Wood grinding rotor for wood grinder

A wood chipper and wood chipping technology, which is applied in the field of mechanical equipment, can solve the problems of increasing equipment volume, high noise, and high risk, and achieve the effects of reducing inertial impact force, long service life, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

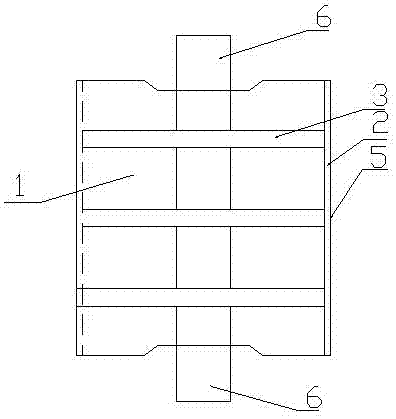

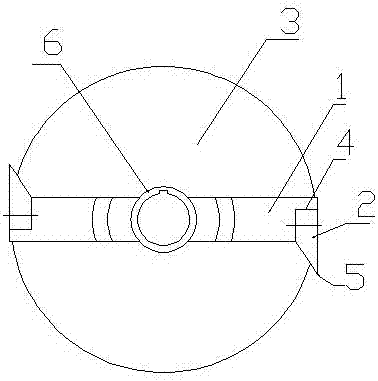

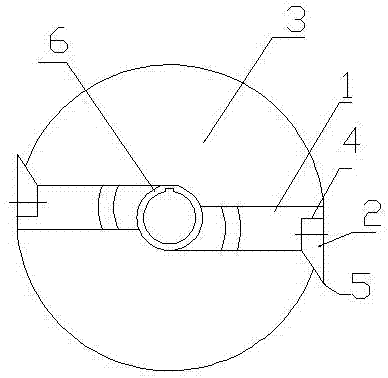

[0026] For ease of description, below in conjunction with accompanying drawing, the wood chipping rotor of invention is described in detail.

[0027] Such as Figure 1-6 As shown in , a wood shredding rotor for a wood shredder includes a mounting frame 1, a blade 2 is provided on the outside of the mounting frame 1, there are two or more mounting frames 1, and the mounting frame is flat , When the mounting frame rotates, the side can be used to blow air to form a blowing impeller. The mounting frame 1 rotates to generate wind, and the wind force is stronger under high-speed rotation, and the crushed sawdust can be discharged from the discharge port. Through experiments, the discharge distance reaches 10-15m.

[0028] The mounting frame is arranged in a circular array, and the mounting frame is two, and the two adjacent mounting frames are plate-shaped with an integrated structure, such as figure 2 , 3 , Shown in 5, 6, two kinds of situations all can, the one side position a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com