Environment-friendly PP (polypropylene) foam floor board and method for preparing same

An environmentally friendly, floor technology, applied in chemical instruments and methods, building components, layered products, etc., can solve the problems of poor degradation performance, self-weight and other problems, and achieve the effect of low cost, light weight and easy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

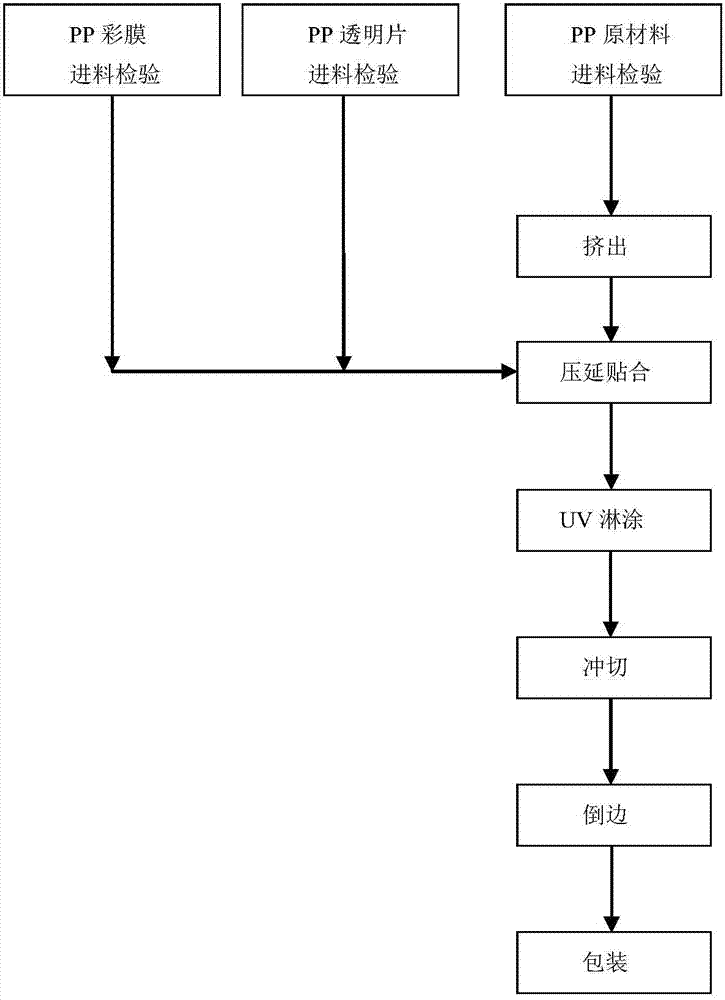

Method used

Image

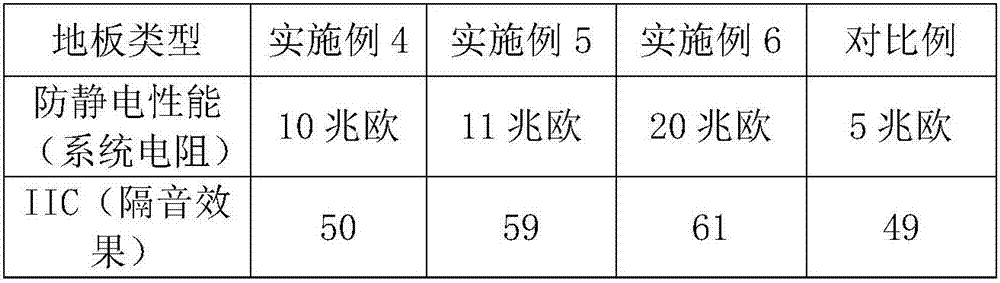

Examples

Embodiment 1

[0032] An environment-friendly PP foam floor, which is composed of three layers of PP color film, PP transparent sheet and composite PP foam bottom sheet. The specific composite PP foam bottom sheet includes the following preparation materials by weight: 60 parts of PP resin, 8 parts of mica, 20 parts of stone powder, 0.5 parts of solubilizer, 3 parts of epoxidized soybean oil, 0.5 part of antioxidant, and 0.5 part of lubricant; wherein, the solubilizer is specifically polysorbate; the antioxidant is specifically Antioxidant 1010; the lubricant is specifically calcium stearate, and the PP color film and PP transparent sheet are prepared by traditional techniques and formulas.

Embodiment 2

[0034] An environment-friendly PP foam floor, which is composed of three layers of PP color film, PP transparent sheet and composite PP foam bottom sheet. The specific composite PP foam bottom sheet includes the following preparation materials by weight: 70 parts of PP resin, 10 parts of mica, 35 parts of stone powder, 1 part of solubilizer, 9 parts of epoxidized soybean oil, 1 part of antioxidant, and 1 part of lubricant; wherein, the solubilizer is specifically polysorbate; the antioxidant is specifically Antioxidant 1010; the lubricant is specifically calcium stearate, and the PP color film and PP transparent sheet are prepared by traditional techniques and formulas.

Embodiment 3

[0036] An environment-friendly PP foam floor, which is composed of three layers of materials: PP color film, PP transparent sheet and composite PP foam bottom sheet. The specific composite PP foam bottom sheet includes the following preparation materials by weight: 65 parts of PP resin, 7 parts of mica, 25 parts of stone powder, 0.6 parts of solubilizer, 5 parts of epoxidized soybean oil, 0.6 part of antioxidant, and 0.8 part of lubricant; wherein, the solubilizer is specifically polysorbate; the antioxidant is specifically Antioxidant 1010; the lubricant is specifically calcium stearate, and the PP color film and PP transparent sheet are prepared by traditional techniques and formulas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com