Fully automatic CNC circular welding machine

A fully automatic, electric welding machine technology, applied in the direction of electric heating devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult welding, uneven weld seam, uncontrollable weld seam size, etc., and achieve accurate butt joint and adjustable weld seam size Adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

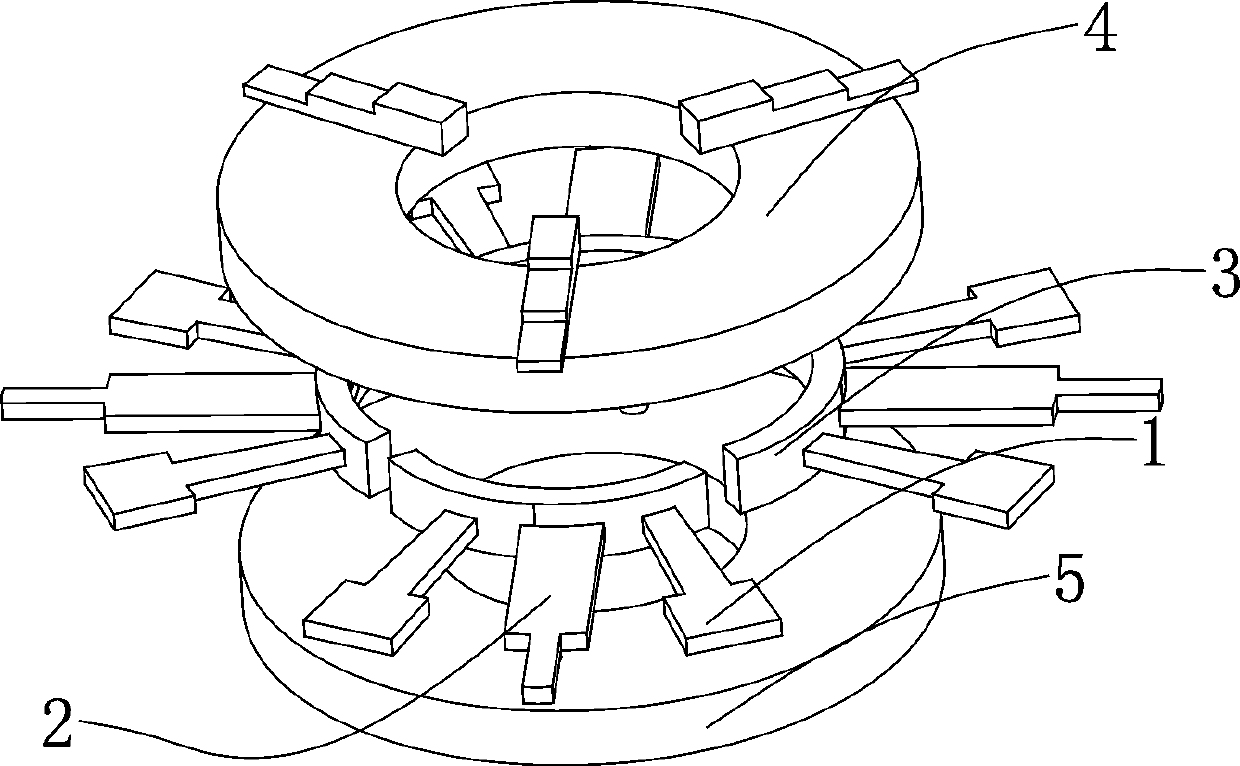

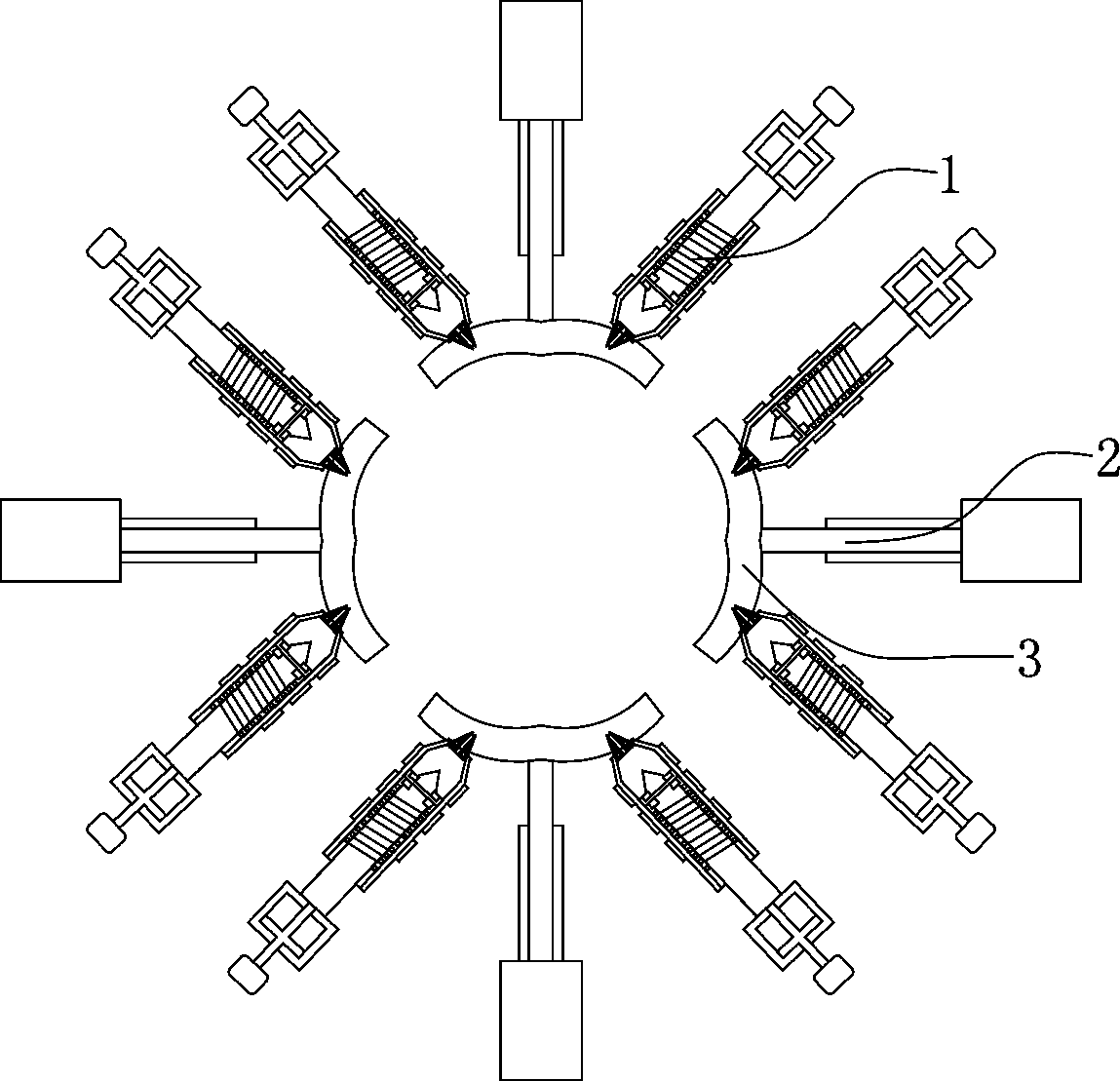

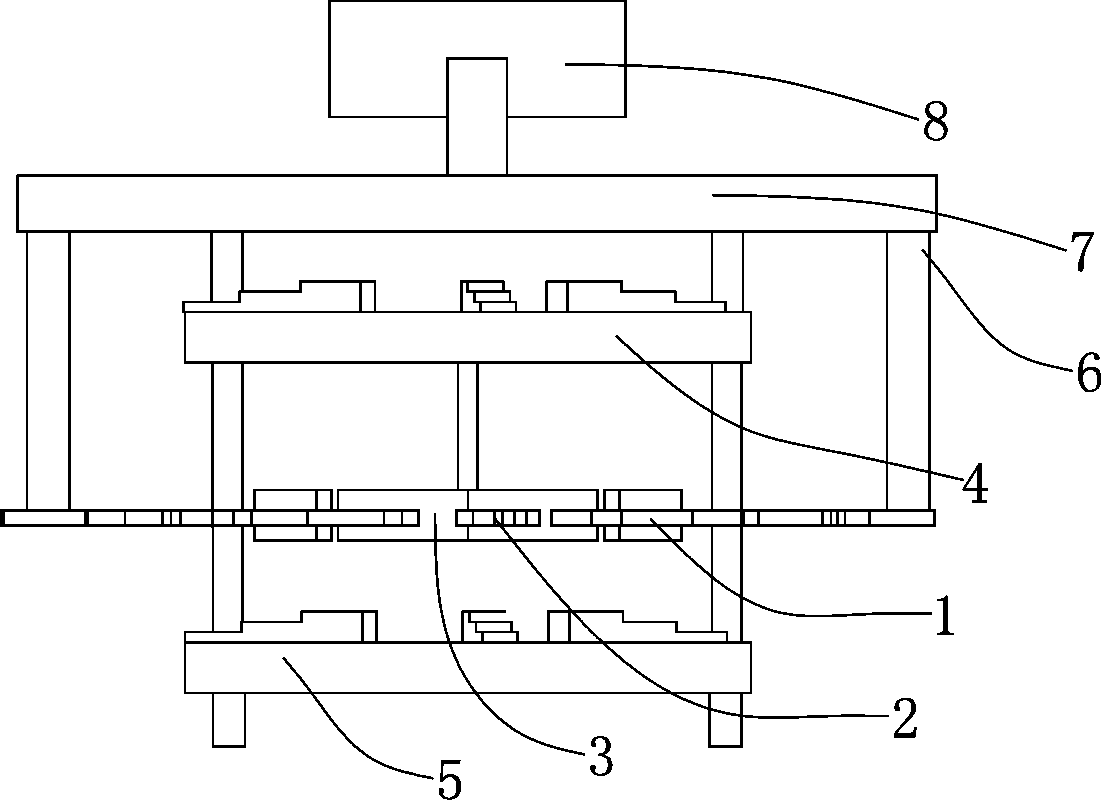

[0020] The full-automatic numerically controlled annular electric welding machine includes a plurality of arc-shaped welding blocks 3, the arc-shaped welding blocks 3 form a ring shape, and an output port 31 is opened on the arc-shaped welding blocks 3, and the arc-shaped welding blocks 3 The block 3 is a hollow shell, the shell is divided into two layers, the inner layer material is tungsten, the outer layer material is aluminum, and the arc welding block 3 includes a left arc block and a right arc block connected as one Shaped block, the angle of the left arc block and the right arc block is between 50 degrees and 60 degrees, the middle of the arc welding block 3 is connected with a sliding mechanism, the left arc block and the right The arc-shaped block is provided with a tin feeding mechanism 1, the sliding mechanism and the tin feeding mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com