Polyimide paint for low-viscosity enamelled wires, and preparation method and application of polyimide paint

A polyimide varnish and enameled wire technology, which is applied in coatings, electrical components, circuits, etc., can solve the problems of enameled wire production difficulties, low yield of enameled wires, and low solid content of lacquer liquid, so as to reduce coating difficulty and surface Low apparent viscosity and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

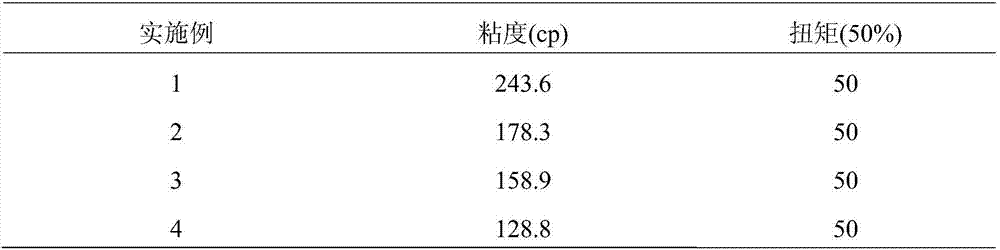

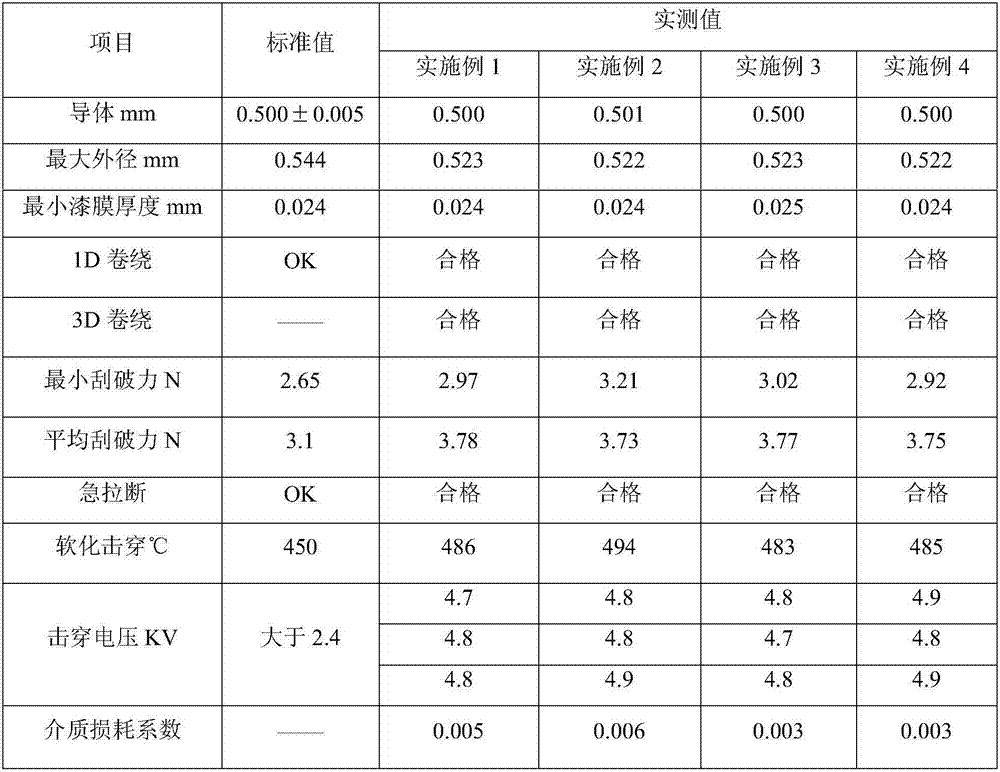

Embodiment 1

[0037] In a reactor equipped with a thermometer and mechanical stirring, under the condition of a constant temperature water bath at 20°C, dissolve 0.269mol of 4,4'-diaminodiphenyl ether in N,N-dimethylacetamide, and keep the temperature of the water bath at 20°C, followed by adding 0.00266mol of 5,10,15,20-tetrakis(4-aminobenzene)-21H,23H-porphyrin, stirring for 2 hours, and then adding 0.322mol of 3,3',4 , 4'-tetracarboxylic biphenyl dianhydride, react for 0.5 hours to obtain polyimide paint for low-viscosity enameled wire. Stir continuously during the whole process, and the solid content of the final solution is controlled at 15%.

Embodiment 2

[0039] In a reactor equipped with a thermometer and mechanical stirring, 0.1248mol of 4,4'-diaminodiphenyl ether and 0.0448mol of p-phenylenediamine were dissolved in N,N-dimethyl In formamide, keep the water bath temperature at 20°C, then add 0.0762mol of 5,10,15,20-tetrakis(4-aminobenzene)-21H,23H-porphyrin, stir for 2 hours, then add 0.161 mol of 3,3',4,4'-tetracarboxylic biphenyl dianhydride and 0.161 mol of 3,3',4,4'-tetracarboxylic benzophenone dianhydride, react for 1.5 hours to obtain low viscosity enameled wire Polyimide paint. Stir continuously during the whole process, and the solid content of the final solution is controlled at 15%.

Embodiment 3

[0041] In a reactor equipped with a thermometer and mechanical stirring, 0.138 mol of 4,4'-diaminodiphenyl ether and 0.100 mol of 2,2-bis[4-(3-aminobenzene Dissolve oxy)phenyl]propane in N-methylpyrrolidone, keep the temperature of the water bath at 20°C, then add 0.0042mol of 5,10,15,20-tetrakis(4-aminobenzene)-21H,23H-porphyrin morphine, stirred for 2 hours, then added 0.161mol of 3,3',4,4'-tetracarboxylic biphenyl dianhydride and 0.161mol of 3,3',4,4'-tetracarboxylic diphenyl ether diphenyl ether in 7 times anhydride, and react for 1 hour to obtain polyimide varnish for low-viscosity enameled wire. Stir continuously during the whole process, and the solid content of the final solution is controlled at 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com