A kind of production method of sesame-flavored pit mud

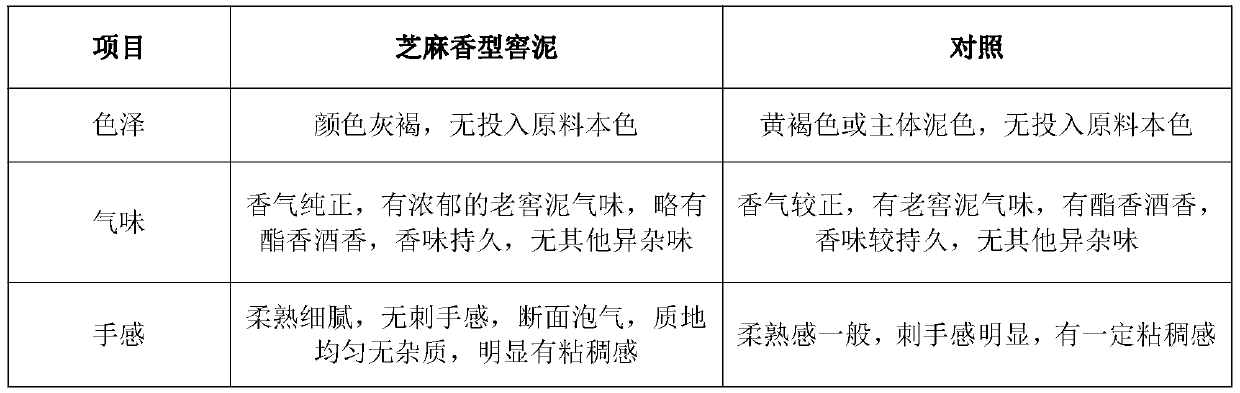

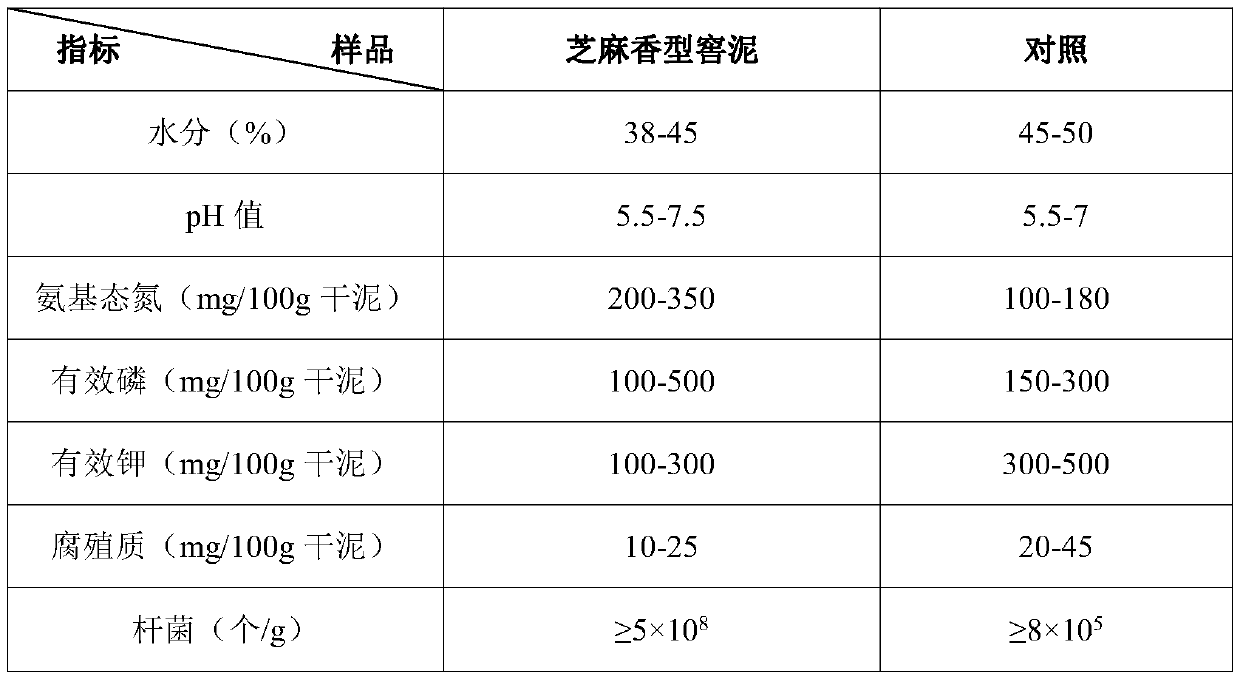

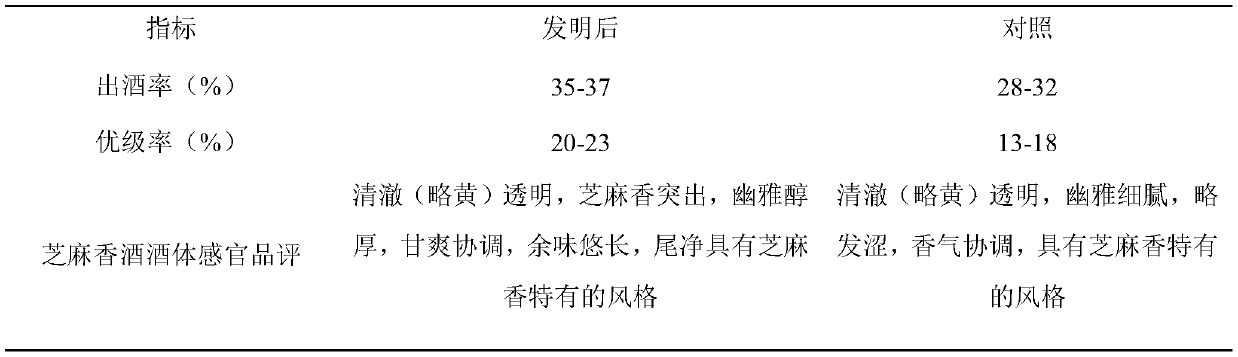

A technology of sesame-flavor type and production method, which is applied in the field of wine making, can solve the problems affecting the production of sesame-flavor liquor, high-grade rate, liquor yield, and lack of aroma of pit mud ester, so as to enrich flavor substances and precursor substances, The texture has no impurities and the effect of uniform texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the following steps produce sesame-flavored pit mud

[0027] (1) The mixing ratio is: in terms of parts by mass, take 30 parts of loess, 20 parts of lotus root pond sludge, 3.5 parts of old pit mud, 20 parts of fresh waste, 5 parts of soybean meal powder, 0.5 part of pea powder, bone meal 0.5 parts, 2 parts of bottom pot water, 3 parts of yellow water, 15 parts of low-alcohol tailings, mixed and moistened;

[0028] (2) the preparation of cellar mud fermented liquid comprises the following steps:

[0029] a) Preparation of seed liquid: the mixed cellar mud and distilled water made by the ratio of 1:2 (by mass) of Luzhou-flavor cellar cell wall cellar cellar and bottom cellar cellar mud (by mass) Mix at a mass ratio of 1:10, keep in a water bath at 80°C for 30 minutes, and make functional bacteria seed liquid;

[0030] b) Preparation of functional strain expansion medium: take 1% soybean powder, 3% peptone, 0.3% yeast extract, 0.8% ammonium phosphate, 0.4%...

Embodiment 2

[0044] Embodiment 2: the following steps produce sesame-flavored pit mud

[0045] (1) The mixing ratio is: in terms of parts by mass, take 40 parts of loess, 20 parts of lotus root pond sludge, 3 parts of old pit mud, 12 parts of fresh waste, 5 parts of soybean meal powder, 0.6 part of pea powder, bone meal 0.5 parts, 2 parts of bottom pot water, 3 parts of yellow water, 10 parts of low-alcohol tailings, mixed and moistened;

[0046] (2) the preparation of cellar mud fermented liquid comprises the following steps:

[0047] a) Preparation of functional bacteria seed liquid: the mixed cellar mud and Distilled water was mixed at a mass ratio of 1:15, kept in a water bath at 85°C for 20 minutes, and then made into a functional bacteria seed solution;

[0048] b) Preparation of functional strain expansion medium: take 3% soybean powder, 1% peptone, 0.1% yeast extract, 1.2% ammonium phosphate, 0.6% magnesium sulfate and the rest of yellow water according to the mass ratio, and the...

Embodiment 3

[0062] Embodiment 3: the following steps produce sesame-flavored pit mud

[0063] (1) The mixing ratio is: according to the mass ratio, take 35 parts of loess, 30 parts of lotus root pond sludge, 5 parts of old pit mud, 10 parts of fresh waste, 10 parts of soybean meal powder, 1 part of pea powder, 0.2 parts of bone meal, 3 parts of bottom pot water, 5 parts of yellow water, and 15 parts of low-alcohol tailings are mixed and moistened;

[0064] (2) the preparation of cellar mud fermented liquid comprises the following steps:

[0065] a) Preparation of functional bacteria seed liquid: the mixed cellar mud and Distilled water was mixed at a mass ratio of 1:20, kept in a water bath at 80°C-85°C for 25 minutes, and then made into a functional bacteria seed solution;

[0066] b) Preparation of functional strain expansion medium: take 2% bean paste powder, 3% peptone, 0.3% yeast extract, 1.0% ammonium phosphate, 0.5% magnesium sulfate and the rest of yellow water according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com