Pipe fitting with double metallic composite elbows

An elbow pipe and bimetal technology, applied in the direction of elbows, pipes/pipe joints/fittings, pipe components, etc., can solve the problems of loose connection and high manufacturing cost, achieve small flow resistance, ensure firmness and stability, Fluency effect of substances such as acid and alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

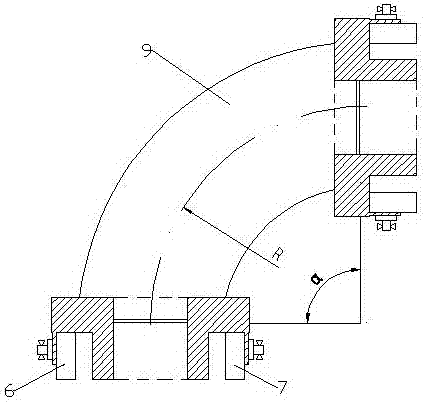

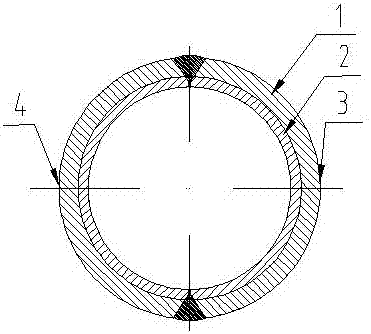

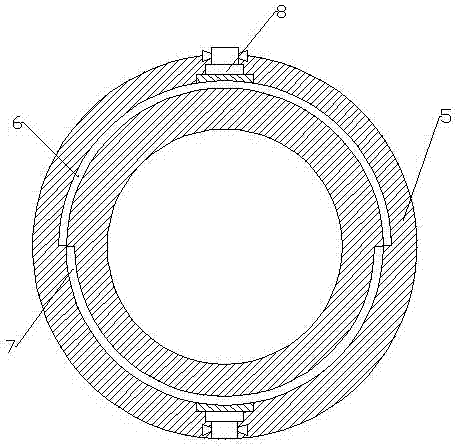

[0023] A bimetal composite elbow pipe fitting, characterized in that it includes an outer layer 1, an inner layer 2, a fixing device, and a pipe fitting 9; the outer layer 1 includes a first half-shell elbow 3 and a second half-shell elbow 4 , the first half-shell elbow 3 and the second half-shell elbow 4 are fixedly connected to the inner layer 2, and the fixing device includes a fixed body 5, a first fixed shell 6, a second fixed shell 7, a rotating Bolt 8; the fixed body 5 is a T-shaped structure with a cylindrical hole in the middle, the first fixed shell 6 and the second fixed shell 7 are respectively located on both sides of the lower end of the T-shaped, and can be placed on the fixed body 5 Move in the radial direction of the fixed body 5, the outer circumference of the fixed body 5 is provided with bosses, and the rotating bolts 8 are respectively connected with the first fixed shell 6 and the second fixed shell 7 through the bosses of the fixed body 5, so that The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com