Formula of coating solution and preparation method and application of coating solution

A technology of coating liquid and graphene, which is applied in the formulation and preparation of coating liquid, can solve problems such as non-conforming color fastness to rubbing, affecting product service life, poor flatness, etc., and achieves excellent color fastness to rubbing, excellent Wear-resistant and scratch-resistant, excellent water vapor absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

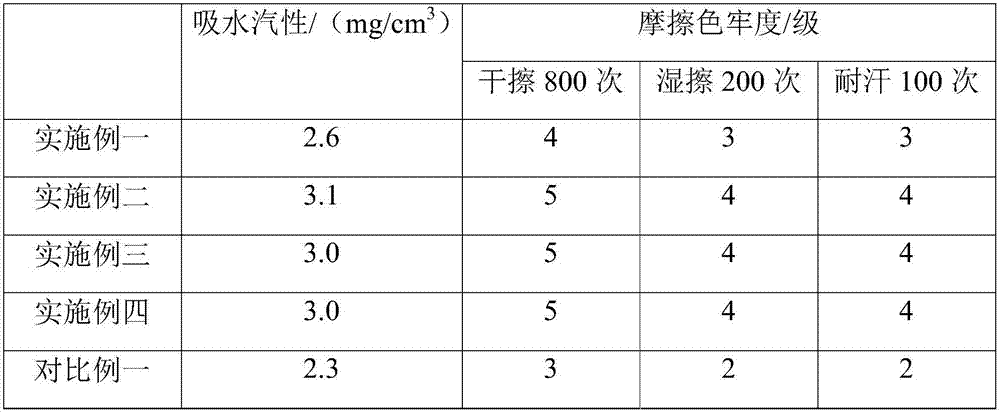

Examples

preparation example Construction

[0031] A kind of preparation method of coating liquid of the present invention comprises the following steps:

[0032] S101: Soak graphene in acid solution, and heat at 110°C-130°C for 3h-5h; wherein, in the acid solution, the solutes are sulfuric acid and phosphoric acid, and the weight ratio of sulfuric acid and phosphoric acid is 1:(0.5-0.8 ).

[0033] S102: Add remaining raw material components to the product obtained in S101 and stir evenly to prepare a coating liquid. Wherein, the stirring conditions are specifically: the temperature is 65°C-75°C, the rotation speed is 2500rpm-3500rpm, and the time is 3h-6h.

[0034] For the coating liquid prepared by the present invention, the present invention specially designs the application method of the coating liquid, so as to apply it to leather products, especially leather mats. Specifically: apply the coating solution to the leather base cloth; wherein, the leather base cloth includes one or more of knitted fabrics, woven fab...

Embodiment 1

[0037]The invention provides a kind of coating liquid, comprises following raw material components: graphene, polyurethane resin and water; Wherein, the mass ratio of graphene, polyurethane resin and water is 0.2:100:60; Wherein, polyurethane resin is made up of number average It is prepared from polytetrahydrofuran ether diol with a molecular weight of 5000 and 2,4,4-trimethylhexamethylene diisocyanate, and polytetrahydrofuran ether diol and 2,4,4-trimethylhexamethylene diisocyanate The molar ratio is 1.2:1.

[0038] According to the above raw material components, adopt the preparation method provided by the invention to prepare the required coating liquid of the present invention:

[0039] S101: Soak the graphene in an acid solution, and heat at 110° C. for 5 hours; wherein, in the acid solution, the solutes are sulfuric acid and phosphoric acid, and the weight ratio of sulfuric acid and phosphoric acid is 1:0.5;

[0040] S102: Add the remaining raw material components to t...

Embodiment 2

[0042] The invention provides a coating liquid, which comprises the following raw material components: graphene, polyurethane resin, water, polyvinyl alcohol with a number average molecular weight of 10,000, an alcoholysis degree of 85%, and polyvinyl alcohol with a number average molecular weight of 8,000. Ester and tourmaline powder; wherein, the mass ratio of graphene, polyurethane resin and water is 0.2:100:60; the mass ratio of polyvinyl alcohol, polyethyl acrylate, tourmaline powder and graphene is 3:1:2:1; Among them, the polyurethane resin is prepared from polytetrahydrofuran ether diol with a number average molecular weight of 5000 and 2,4,4-trimethylhexamethylene diisocyanate, and polytetrahydrofuran ether diol and 2,4,4-trimethyl The molar ratio of hexamethylene diisocyanate is 1.2:1.

[0043] According to the above raw material components, adopt the preparation method provided by the invention to prepare the required coating liquid of the present invention:

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com