Automatic polishing and grinding machine for seal stones

A seal and stone grinding technology, applied in the field of automatic seal stone grinding and polishing machines, can solve the problems of cracked seal stone and the inability of mechanized and efficient processing of seal stone workpieces, and achieves improved processing efficiency, high flatness, and good processing surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

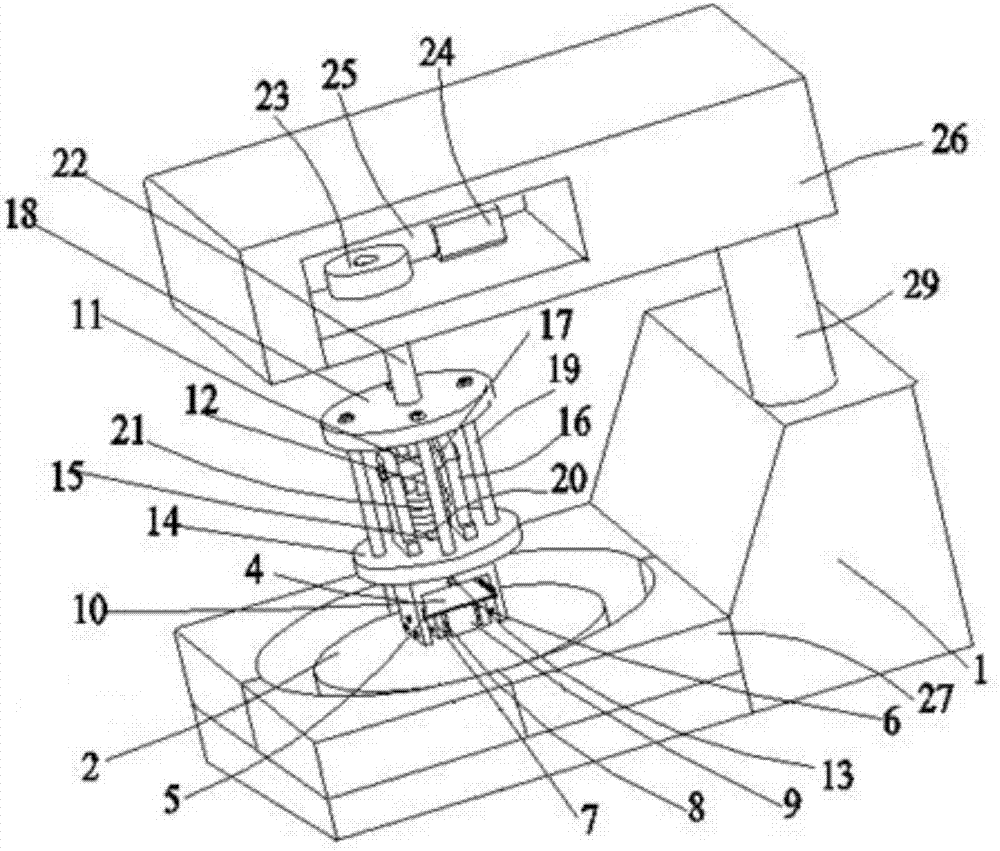

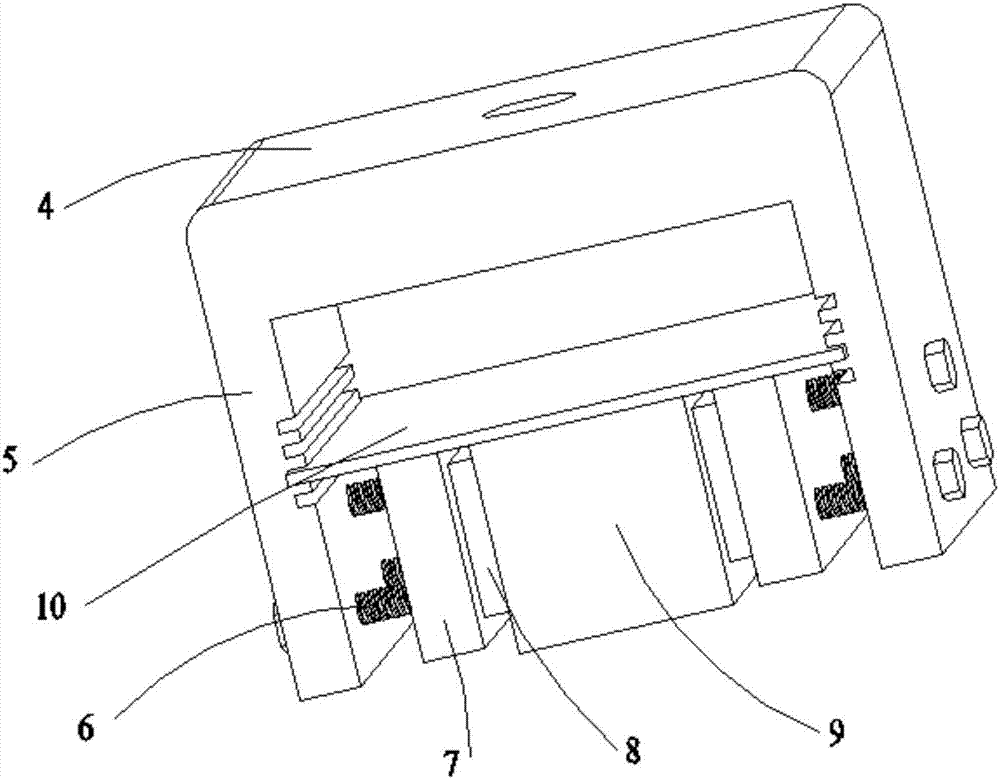

[0024] Examples, see Figure 1-Figure 4 As shown, an automatic seal stone grinding and polishing machine of the present invention includes a frame, a tray table 2, a main motor (not shown in the figure), a clamping mechanism 4, an auxiliary motor 24, a transmission mechanism 11, and a polishing liquid injection device (not shown in the figure), main motor, auxiliary motor 24 are installed on the frame respectively, and the grinding and polishing pad is arranged on the carrier table 2, and is driven to rotate by main motor; , to drive the clamping mechanism 4 to rotate around its axis; the clamping mechanism 4 is located on the main motor, and the clamping mechanism 4 pushes the clamped seal stone workpiece against the surface of the grinding and polishing pad through a push-off mechanism; the polishing liquid The spraying device is installed on the frame, and its nozzles point to the disc loading table.

[0025] In this embodiment, the disk carrier 2 is specifically installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com