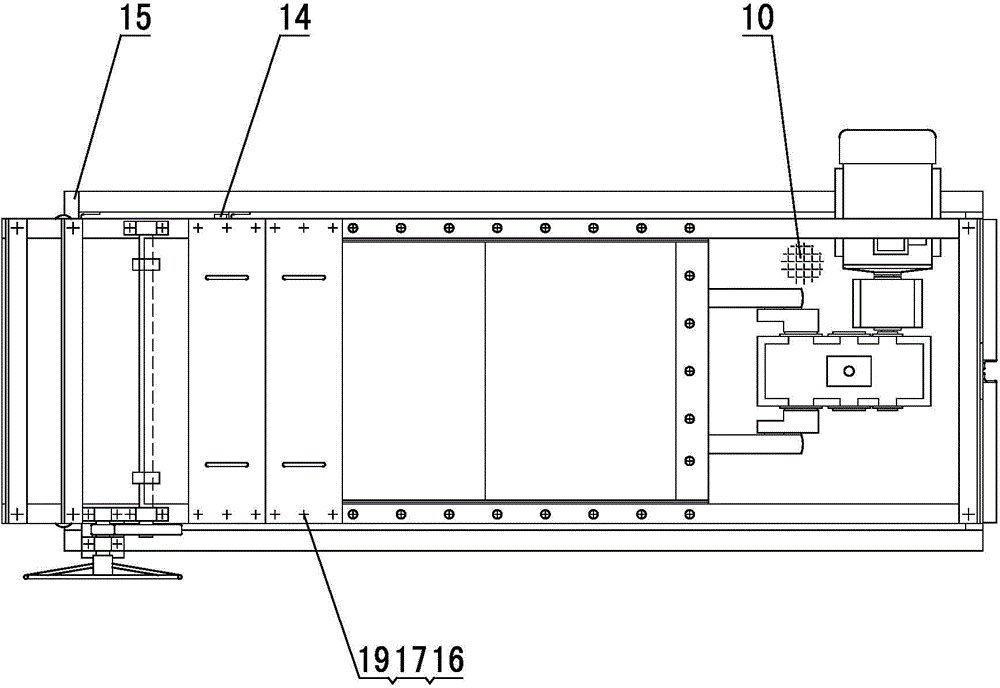

[0020] A large reciprocating feeder, such as attached Figure 1-3 As shown, it mainly includes a material guide trough, a support frame, a driving device 9, a bracket 3, a crank connecting rod device 8 and an adjustment gate 6, and the driving device 9 is connected to the crank connecting rod device 8 on one side of the material guide tank, and the crank connecting rod device 8 is connected to the crank connecting rod device 8. The rod device 8 is installed on the support frame, and the adjusting gate 6 is located at the discharge port of the material guide groove. The main assembly structure is that the feed trough is welded by steel plates into a semi-closed groove shape at the top, a cover plate 7 is arranged on the top of the feed trough, so that the feed trough is in a semi-closed state, and the cover plate 7 at the head end is formed by The hand wheel and the screw r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com