Method for manufacturing optical compound film structure with controllable transparency pattern changes

An optical composite film and manufacturing method technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of long production cycle, inability to achieve continuous production, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

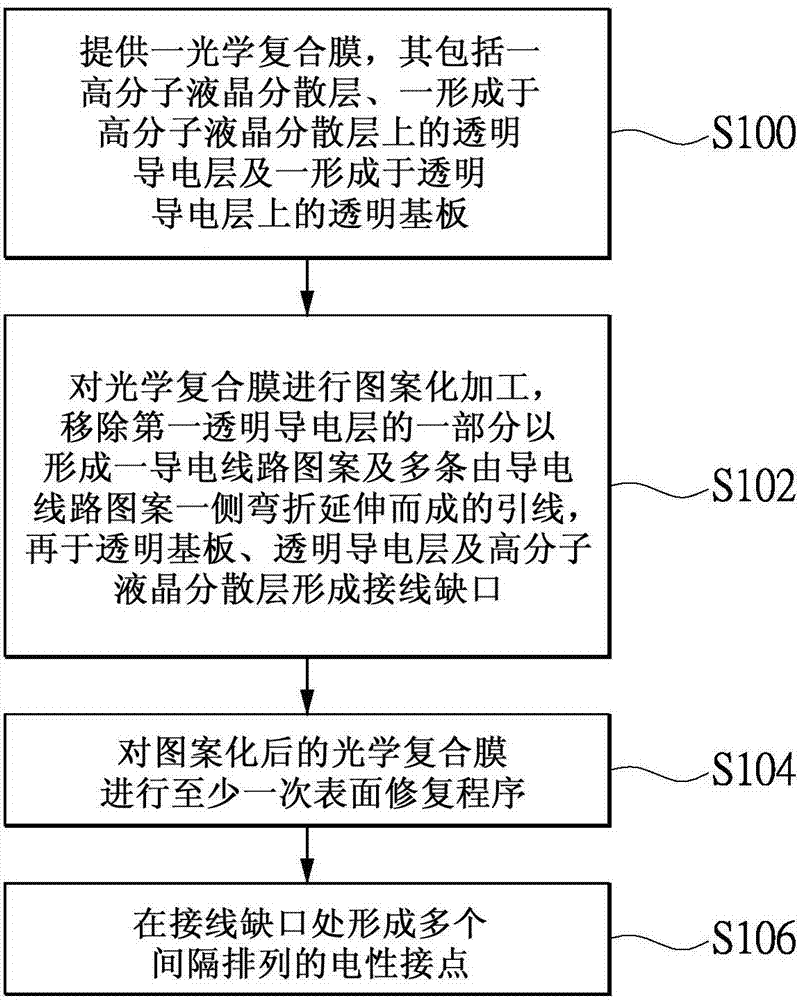

[0027] see figure 1 , is a schematic flowchart of the manufacturing method of the optical composite film structure capable of controlling the change of the light transmission pattern according to the first embodiment of the present invention. And please refer to Figure 2A to Figure 9 , is a process schematic diagram corresponding to the manufacturing method of this embodiment.

[0028] The manufacturing method of this embodiment is suitable for manufacturing an optical composite film structure with a polymer dispersed liquid crystal (PDLC) layer, wherein the polymer dispersed liquid crystal layer is formed with a conductive circuit pattern and a lead circuit, and the lead circuit can be connected to the outside through the wiring. The control unit is electrically connected, so the optical composite film structure can pass through the control unit to make the area on the polymer dispersed liquid crystal layer related to the conductive circuit pattern produce a partial light t...

no. 2 example

[0042] see Figure 10 , is a schematic flowchart of the manufacturing method of the optical composite film structure capable of controlling the change of the light transmission pattern according to the second embodiment of the present invention. Such as Figure 10 As shown, the manufacturing method of this embodiment includes: Step S200, providing an optical composite film, which includes a polymer liquid crystal dispersion layer, a transparent conductive layer formed on the polymer liquid crystal dispersion layer, and a transparent conductive layer formed on the transparent conductive layer. a transparent substrate; step S202, performing at least one surface repair procedure on the optical composite film; step S204, patterning the surface repaired optical composite film, removing a part of the first transparent conductive layer to form a conductive circuit pattern and A plurality of lead wires formed by bending and extending one side of the conductive circuit pattern, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com