Waste cloth regenerating and reusing device and recycling method thereof

A cloth and material roller technology, which is applied in the field of waste cloth regeneration and recycling devices, can solve the problems of destroying the ecological environment and waste of resources, and achieve the effects of improving the environment, reducing investment, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

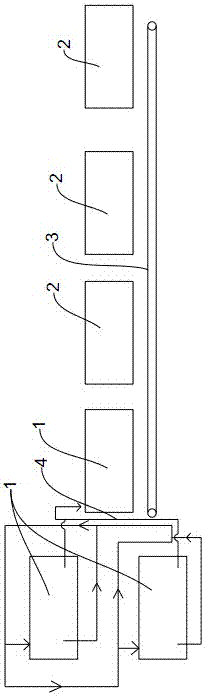

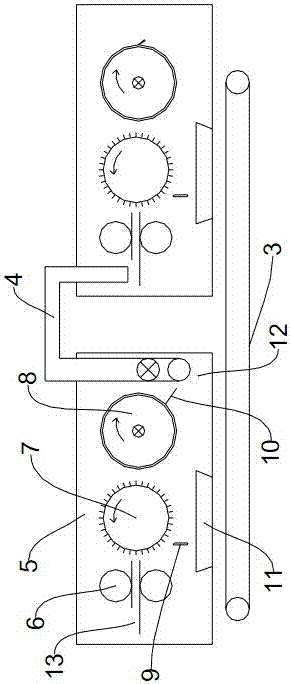

[0019] Such as figure 1 , figure 2 As shown, a waste cloth recycling device described in this embodiment includes a loosening mechanism 1 and a combing mechanism 2, and the loosening mechanism 1 includes a frame 5 and a power mechanism, and is set on the frame 5 There is a feed area 13, two pressure rollers 6 are arranged up and down at the output port of the feed area 13, and a licker roller 7 is arranged at the output port of the feed area 13, and the licker roller 7 and the feed area 13 There is a gap at the output port of the burr roller 7, and the rotation direction of the burr roller 7 on the side of the feed area 13 is from top to bottom; based on the material conveying direction, a hollow suction roller 8 is arranged in front of the burr roller 7 , the surface of the suction roller 8 is provided with a mesh, and one end of the suction roller 8 is connected with the suction fan; the rotation direction of the suction roller 8 is opposite to that of the bristle roller 7...

Embodiment 2

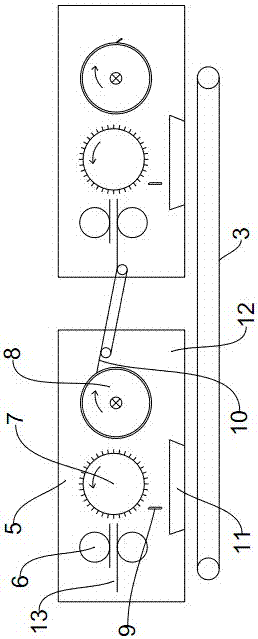

[0025] Such as image 3 As shown, a waste cloth recycling device described in this embodiment includes a loosening mechanism 1 and a combing mechanism 2, and the loosening mechanism 1 includes a frame 5 and a power mechanism, and is set on the frame 5 There is a feed area 13, two pressure rollers 6 are arranged up and down at the output port of the feed area 13, and a licker roller 7 is arranged at the output port of the feed area 13, and the licker roller 7 and the feed area 13 There is a gap at the output port of the burr roller 7, and the rotation direction of the burr roller 7 on the side of the feed area 13 is from top to bottom; based on the material conveying direction, a hollow suction roller 8 is arranged in front of the burr roller 7 , the surface of the suction roller 8 is provided with a mesh, and one end of the suction roller 8 is connected with the suction fan; the rotation direction of the suction roller 8 is opposite to that of the bristle roller 7; The blanki...

Embodiment 3

[0030] This embodiment describes a method for recycling waste cloth using the device in Embodiment 1. First, the waste cloth is screened with the same color, and the waste cloth of different colors is separated, and the waste cloth of the same color is processed and utilized; The colored waste cloth is put into the loosening mechanism 1 to loosen it, and the loosened fiber is transported from the discharge area 12 to the next loosening mechanism 1 for another loosening process, and the fiber after being loosened again passes through eight The combing mechanism 2 combs, finally forms regenerated fiber, and then utilizes the regenerated fiber to carry out spinning; wherein the diameter of the depilatory roller 7 of the loosening mechanism 1 is 68cm, and the rotating speed is 850 rev / min, and the depilatory roller 7 of the carding mechanism The diameter is 29cm, and the rotation speed is 2000 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com