Chemical-erosion-resisting, high-strength and high-toughness concrete and preparation method thereof

A technology of concrete and high toughness, applied in the field of building materials, can solve the problems of unfavorable chemical corrosion resistance of concrete, and achieve the effect of solving poor compatibility, improving ability and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

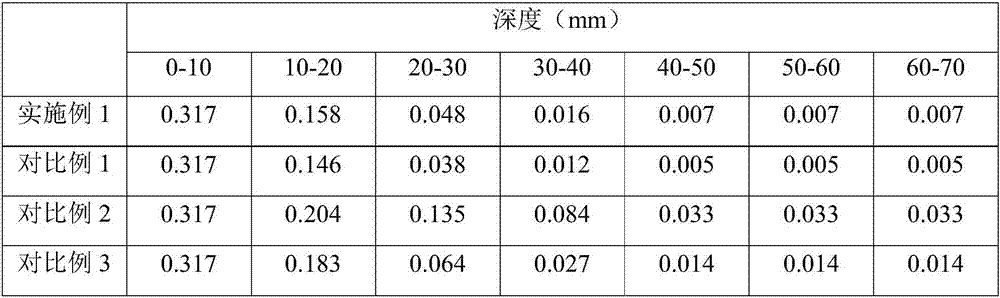

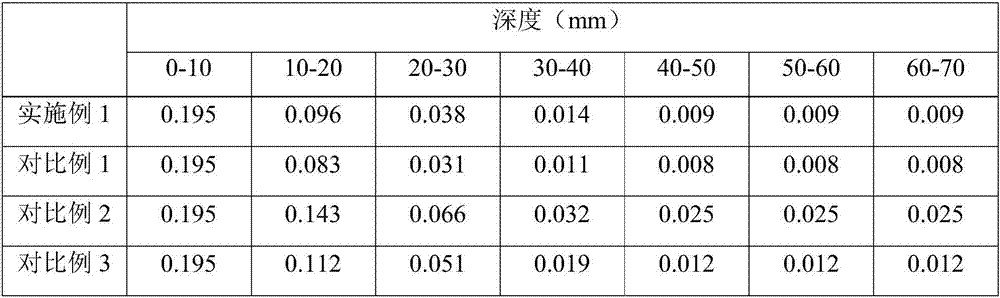

Examples

preparation example Construction

[0031] 2. Preparation of MCN-LDHs composites

[0032] MCN-LDHs composites were prepared by solid-state pyrolysis reaction. Weigh a certain amount of the CoFeMgAl-TA-LDHs precursor synthesized in the first step of the experiment, and spread it evenly in the porcelain boat, and place the porcelain boat in the heat preservation area of the tubular atmosphere furnace. First, the air in the tube furnace is evacuated by a vacuum pump, and then the N 2 Pass into the tube-type atmosphere furnace until the inside of the tube is at an atmospheric pressure, and then set the temperature rise and control program to make the sample rise to the target temperature at a rate of 5°C / min, and keep feeding N 2 Atmosphere and make the cross-sectional flow of air flow 60ml / cm 2 ·min, start the heating process to make the reaction carbonization temperature reach 823K-1173K (550-900°C), and the time is 2h.

[0033] 3. Preparation of high-strength and high-toughness concrete resistant to chemical...

Embodiment 1

[0038] After the composite functional material is prepared, the method comprising the following steps is used to obtain the chemical erosion-resistant high-strength and high-toughness concrete. Among them, the specific ratio of concrete is selected from the median value of each component.

[0039] 1) Add the MCN-LDHs composite material into the polyacrylate emulsion and stir for 15 minutes to obtain the stirring material A.

[0040] 2) Add the water reducing agent into the water and stir for 30 minutes to obtain the mixing material B.

[0041] 3) After putting the fine aggregate and crushed stone into the concrete mixer and stirring for 15 minutes, slowly pour the polyacrylate emulsion containing MCN-LDHs composite material (mixing material A) into the mixer within 5 minutes, and continue stirring for 10 minutes after pouring, Mixture C is obtained.

[0042] 4) Pour the cement and slag powder into the mixing material C, and after stirring for 15 minutes, the mixing material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com