Amphoteric heat-resistant and salt-resistant filtrate reducer for drilling fluid and preparation method

A technology of fluid loss reducer and drilling fluid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as fluid loss, achieve the effects of low residue, low raw material cost, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

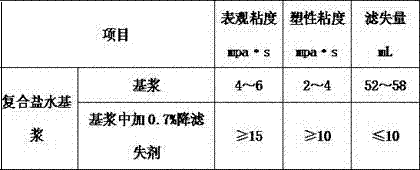

Image

Examples

Embodiment 1

[0032] The parts by weight of raw materials are: acrylamide 280, 2-acrylamide-2-methylpropanesulfonic acid 56, acrylic acid 28, dimethyl diallyl ammonium chloride 42, N-vinylpyrrolidone 14, deionized water 546, Sodium hydroxide 10.55, potassium hydroxide 22.14, lauryl betaine 1.5, azobisisobutyronitrile 0.3, potassium persulfate 0.012, sodium bisulfite 0.008.

[0033] The specific preparation process is:

[0034] (1) Add acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, acrylic acid, dimethyl diallyl ammonium chloride, N-vinylpyrrolidone and deionized water in sequence in the mixing tank, fully After dissolving, neutralize acrylic acid and 2-acrylamide-2-methylpropanesulfonic acid with sodium hydroxide or potassium hydroxide, and adjust the pH value of the solution to 7.5-7.7, then add dodecane base betaine, mixed well;

[0035] (2) Deoxygenate with nitrogen for 60 minutes, add an initiator and polymerize at 14~16°C;

[0036] (3) After the reaction is over, take out th...

Embodiment 2

[0039] The parts by weight of raw materials are: acrylamide 300, 2-acrylamide-2-methylpropanesulfonic acid 60, acrylic acid 32, dimethyl diallyl ammonium chloride 45, N-benzyl-3-pyrrolidone 15, deionized Water 511, sodium hydroxide 11.7, potassium hydroxide 24.66, dodecyl betaine 1, azobisisobutyronitrile 0.5, potassium persulfate 0.02, sodium bisulfite 0.01.

[0040] The specific preparation process is:

[0041] (1) Add acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, acrylic acid, dimethyl diallyl ammonium chloride, N-benzyl-3-pyrrolidone, deionized Water, after fully dissolving, neutralize acrylic acid and 2-acrylamide-2-methylpropanesulfonic acid with sodium hydroxide or potassium hydroxide, and adjust the pH value of the solution to 7.5~7.7, then add Lauryl Betaine, mix well.

[0042](2) Deoxygenate with nitrogen for 60 minutes, add an initiator and polymerize at 14~16°C;

[0043] (3) After the reaction is over, take out the jelly, granulate the rubber block, and...

Embodiment 3

[0046] The parts by weight of raw materials are: 330 parts by weight of acrylamide, 66 parts of 2-acrylamide-2-methyl propane sulfonic acid, 0.5 parts of sodium methacrylate, 35 parts of acrylic acid, 49.5 parts of dimethyl diallyl ammonium chloride, and 49.5 parts of N-vinyl Pyrrolidone 16.5, deionized water 462, sodium hydroxide 12.87, potassium hydroxide 27.03, lauryl amidopropyl betaine 1.5, azobisisobutyronitrile 0.4, potassium persulfate 0.035, sodium bisulfite 0.015.

[0047] The specific preparation process is:

[0048] (1) Add acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, sodium methacrylsulfonate, acrylic acid, dimethyl diallyl ammonium chloride, N-vinyl Pyrrolidone, deionized water, fully dissolved, neutralize acrylic acid and 2-acrylamide-2-methylpropanesulfonic acid with sodium hydroxide or potassium hydroxide, and adjust the pH value of the solution to a value between 7.5 and 7.7 In the meantime, add lauryl amidopropyl betaine and mix thoroughly.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com