Deformable stimuli responsive material and preparation method thereof and stimuli responsive flexible microelectrode array

A stimuli-responsive and thermal-responsive technology, applied in the field of biomedical engineering, can solve the problems of delamination between the responsive layer and the flexible substrate, high trigger temperature, and limitations in practical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A deformable stimuli-responsive material, which is composed of a heat-responsive material, the heat-responsive material is polyisopropylacrylamide, the deformable stimuli-responsive material has a local Young's modulus difference, and the local Young's modulus The difference is brought about by the difference in cross-linking degree of the region. The deformable stimulus-responsive material is a thermoresponsive hydrogel with a thickness of 1mm.

[0070] The preparation method of the deformable stimulus response material comprises the following steps:

[0071] (1) Dissolve 0.9156g of isopropylacrylamide and 97mg of methylene bisacrylamide in 10mL of water and mix well, then add 125μL of photoinitiator diethoxyacetophenone, and the prepolymer solution is obtained after the solution is mixed evenly ;

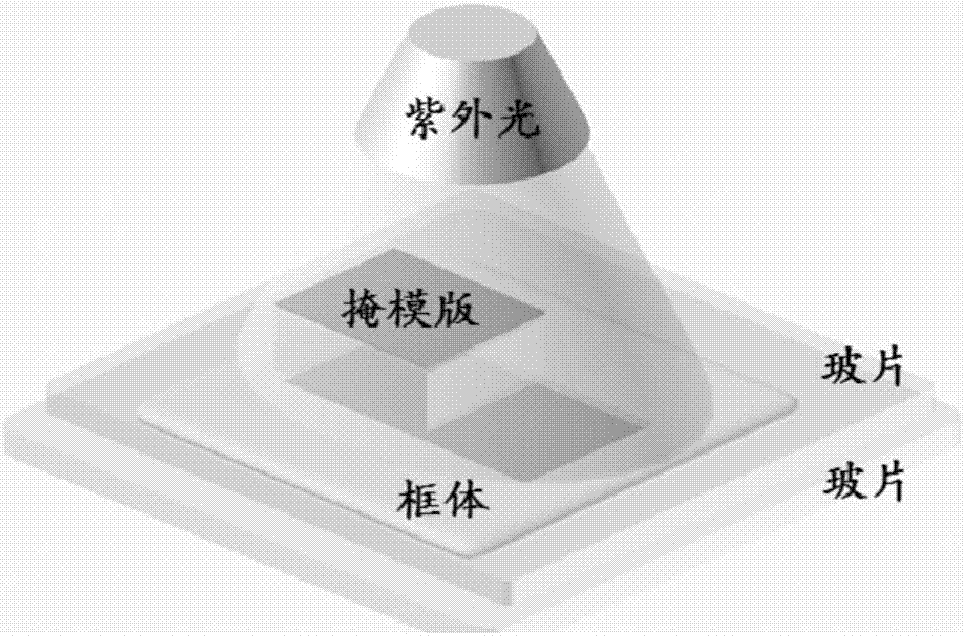

[0072] (2) if figure 1 As shown, the pre-poly solution is injected into the mold, and the mold is composed of two pieces of glass and a polytetrafluoroethylene frame with...

Embodiment 2

[0075] A deformable stimuli-responsive material, which is composed of photothermal responsive materials composed of two groups of A and B. Part of the deformable stimuli-responsive material is composed of photothermal responsive materials composed of group A, and part of the region is composed of photothermal responsive materials composed of group B. The composition of the photothermoresponsive material, specifically, the composition of group A includes thermosensitive polymers (specifically polyisopropylacrylamide and poly(N-ethylacrylamide)) and photothermal nanoparticles (specifically gold nanorods ), group B consists of thermosensitive polymers (specifically poly(N-ethylacrylamide)) and photothermal nanoparticles (specifically gold nanorods), in the composition of A and B groups, the photothermal nano The weight percent content of the particles is 5%, and the deformable stimulus-responsive material has a local difference in Young's modulus, and the difference in local Young...

Embodiment 3

[0082] A deformable stimuli-responsive material specifically includes a temperature-sensitive polymer (specifically polyisopropylacrylamide) and magnetocaloric nanoparticles (specifically ferric oxide), and the content of the magnetocaloric nanoparticles is 5% by weight. %, the deformable stimuli-responsive material has a local difference in Young's modulus, the local Young's modulus difference is brought about by the alignment of ferric oxide nanoparticles, and the deformable stimuli-responsive material has a thickness of 500 μm Magnetothermal responsive hydrogels.

[0083] The preparation of the deformable stimuli-responsive material is regulated by an external magnetic field, so that the rigid iron ferric oxide nanoparticles are oriented along the long axis in the pre-polymerization solution of isopropylacrylamide, and then a composite gel is formed by irradiation polymerization , the directional arrangement of rigid iron ferric oxide in the flexible hydrogel material bring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com