A laser land leveling system

A laser system and land technology, applied in the fields of land preparation machinery, agriculture, application, etc., can solve the problems of unfavorable land fine leveling operations, inability to adjust the height of the left and right ends, and easy to shovel out slopes, etc. Passability and stability, the effect of reducing technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

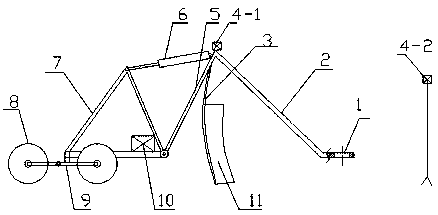

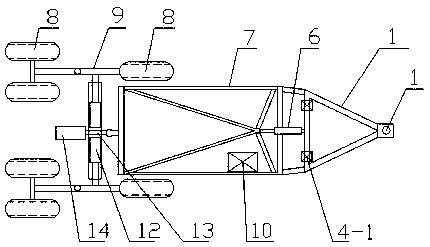

[0017] A laser land leveling system, including a frame 5, a laser system 4 and a computer control system 10, the laser system includes two sets of laser transmitters 4-1 and a laser receiver 4 matching the two sets of laser transmitters -2, the two groups of laser transmitters are fixedly installed on the left and right sides of the frame respectively, and the laser receiver is fixedly installed on the reference point of the land; the lower end of the frame 5 is fixedly installed with leveling The front end of the shovel 3 and the frame 5 is fixedly connected to the connecting rod 2, and the end of the connecting rod 2 is provided with a pin hole 1 for connecting the driving device, and the rear end of the frame 5 is hinged with a triangular truss 7, and the triangular truss 7 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com