Electroless Copper Plating Solution And Electroless Copper Plating Method For Increasing Flatness Of Copper Coating

A technology of electroless copper plating and copper plating, applied in coating, liquid chemical plating, metal material coating process, etc., can solve problems such as inability to know, and achieve the effect of high flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

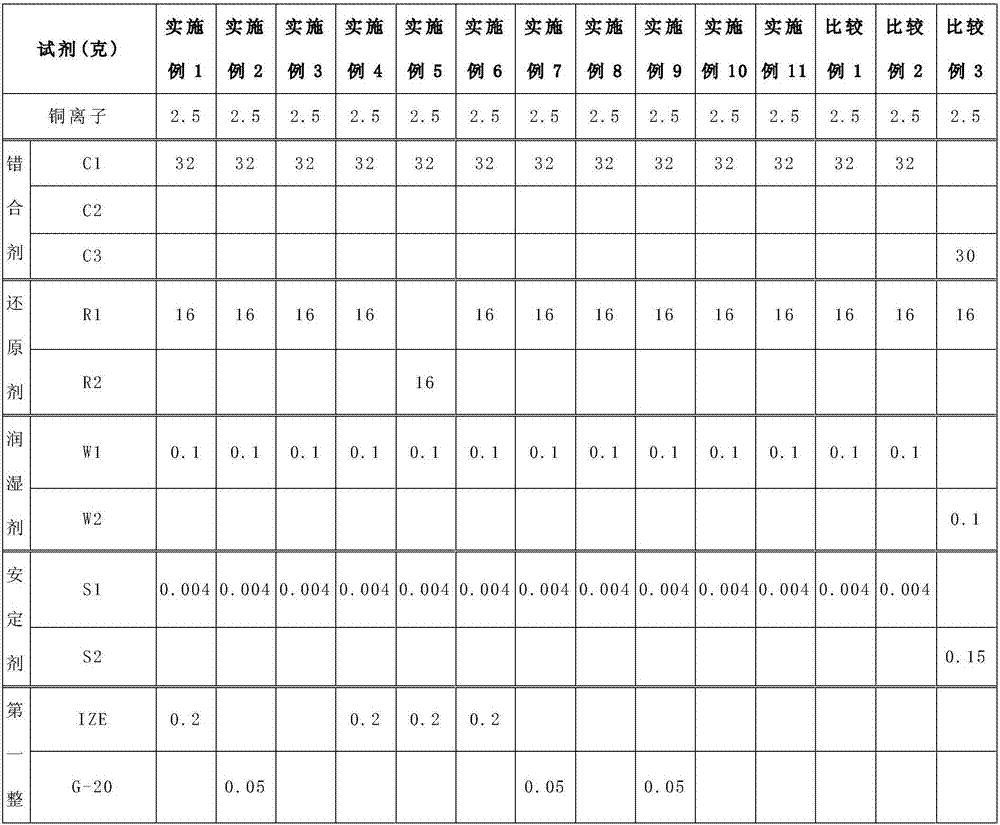

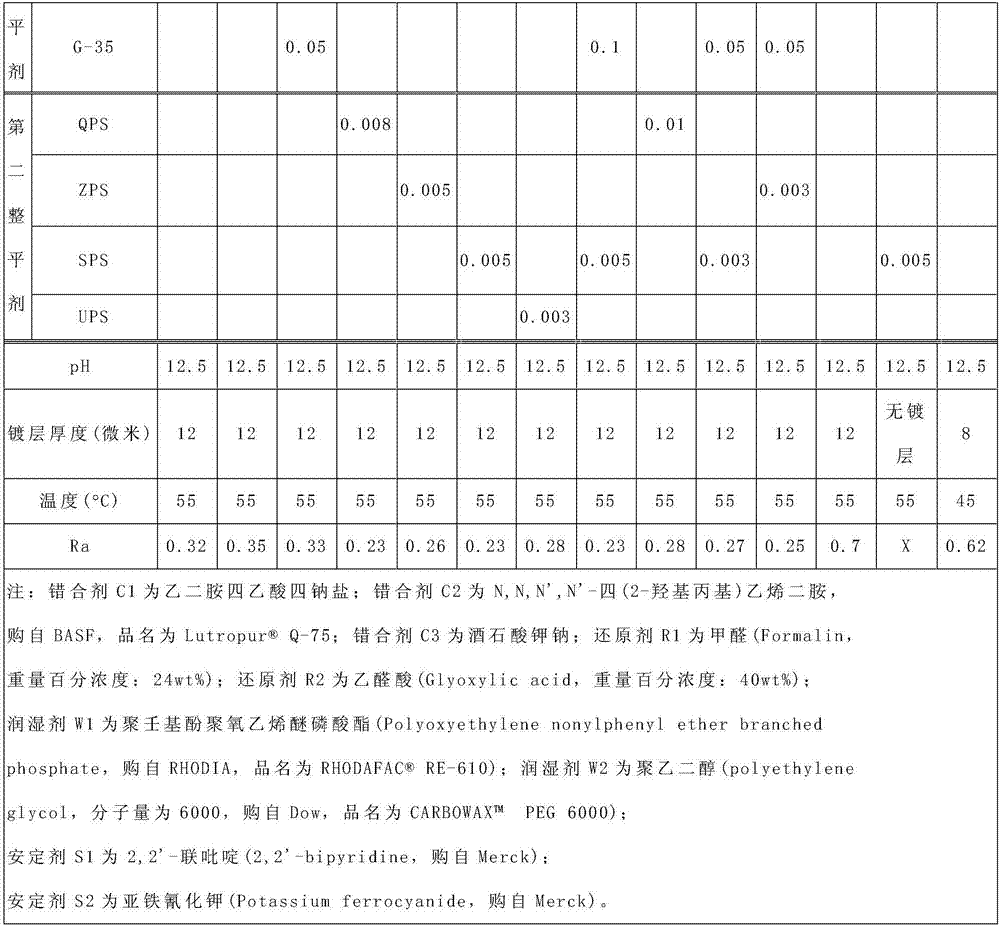

Examples

Embodiment 1

[0027] Plating solution preparation

[0028] Take 5.29g of copper chloride (ie: containing 2.5g of copper ions) into a 1L beaker, and add 0.5L of water, after dissolving, add ethylenediaminetetraacetic acid tetrasodium salt (EDTA-4Na) as a complexing agent , stirred until dissolved, and added sodium hydroxide (NaOH) to adjust the pH value to above 12.5, then heated to 55 ° C, then added 0.1 g of polynonylphenol polyoxyethylene ether phosphate (purchased from RHODIA, product name RE-610) as a wetting agent, and 0.004g of 2,2'-bipyridine (purchased from Merck) as a stabilizer, then, add 0.2g (ie: 200ppm) of imidazole / epichlorohydrin copolymer ( purchased from BASF under the name IZE, hereinafter referred to as IZE) as the first leveling agent, after it is dissolved, then add 16g of formaldehyde (Formalin) with a weight percent concentration of 24wt% as a reducing agent, and add water to the plating solution to make the overall volume 1L , and finally put the copper foil fo...

Embodiment 2 to 3

[0038] Referring to Table 1, this series of examples is roughly the same as Example 1, the main difference is that the first leveling agent used in the preparation of the plating solution is polyethyleneimine, with molecular weights of 1400 and 200, respectively. Polyethyleneimine with a molecular weight of 1400 is available from BASF under the name G 20 (hereinafter referred to as G-20), polyethyleneimine with a molecular weight of 200 is also purchased from BASF, the product name is G 35 (hereinafter referred to as G-35). The addition amount of said embodiment is all 0.05g (ie: 50ppm). The measured surface roughness Ra values are 0.35 and 0.33 respectively.

Embodiment 4

[0043] Referring to Table 1, this embodiment is substantially the same as Example 1, and the main difference is that when the plating solution is prepared, after adding the first leveler IZE, add 0.008g (i.e.: 8ppm) of quinaldine propanesulfonate benzyl (purchased from HOPAX, the product name is QPS) as the second leveler, and then continue to add reducing agent, replenish water to 1L and test plating operation. The plated copper produced by this plating solution has a surface roughness Ra value of 0.23 after testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com