Installing and guiding system of propping-tensioning vertical pipe and using and recovery methods thereof

A guiding system and top tensioning technology, applied in drilling pipe, casing, earthwork drilling and production, etc., can solve the problems of increased project investment, increased wellhead chassis size, control cable winding, etc., achieving high safety factor, The effect of simple and low-cost installation and recovery equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

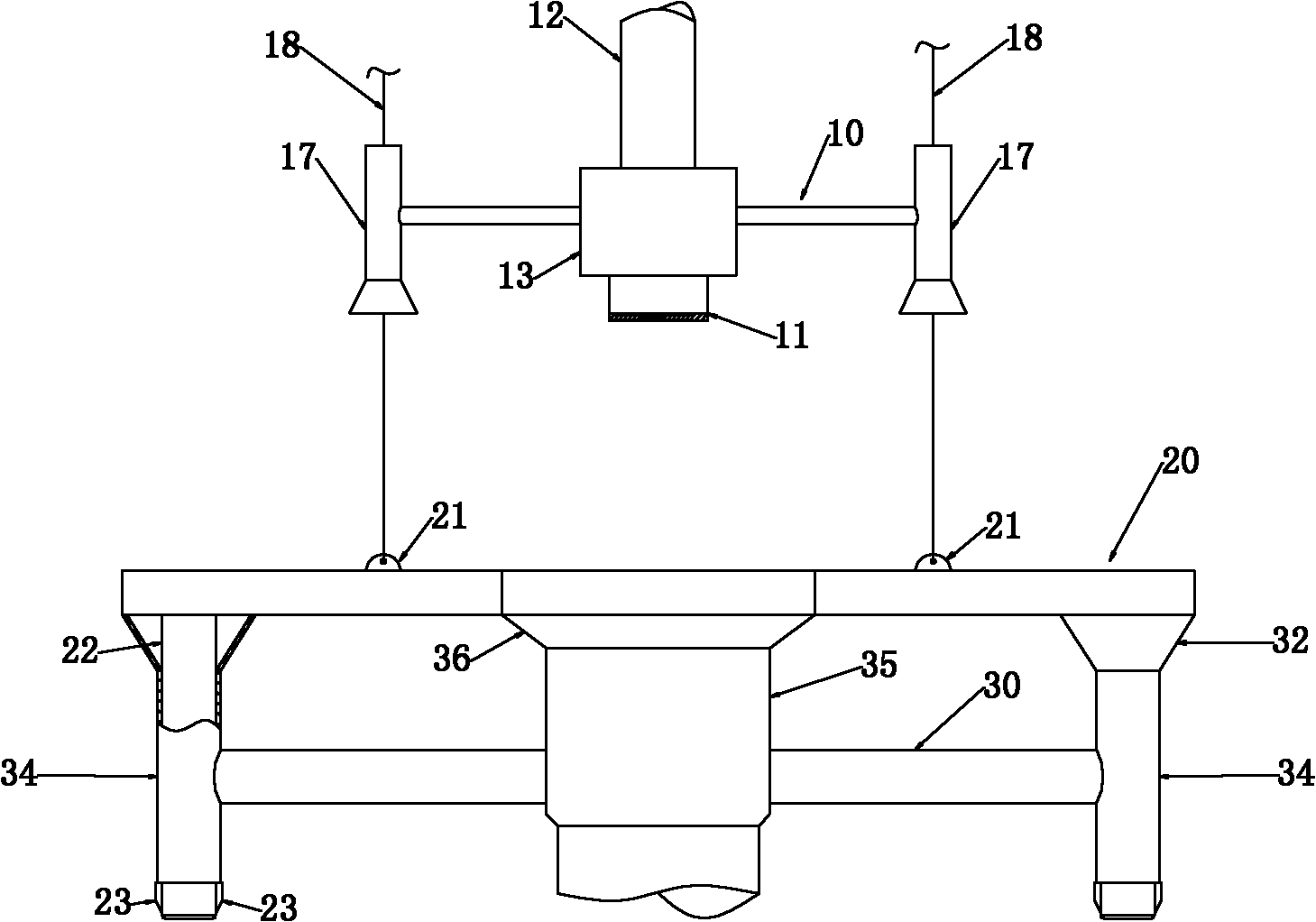

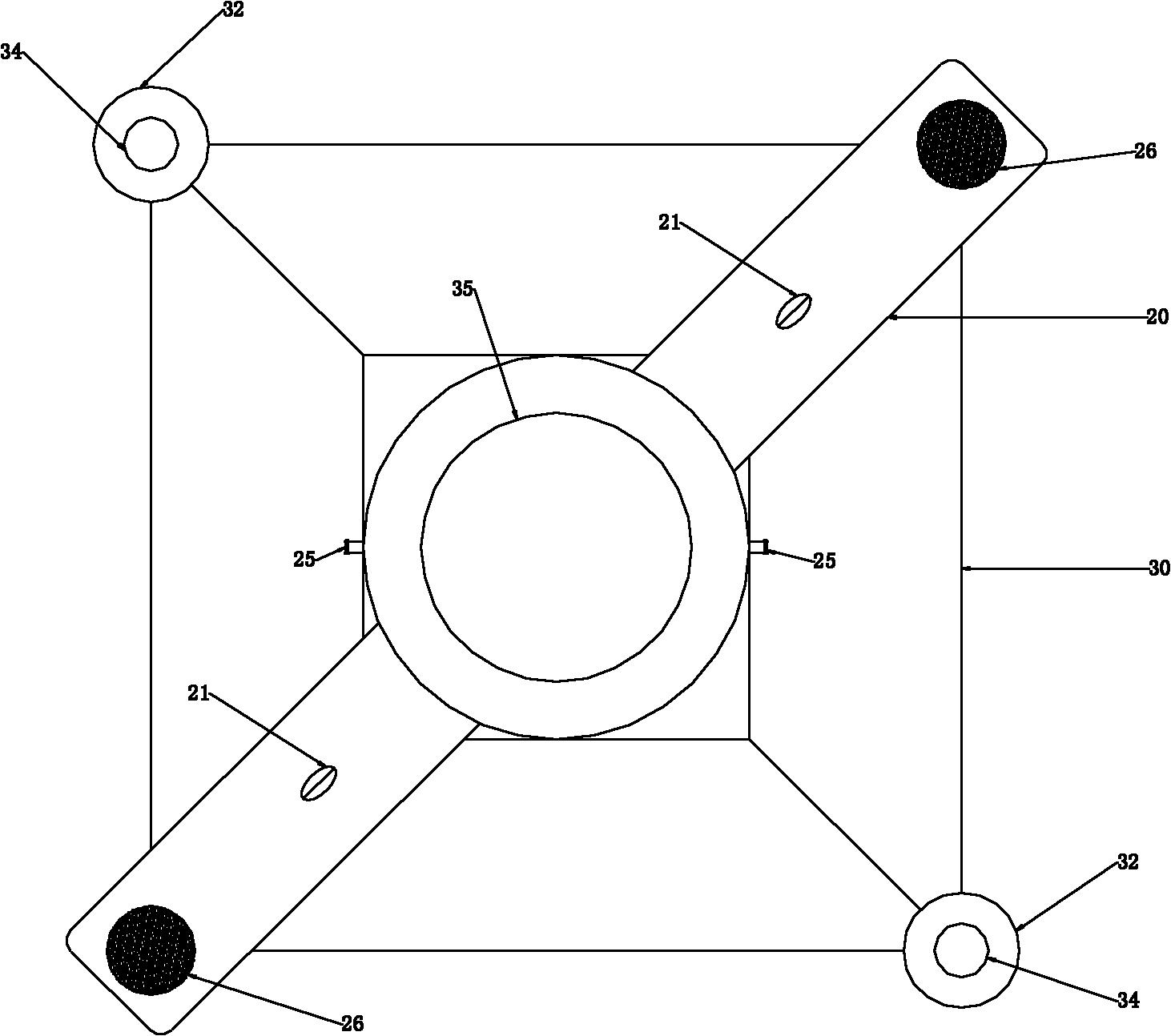

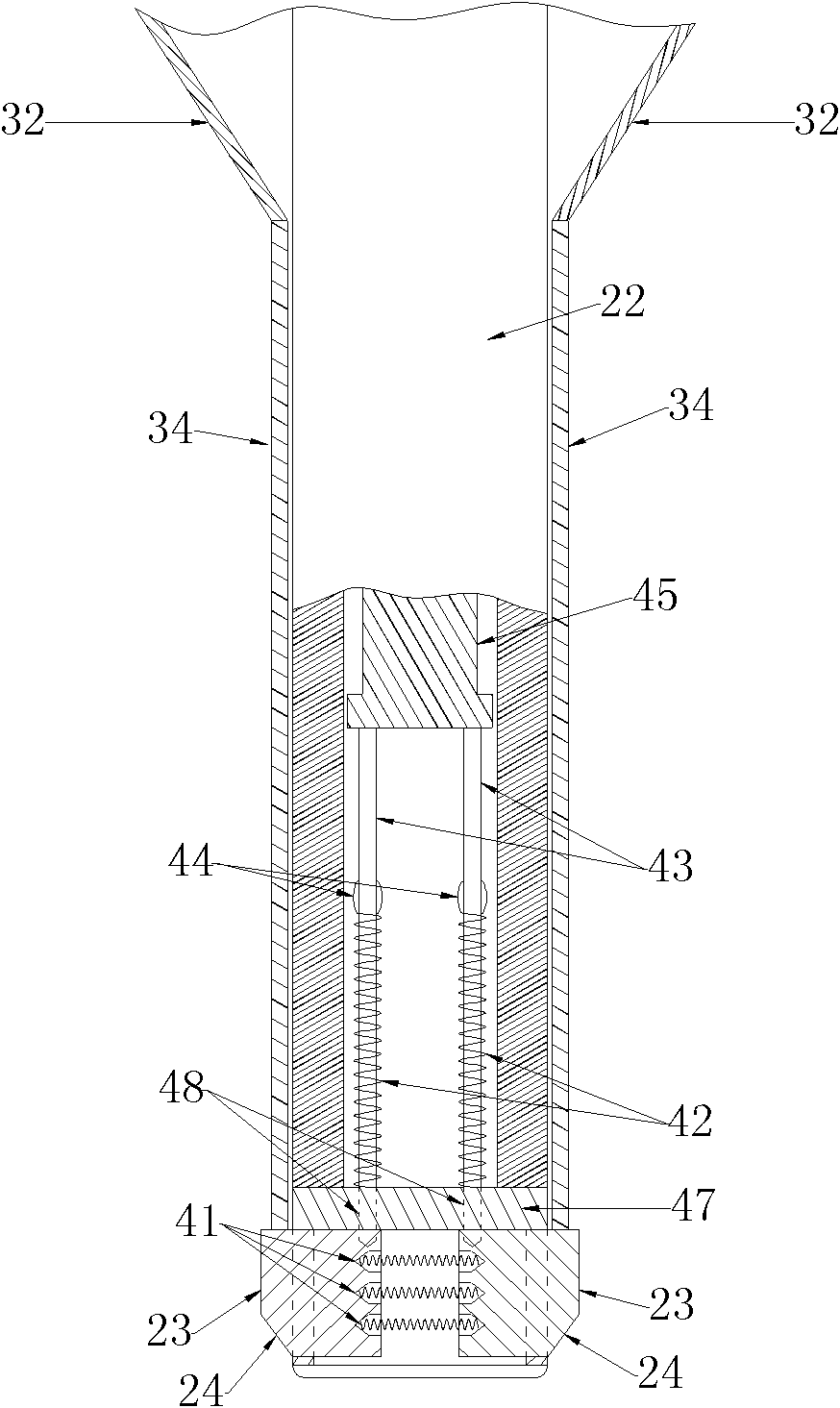

[0031] The present invention will be further described below in conjunction with the accompanying drawings. like Figure 1-3 As shown, a top tensioning riser installation guide system includes a guide frame 10 and a temporary guide base 20;

[0032] The guide frame 10 includes a lowering member 13 and a guide cylinder 17, the left and right sides of the lowering member 13 are fixedly connected to the guide cylinder 17 through a transverse link, and the two sides of the lowering mechanism 13 are symmetrically installed with Shackle 25; described guide cylinder 17 has longitudinal slit (not shown in the figure), is embedded with guide rope 18 in the described slit, and described guide rope 18 can slide up and down in the slit, and It can be taken out or embedded in the slit multiple times. The upper end of the guide rope 18 is connected to the guide rope tensioner on the offshore platform, and its lower end is connected to the suspension ring 21 of the temporary guide base 20. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com