Preparation method of high-safety ternary composite material

A composite material, high-safety technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as good safety performance and poor rate performance, and achieve the effect of maintaining safety, high compatibility, and improving safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

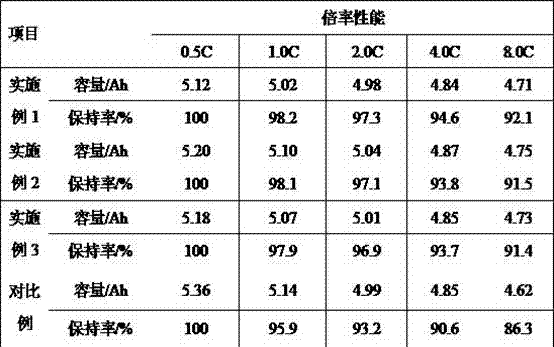

Examples

Embodiment 1

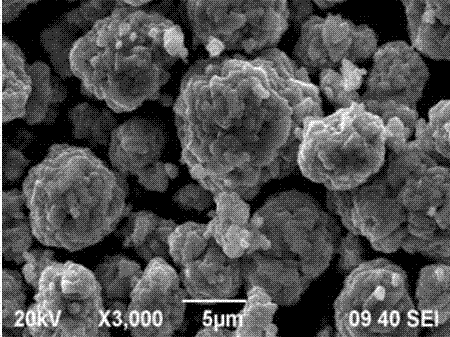

[0019] Depend on figure 1 Known, a kind of preparation method of high safety ternary composite material, by weight percentage, comprises the following steps:

[0020] 1. Preparation of mixed slurry:

[0021] First, add 15g of polyvinylidene fluoride to 500ml of trimethylhexyl bis(trifluoromethylsulfonyl)imide ionic liquid, after the dispersion is uniform, add 20g of Li 3 PMo 12 o 40 Porous metal lithium oxide compound, 20gLi 5 La 3 Ta 2 o 12 Inorganic lithium compound, after stirring evenly, add 100g LiNi 0.3 co 0.5 mn 0.2 o 2 Ternary materials, and through a high-speed disperser, LiNi coated with lithium compounds is obtained 0.3 co 0.5 mn 0.2 o 2 Ternary composite material A;

[0022] 2. Sintering and carbonization:

[0023] LiNi 0.3 co 0.5 mn 0.2 o 2 The ternary composite material A was transferred to a tube furnace, and in an inert atmosphere, the temperature was raised to 250°C at a heating rate of 5°C / min, and kept for 2 hours, and then the temperatur...

Embodiment 2

[0027] 1. Preparation of mixed slurry:

[0028] First, 10g of polyvinyl alcohol was added to 500ml of N-methyl-N-propylpiperidine bis(trifluoromethylsulfonyl)imide (PP13TFSI) ionic liquid, and after the dispersion was uniform, 10g of Li 3 PW 12 o 40 Porous metal lithium oxide compound, 10gLi 5 La 3 Nb 2 o 12 Inorganic lithium compound, after stirring evenly, add 100g LiNi 0.3 co 0.5 mn 0.2 o 2 Ternary materials, and through a high-speed disperser, LiNi coated with lithium compounds is obtained 0.3 co 0.5 mn 0.2 o 2 Ternary composite material A;

[0029] 2. Sintering and carbonization:

[0030] LiNi 0.3 co 0.5 mn0.2 o 2 The ternary composite material A was transferred to a tube furnace, and in an inert atmosphere, the temperature was raised to 200°C at a heating rate of 1.0°C / min, and kept for 3 hours, and then the temperature was raised to 600°C at a heating rate of 1.0°C / min, and kept warm 3h, then naturally cool down to room temperature to obtain the ternar...

Embodiment 3

[0034] 1. Preparation of mixed slurry:

[0035] First, add 20g of polymethyl acrylate binder to 500ml of trimethylhexyl bis(trifluoromethylsulfonyl)imide ionic liquid, after the dispersion is uniform, add 30g of Li 4 SiW 12 o 40 Porous metal lithium oxide, 30g LiAlO 2 , after stirring evenly, add 100g LiNi 0.3 co 0.5 mn 0.2 o 2 Ternary materials, and through a high-speed disperser, LiNi coated with lithium compounds is obtained 0.3 co 0.5 mn 0.2 o 2 Ternary composite material A;

[0036] 2. Sintering and carbonization:

[0037] LiNi 0.3 co 0.5 mn 0.2 o 2 The ternary composite material A was transferred to a tube furnace, and in an inert atmosphere, the temperature was raised to 300°C at a heating rate of 10°C / min, and kept for 1 hour, and then the temperature was raised to 900°C at a heating rate of 10°C / min, and kept 1h, then naturally cooled to room temperature to obtain LiNi 0.3 co 0.5 mn 0.2 o 2 Ternary composite material B;

[0038] 3. Electrochemical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com