Method for measuring corrosion resistance of cutting fluid

A cutting fluid and anti-corrosion technology, applied in the preparation of test samples, weather resistance/light resistance/corrosion resistance, measuring devices, etc., to achieve fast and accurate measurement results, accurate test results, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0029] Analysis and determination method - fully synthetic water-based cutting fluid;

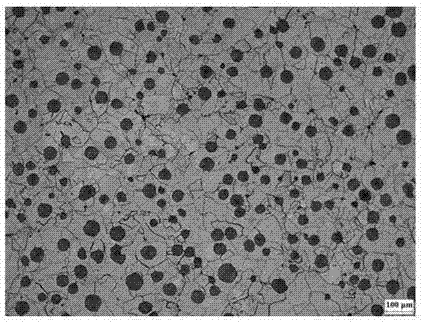

[0030](1) Production of working electrode: QT400-18 ductile iron sample is processed into a cube of 10mm×10mm×10mm as the working electrode. After cold mounting, the five surfaces are isolated from the solution, and only one surface is left in contact with the solution as the electrochemical corrosion working surface. This surface is wet-ground with SiC sandpaper, and the sandpaper is finally as fine as 1500#, then cleaned with distilled water, and air-dried with a hair dryer.

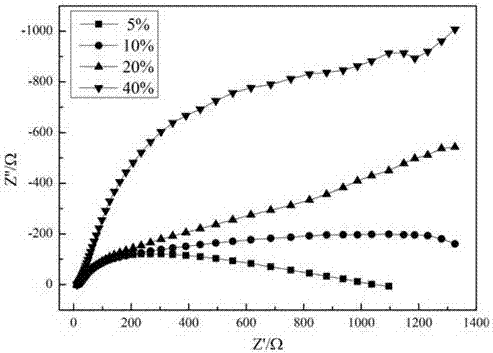

[0031] (2) Corrosive medium solution preparation: configure one of the 3.5% NaCl solution corrosive medium, according to the ratio of 5%, 10%, 20%, 40%, measure 10ml, 20ml, 40ml, 80ml cutting fluid with a measuring cylinder respectively, and stir Slowly add to the prepared 200ml NaCl solution, and the final mixed solution is used as the electrochemical corrosion medium.

specific Embodiment 2

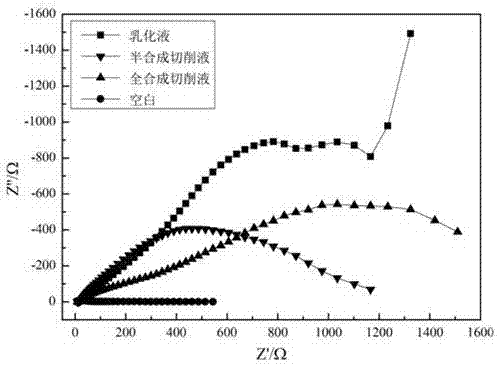

[0040] Analysis and determination method - semi-synthetic cutting fluid 40ml;

[0041] (1) Production of working electrode: QT400-18 ductile iron sample is processed into a cube of 10mm×10mm×10mm as the working electrode. After cold mounting, the five surfaces are isolated from the solution, and only one surface is left in contact with the solution as the electrochemical corrosion working surface. This surface is wet-ground with SiC sandpaper, and the sandpaper is finally as fine as 1500#, then cleaned with distilled water, and air-dried with a hair dryer.

[0042] (2) Corrosion medium solution preparation: configure one of the 3.5% NaCl solution corrosion medium, according to the optimal ratio of 20%, measure 40ml of fully synthetic water-based cutting fluid with a graduated cylinder, and slowly add it to the prepared 200ml NaCl solution while stirring , and the final mixed solution is used as an electrochemical corrosion medium.

[0043] (3) Three-electrode system construct...

specific Embodiment 4

[0056] Analysis and determination method, the reproducibility of the determination of the polarization resistance Rp of the emulsified cutting fluid;

[0057] (1) the making of working electrode is with the step (1) of embodiment one;

[0058] (2) Corrosion medium solution preparation: configure one of the 3.5% NaCl solution corrosion medium, according to the optimal ratio of 20%, measure 40ml emulsified cutting fluid with a measuring cylinder, and slowly add it to the prepared 200ml NaCl solution while stirring, and finally get The mixed solution is used as the electrochemical corrosion medium.

[0059] (3) The three-electrode system is set up with the step (3) of Embodiment 1;

[0060] (4) The setting of electrochemical workstation working conditions and working parameters is the same as the step (4) of embodiment one;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com