A two-phase anaerobic treatment device and process based on magnetite and activated carbon reinforcement

An anaerobic treatment and activated carbon technology, which is applied in the field of anaerobic biological treatment process, can solve the problems of limited application of two-phase anaerobic process, slow mutual support and metabolism of methane production, low efficiency of acidification phase hydrolysis and acidification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

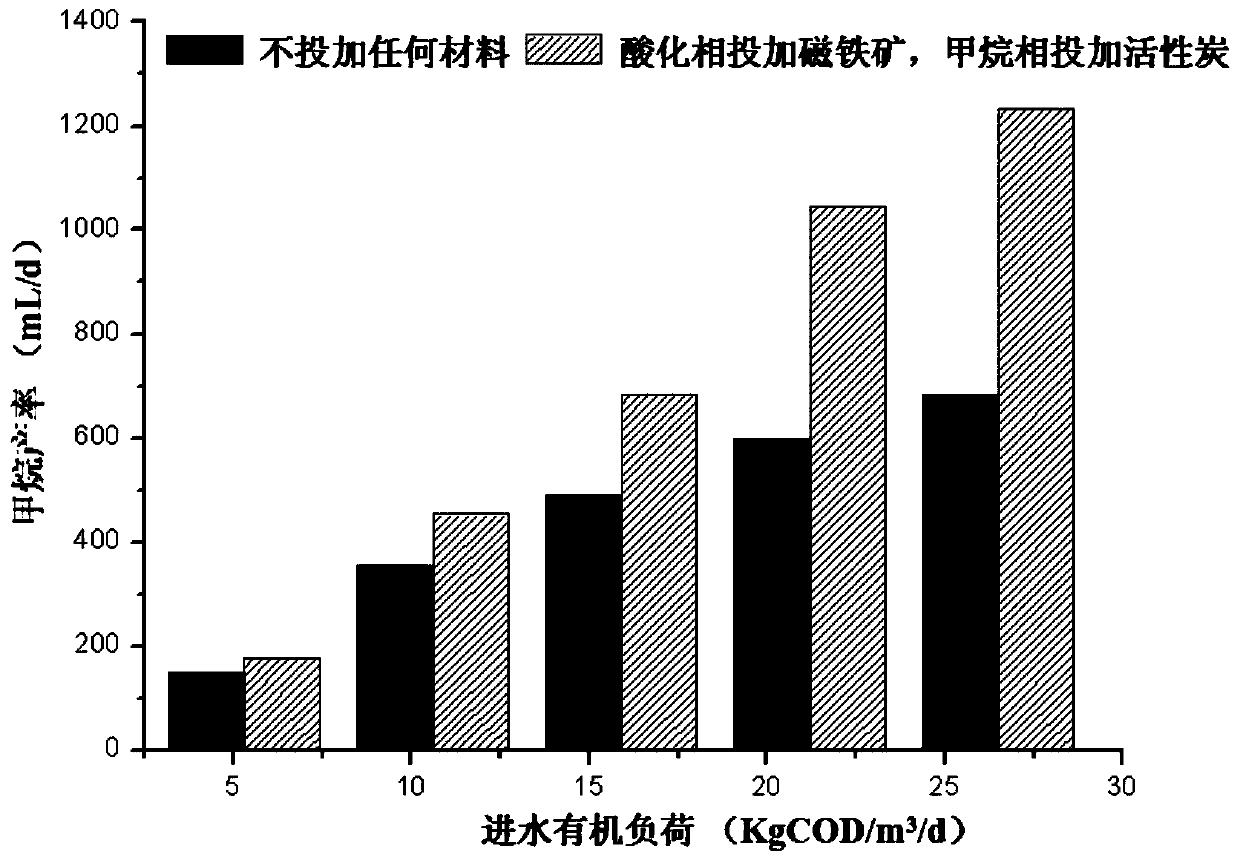

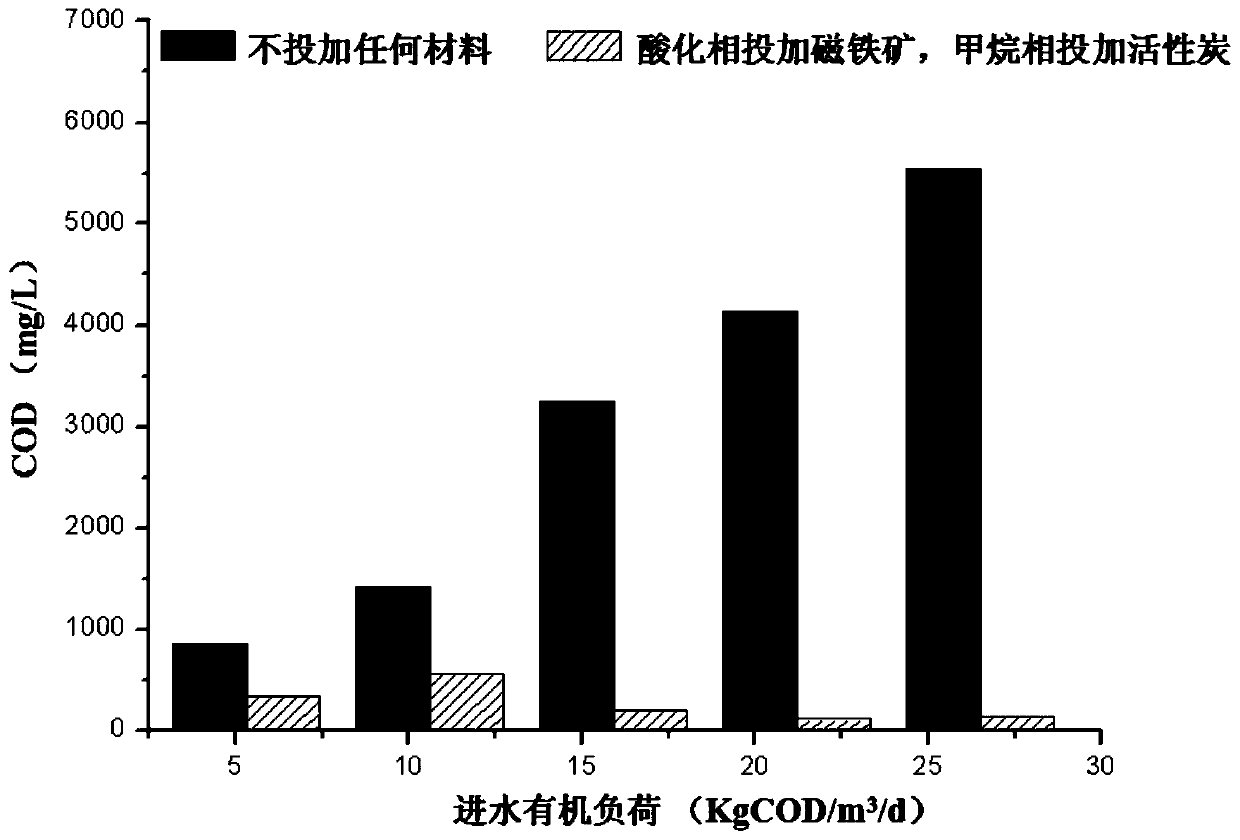

[0029] The application mechanism of this two-phase anaerobic process based on magnetite and activated carbon enhancement is: 1. In an anaerobic environment, iron-reducing microorganisms can transfer the generated electrons to extracellular insoluble ferric iron while metabolizing organic matter. substances (such as magnetite), so that Fe 3+ is reduced to Fe 2+ ——Reduction process of dissimilated iron. The dissimilatory iron reduction process can provide growth support for iron-reducing microorganisms, and then enrich iron-reducing microorganisms. Iron-reducing microorganisms have the ability to decompose macromolecular complex organic substances (such as sugars, proteins and lipids, etc.). In addition, the acidic anaerobic environment (pH<7.0) is thermodynamically favorable for the reduction process of dissimilated iron.

[0030] 2. Adding conductive carbon materials to anaerobic sludge can build and strengthen DIET—a new mechanism of microbial intertrophy metabolism that c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com