Electrode material applied to supercapacitor

A technology of supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of low load and difficult to obtain practical use, achieve uniform pore size, improve comprehensive electrochemical performance, technology simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

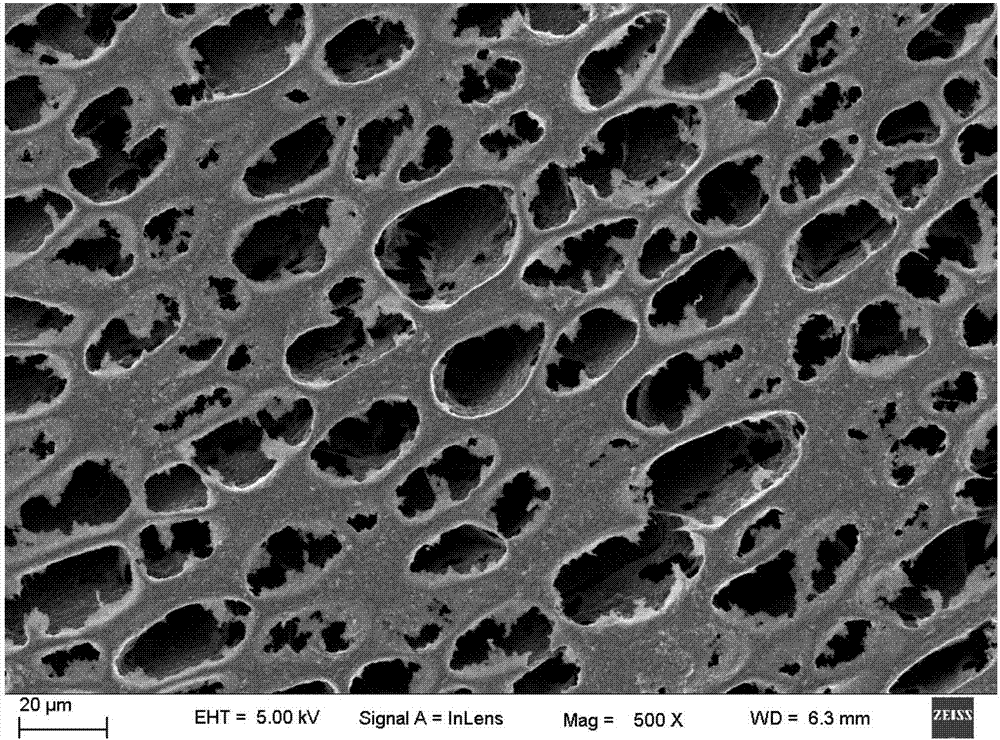

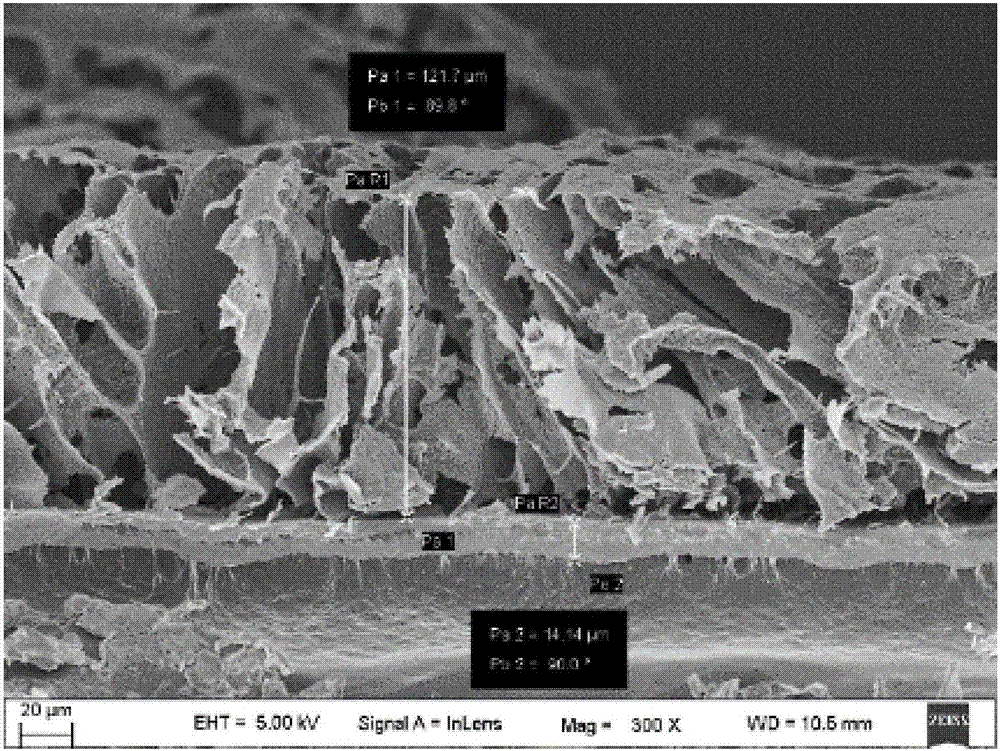

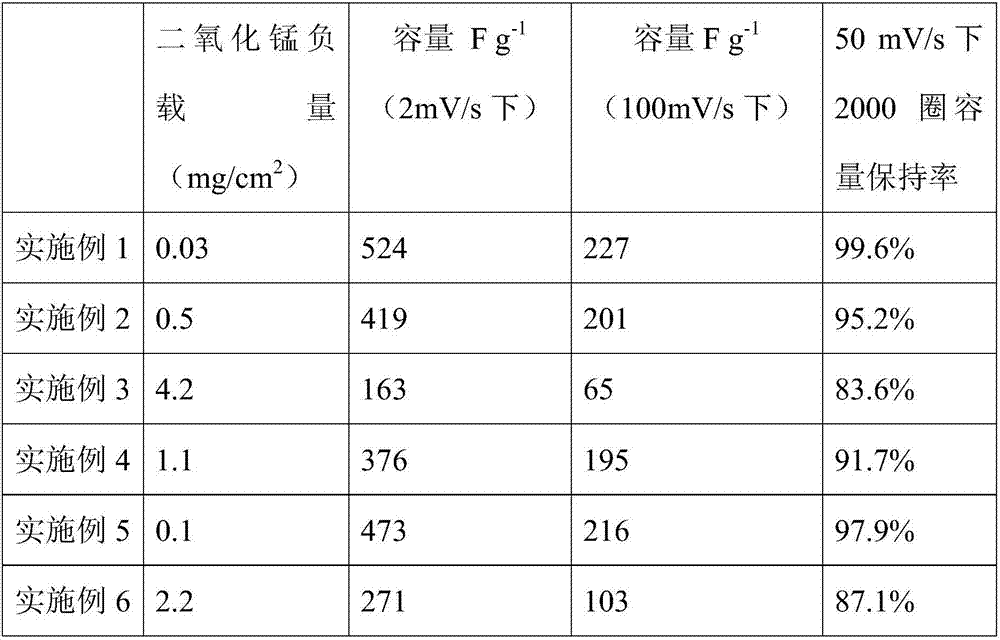

[0025] Prepare a carbon nanotube skeleton with a vertical through-hole film structure: disperse carbon nanotubes with a concentration of 4wt% and 0.9wt% polypropylene pyrrolidone in deionized water to make a uniform dispersion, and then add 48wt% SBR water-based binder, after stirring, obtain a viscous carbon nanotube water dispersion slurry, the mass ratio of the SBR and the carbon nanotube is 9:1, and then the slurry is coated on the On stainless steel foil, the coating film thickness was 120 μm. Then fix the stainless steel foil coated with slurry on the glass sheet, then place the glass sheet in a hollow mold, and then push the mold into a cold trap at -196°C at 50cm / h until the slurry is completely solidified Afterwards, it was quickly transferred to a freeze dryer, and freeze-dried at -10°C with a final vacuum controlled at 5Pa to obtain a carbon nanotube framework with a vertical through-hole film structure. The horizontal section of the framework and The SEM of the ve...

Embodiment 2

[0029] Prepare a carbon nanotube skeleton with a vertical through-hole film structure: disperse carbon nanotubes with a concentration of 5wt% and sodium dodecylsulfonate at 1.2wt% in deionized water to make a uniform dispersion, and then disperse the Add 48wt% of the SBR water-based binder to the liquid, stir to obtain a viscous carbon nanotube water dispersion slurry, the mass ratio of the SBR and the carbon nanotube is 12:1, and then the slurry is coated with Coated on stainless steel foil with a film thickness of 250 μm. Then fix the stainless steel foil coated with slurry on the glass sheet, then place the glass sheet in a hollow mold, and then push the mold into a cold trap at -196°C at 35cm / h until the slurry is completely solidified Afterwards, it was quickly transferred to a freeze dryer, and freeze-dried at -5°C with a final vacuum of 1 Pa to obtain a carbon nanotube skeleton with a vertical through-hole film structure. The average diameter of the vertical through ho...

Embodiment 3

[0033] Prepare a carbon nanotube skeleton with a vertical through-hole film structure: disperse carbon nanotubes with a concentration of 3wt% and 0.6wt% sodium cholate in deionized water to make a uniform dispersion, and then add 48wt% SBR water-based binder, after stirring, obtain a viscous carbon nanotube water dispersion slurry, the mass ratio of the SBR and the carbon nanotube is 7:1, and then the slurry is coated on the On stainless steel foil, the coating film thickness was 400 μm. Then fix the stainless steel foil coated with slurry on the glass sheet, then place the glass sheet in a hollow mold, and then push the mold into a cold trap at -196°C at 20cm / h until the slurry is completely solidified Afterwards, it was quickly transferred to a freeze dryer, and freeze-dried at -5°C with a final vacuum of 1 Pa to obtain a carbon nanotube skeleton with a vertical through-hole film structure. The average diameter of the vertical through holes is 17 μm, and the wall thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com