Multi-dimensional nano-particle modified super-hydrophobic oil-absorbing foam material and preparation method thereof

A technology of nano-particles and foam materials, applied in the field of super-hydrophobic oil-absorbing foam materials, can solve the problems of single modified particle size, lack of chemical connection between particles and foam matrix, etc., and achieves low cost, simple preparation process, and improved adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

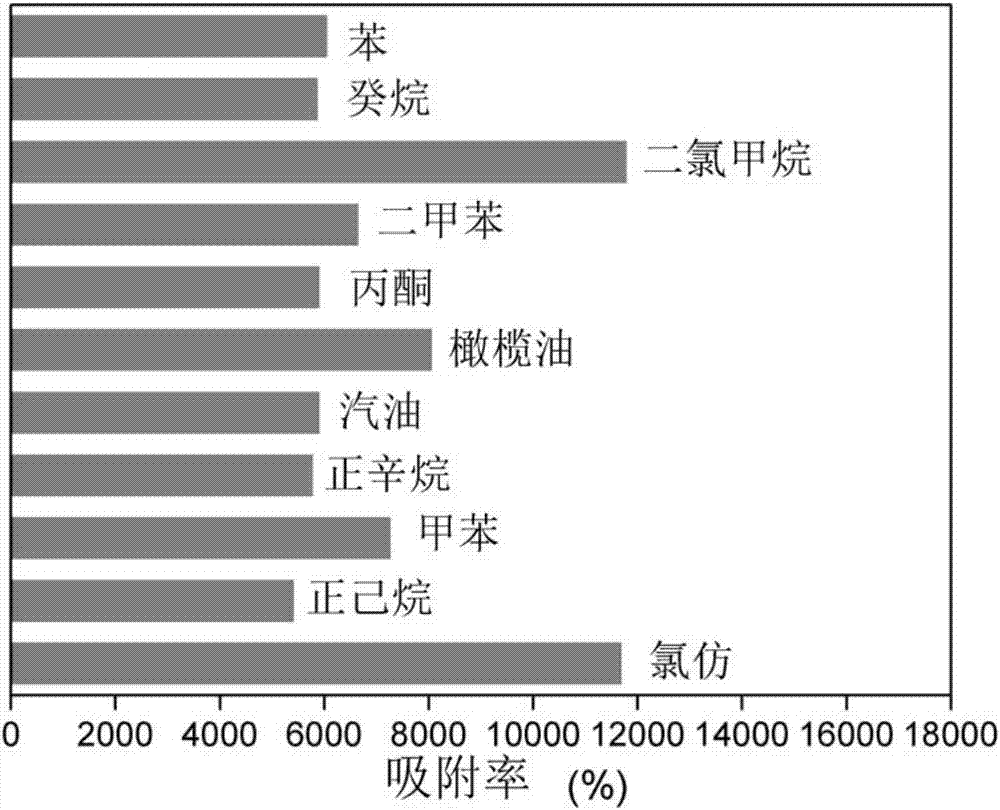

Examples

Embodiment 1

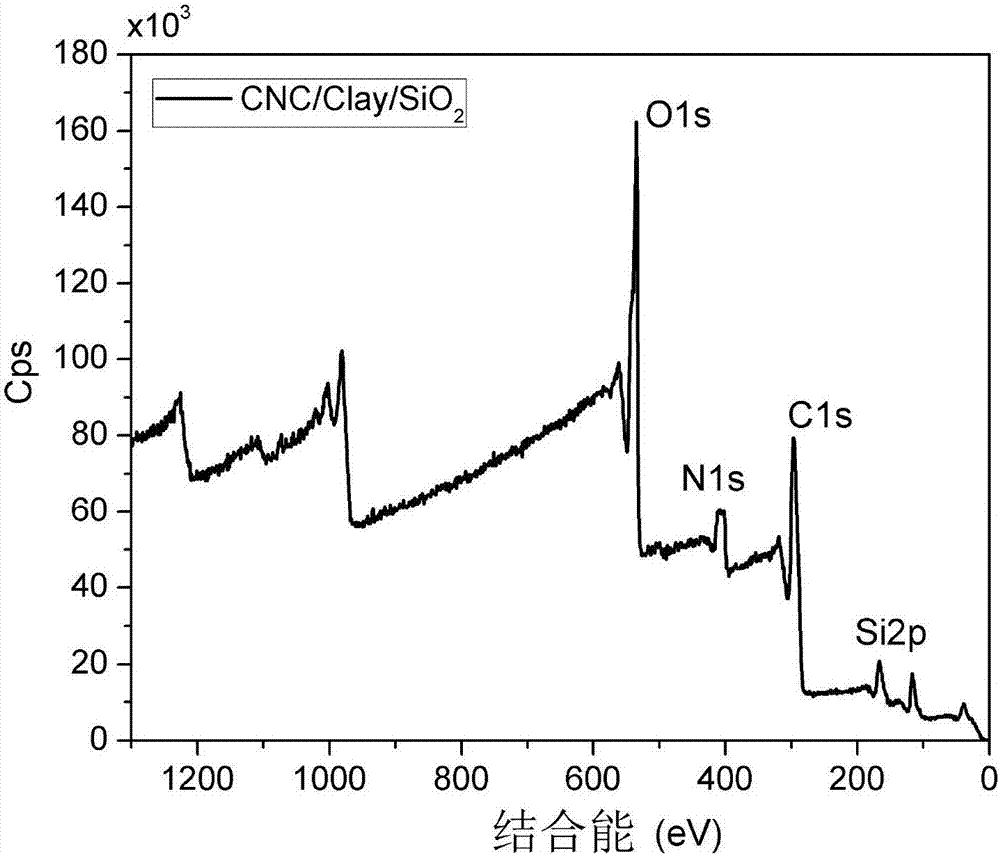

[0044] (1) Weigh 100 mg of silicon dioxide, 10 mg of nanocellulose, and 10 mg of nanoclay, respectively, and put them into a dry flask, add anhydrous dimethylformamide, seal the flask and sonicate for 1 hour to fully disperse the nanoparticles, and prepare A mass concentration of 5% silicon dioxide / nanocellulose / nanoclay nanoparticle mixed solution;

[0045] (2) Wash and dry the polyurethane foam in a 70vol% ethanol solution to clean the surface; immerse the dried foam material in a toluene solution containing 10wt% toluene diisocyanate, seal and react with stirring at 70°C for 1 hour, A modified foam material is obtained;

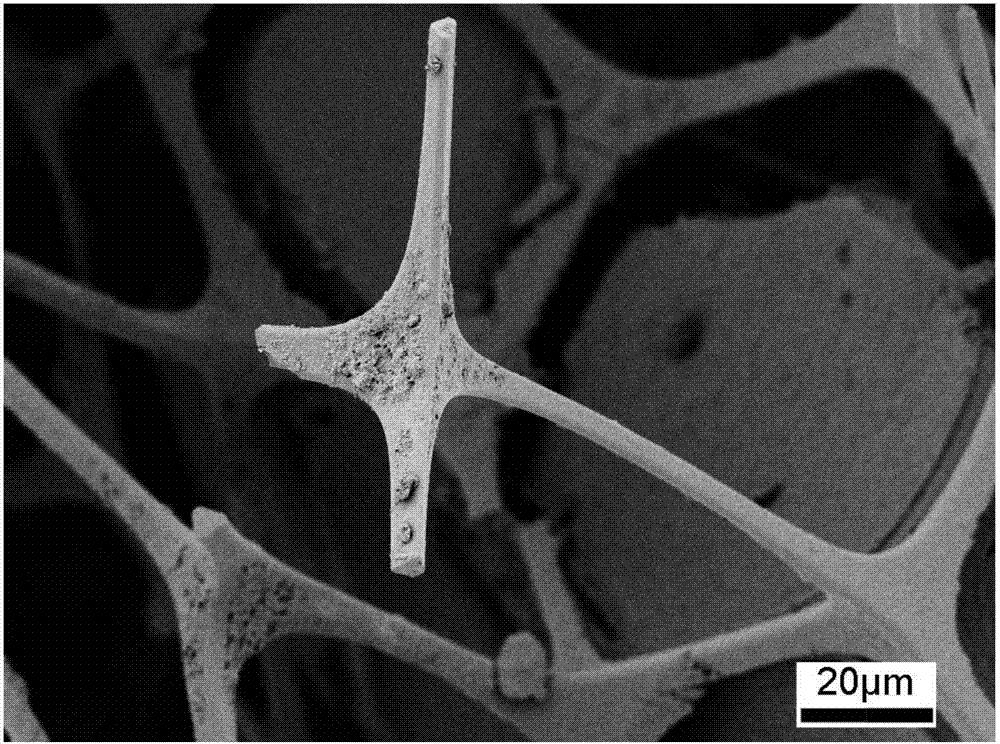

[0046] (3) Take out the modified foam material and quickly immerse it in the silica / nanocellulose / nanoclay nanoparticle mixture solution prepared in step (1), seal it and stir it at 70°C for 3 hours to obtain a surface-adhesive solution. Foam materials of branched nanoparticles;

[0047] (4) Wash and dry the foam material grafted with nanoparticles on the ...

Embodiment 2

[0052] (1) Weigh 10 mg of silicon dioxide titanium, 100 mg of carbon nanotubes and 100 mg of graphene oxide respectively, put them into a dry flask, add anhydrous dimethyl sulfoxide, and seal the flask with ultrasound for 2 hours to fully disperse the nanoparticles. Prepare a mixed solution of titanium dioxide / carbon nanotubes / graphene oxide nanoparticles with a mass concentration of 1%;

[0053] (2) Wash and dry the polyurethane foam in a 70vol% ethanol solution to clean the surface; immerse the dried foam material in a toluene solution containing 10wt% toluene diisocyanate, seal and react with stirring at 90°C for 3 hours, A modified foam material is obtained;

[0054] (3) Take out the modified foam material and quickly immerse it in the titanium dioxide / carbon nanotube / graphene oxide nanoparticle mixture solution prepared in step (1), seal it and stir it at 90°C for 1 hour to obtain surface grafting nanoparticle foam material;

[0055] (4) Repeat step (2) and step (3) twi...

Embodiment 3

[0060] (1) Weigh 100 mg of silica titanium, 50 mg of halloysite and 50 mg of graphene oxide respectively, put them into a dry flask, add anhydrous dimethyl sulfoxide, and seal the flask with ultrasound for 1.5 hours to fully disperse the nanoparticles and prepare the quality Concentration is 3% titanium dioxide / halloysite / graphene oxide nanoparticle mixture;

[0061] (2) Wash and dry the polyurethane foam in a 70vol% ethanol solution to clean the surface; immerse the dried foam material in a toluene solution containing 10wt% isophorone diisocyanate, seal and stir at 80°C for reaction 2 hours, obtain the modified foam material;

[0062] (3) Take out the modified foam material and quickly immerse it in the titanium dioxide / halloysite / graphene oxide nanoparticle mixture solution prepared in step (1), seal it and stir it at 80°C for 2 hours to obtain surface grafting nanoparticle foam material;

[0063] (4) Repeat steps (2) and (3) to graft two layers of composite nanoparticles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com