Vacuum drying method for phoebe zhennan board

A technology of vacuum drying and nanmu, which is applied in the direction of wood drying, preliminary treatment to promote the drying of solid materials, and drying of solid materials. The effect of moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

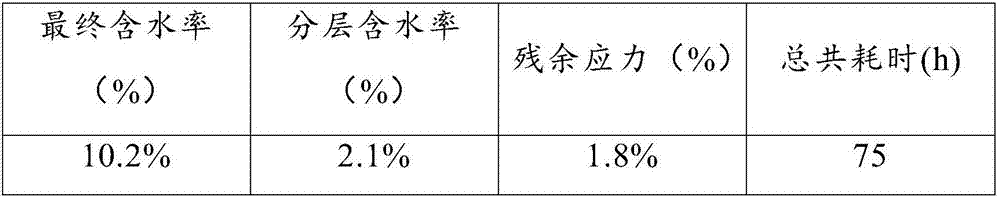

Embodiment 1

[0023] This embodiment adopts 1000mm (length) * 100mm (width) * 30mm thick nanmu plank to carry out vacuum drying, and concrete steps are as follows:

[0024] (1) The 30mm thick nanmu boards are separated and stacked in the drying equipment by pads; preheated with 100°C saturated steam, the preheating time is 4.5 hours;

[0025] (2) Start vacuuming when the temperature of the wood core layer is naturally cooled to 50°C. The absolute pressure in the equipment is controlled to 0.008MPa. Stop vacuuming after about 30 minutes of vacuuming, and open the vacuum valve to release the vacuum, so that the drying equipment returns to normal pressure. ;

[0026] (3) Heating the wood, using 60°C steam heating, the dry bulb and wet bulb temperatures of the psychrometer are controlled at 60°C and 55°C respectively, when the temperature of the wood center layer reaches 50°C, stop heating, and the fan continues to run for 30 minutes;

[0027] (4) Vacuumize for 30 minutes, control the absolute...

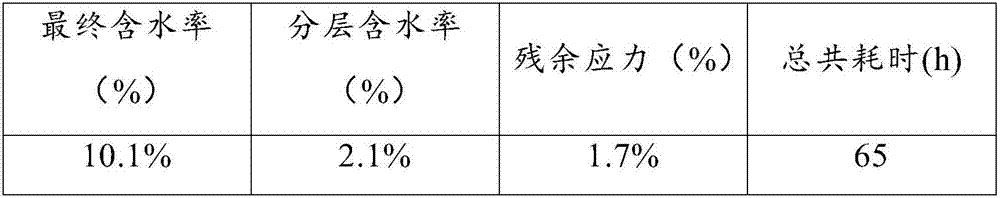

Embodiment 2

[0033] This embodiment adopts 1000mm (length) * 100mm (width) * 30mm thick nanmu plank to carry out vacuum drying, and concrete steps are as follows:

[0034] (1) The 30mm thick nanmu boards are separated and stacked in the drying equipment by pads; preheated with 100°C saturated steam, the preheating time is 4.5 hours;

[0035] (2) Start vacuuming when the temperature of the wood core layer is naturally cooled to 50°C. The absolute pressure in the equipment is controlled to 0.012MPa. Stop vacuuming after about 30 minutes of vacuuming, and open the vacuum valve to release the vacuum, so that the drying equipment returns to normal pressure. ;

[0036] (3) To heat the wood, use 60°C steam to heat it. The dry bulb and wet bulb temperatures of the psychrometer are controlled at 60°C and 55°C respectively. When the temperature of the wood center layer reaches 50°C, stop heating, and the fan continues to run for 30 minutes;

[0037](4) Vacuumize for 30 minutes, control the absolute...

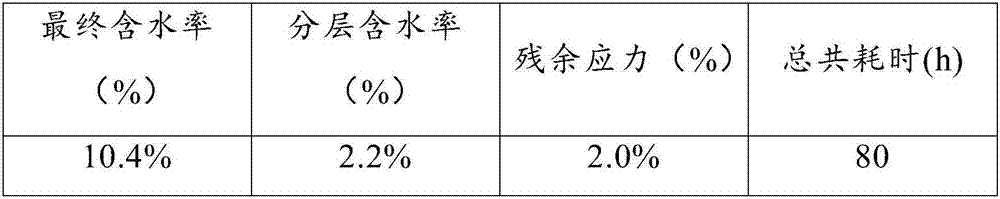

Embodiment 3

[0043] This embodiment adopts 1000mm (length) * 100mm (width) * 30mm thick nanmu plank to carry out vacuum drying, and concrete steps are as follows:

[0044] (1) The 30mm thick nanmu boards are separated and stacked in the drying equipment with pads; preheated with 100°C saturated steam for 4.5 hours.

[0045] (2) Start vacuuming when the temperature of the wood core layer is naturally cooled to 50°C. The absolute pressure in the equipment is controlled to 0.008MPa. Stop vacuuming after about 30 minutes of vacuuming, and open the vacuum valve to release the vacuum, so that the drying equipment returns to normal pressure. ;

[0046] (3) Heating the wood, using 50°C steam heating, the dry bulb and wet bulb temperatures of the psychrometer are controlled at 58°C and 55°C respectively, when the temperature of the wood center layer reaches 45°C, stop heating, and the fan continues to run for 20 minutes;

[0047] (4) Vacuumize for 30 minutes, control the absolute pressure in the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com