A pump casing of a screw vacuum pump

A technology for screw vacuum pumps and pump casings, which is applied to parts of pumping devices for elastic fluids, rotary piston type/oscillating piston type pump parts, pump elements, etc., and can solve the problem of poor fluidity of anti-corrosion metals and anti-corrosion of cast iron Poor performance, one-time access to the pump casing and other problems, to achieve the effect of improving corrosion resistance, eliminating maintenance, and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

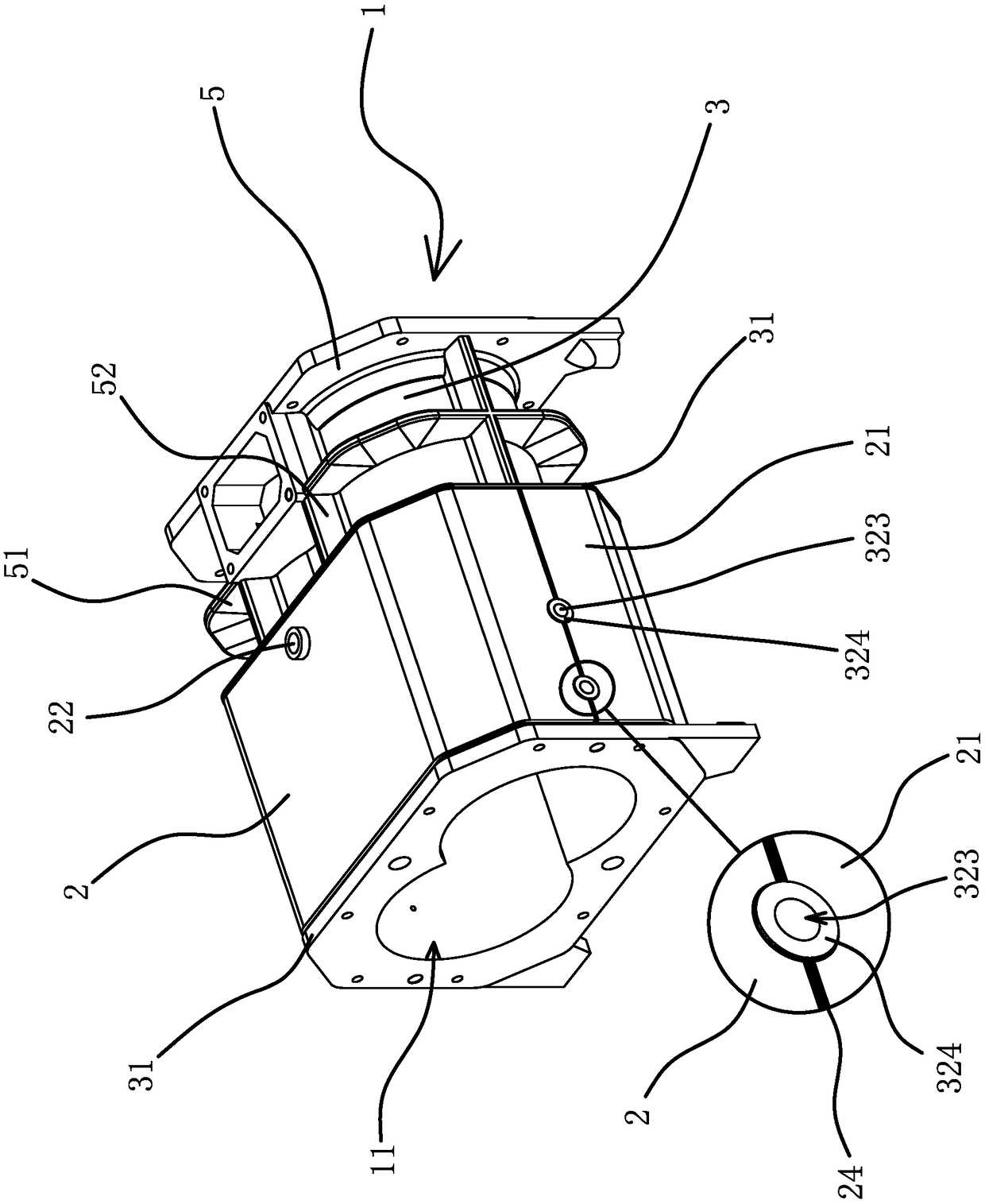

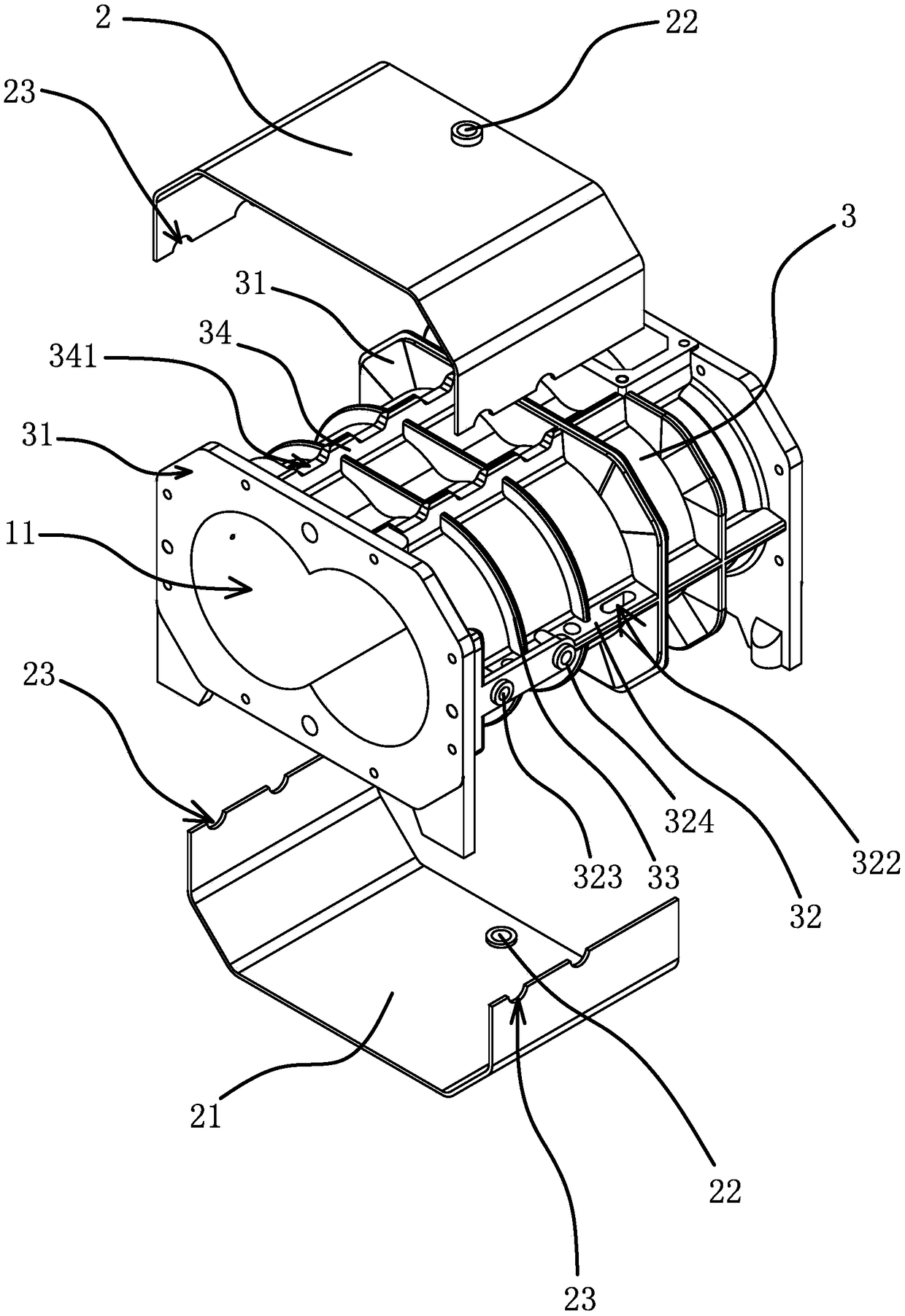

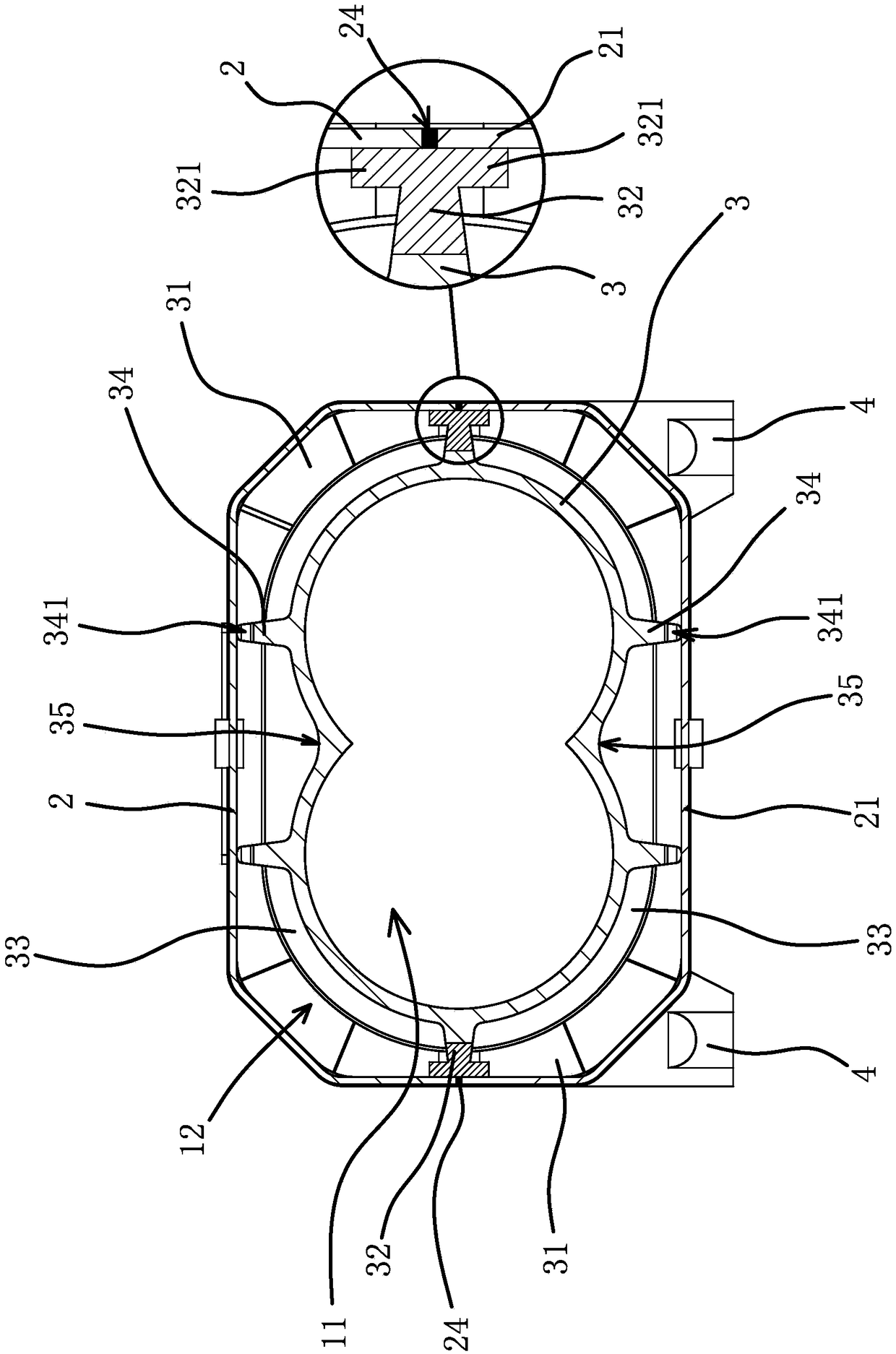

[0026] Such as Figure 1 to Figure 4 As shown, the pump casing of the screw vacuum pump includes a pump body 1 with a pump chamber 11, and a cooling water chamber 12 inside the pump body 1. The pump body 1 is composed of several outer casings 6 and an inner casing 3 made of anti-corrosion metal. In this embodiment, the outer casing 6 includes an outer casing one 2 and an outer casing two 21, and the inner casing 3 has the above-mentioned pump chamber 11. Specifically, the inner casing 3 can be made of stainless steel or titanium alloy or Monel alloy or Hastelloy. Alloy precision casting.

[0027] Such as Figure 2 to Figure 5 As mentioned above, the inner housing 3 has two annular fixing ribs 31 along the length directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com