Christmas tree oil-resistant sealing grease composition and preparation method thereof

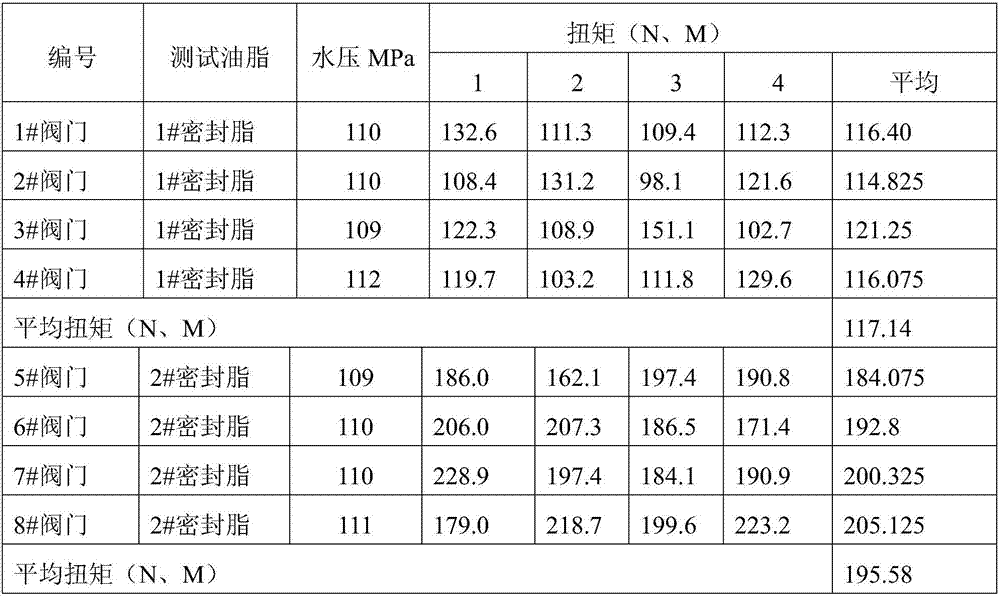

A technology of sealing grease and christmas tree, which is applied in the field of sealing grease, which can solve the problems of insufficient high temperature performance, dissolution, flushing, and difficult opening of valves, and achieve good colloidal stability and water resistance, and is not easy to squeeze or flush The effect of loss, opening torque drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

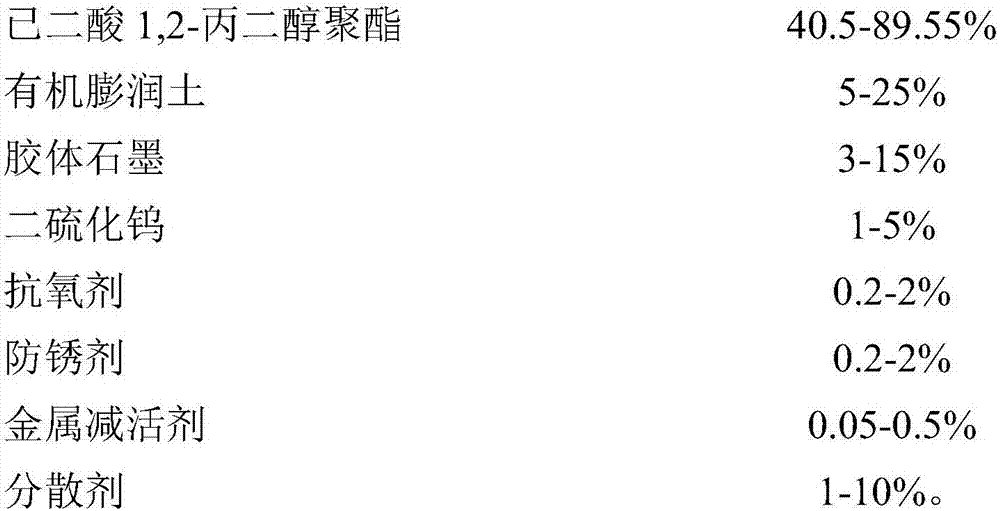

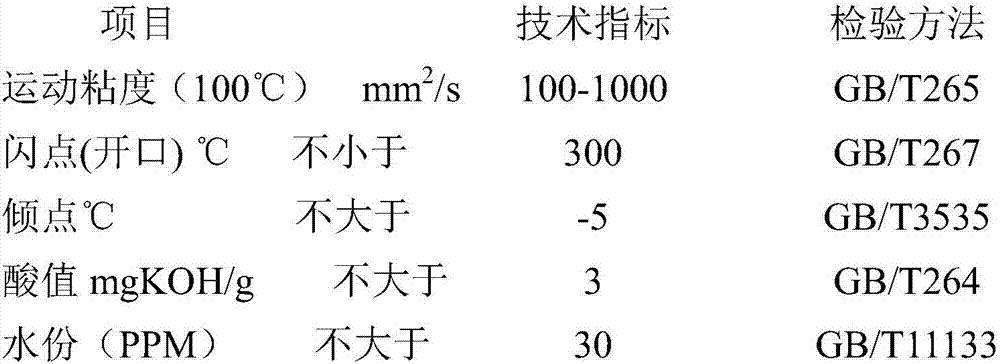

Method used

Image

Examples

Embodiment 1

[0066] 1) 725.5 kilograms of adipic acid 1,2-propylene glycol polyester (V 100 =395.48mm 2 / s) and 145 kg of organic bentonite are added to the reaction kettle, heated and stirred to raise the temperature to 60±5°C, add 35 kg of 95% industrial ethanol, stir at a constant temperature of 60±5°C for 15 minutes, continue to stir and raise the temperature to 130±5°C , evacuate to -0.05mpa, keep constant temperature and constant vacuum for dealcoholization and dehydration for 1.5 hours.

[0067] 2) Add 50 kg of colloidal graphite, 30 kg of tungsten disulfide, 5 kg of 4.4 methyl bisphenol, 7.5 kg of medium-alkali value synthetic calcium sulfonate, and 2 kg of benzotriazole in sequence, and mix and stir for 30±5 minutes. Discharge into barrel.

[0068] 3) Naturally cool to 60±5°C, and grind three times with a three-roll mill to obtain christmas tree oil-resistant sealant.

Embodiment 2

[0070] 1) 640.5 kilograms of adipic acid 1,2-propylene glycol polyester (V 100 =461.73mm 2 / s) and 160 kg of organic bentonite were added to the reaction kettle, heated and stirred to 60±5°C, added 45 kg of 95% methanol, stirred at 60±5°C for 15±5 minutes, and continued to stir to raise the temperature to 130±5°C 5°C, vacuumize to -0.05mpa, keep constant temperature, constant temperature and constant vacuum for dealcoholization and dehydration for 1.5 hours.

[0071] 2) Add 100 kg of colloidal graphite, 30 kg of tungsten disulfide, 10 kg of synthetic calcium sulfonate with medium alkali value, 5 kg of synthetic calcium sulfonate with high alkali value, 2.5 kg of 2,6 di-tert-butyl-p-cresol and 5 kg of N-phenyl-α-aniline and 2 kg of benzotriazole were mixed and stirred for 30±5 minutes, and discharged into the bucket.

[0072] 3) Naturally cool to 60±5°C, and grind three times with a three-roller mill to obtain christmas tree oil-resistant sealant.

Embodiment 3

[0074] 1) 699 kilograms of adipic acid 1,2-propylene glycol polyester (V 100 =692.21mm 2 / s) and 150 kg of organic bentonite were added to the reaction kettle, heated and stirred to 60±5°C, 37.5 kg of 96.6% acetone was added, stirred at 60±5°C for 15±5 minutes, and the temperature was raised to 130±5 ℃, vacuum to -0.05mpa, keep constant temperature and constant vacuum to remove acetone and dehydration for 1.5 hours.

[0075] 2) Add 50 kilograms of colloidal graphite, 50 kilograms of tungsten disulfide, 7.5 kilograms of 2,6-di-tert-butyl p-formic acid, 5 kilograms of high base value synthetic calcium sulfonate and 1 kilogram of benzotrihydroazole derivatives and mix and stir for 30 ±5 minutes, the material is discharged into the bucket.

[0076] 3) Naturally cool to 60±5°C, and grind three times with a three-roll mill to obtain christmas tree oil-resistant sealant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com