Method for solving problems of cracking of silicon dioxide thin film and glass coloring by utilizing methylene blue solution

A technology of silica and methylene blue, applied in chemical instruments and methods, water/sludge/sewage treatment, coating, etc., can solve the problems of poor improvement, complex process, etc., and achieve stress reduction and transparency Good performance, avoid cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Measure 8.926ml of water and 35.68ml of ethanol in a beaker, stir on a magnetic stirrer for 10 minutes to fully mix, then add 2.23ml of 1-n-butylamine to the beaker, stir for 30 minutes, and add it to the beaker after it is evenly mixed 4.46ml of tetraethylorthosilicate, stir and react for about 5min at room temperature and stand for 1-5min to form a sol.

Embodiment 2

[0028] Hang the cleaned glass substrate on the support, according to the SiO prepared in Example 1 2 The sol is put into the watering can before it is gelled, and sprayed on the glass substrate. The distance between the nozzle and the glass substrate is controlled at 3cm, and the spray is continuously sprayed for 3 times to obtain SiO-plated 2 Thin film glass substrate.

Embodiment 3

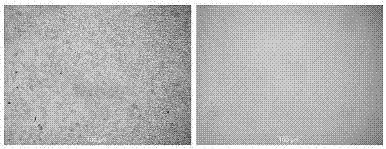

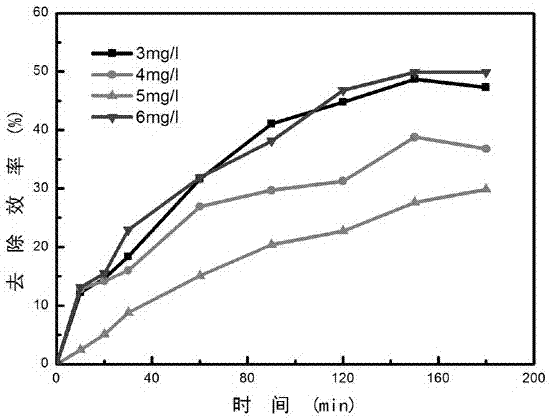

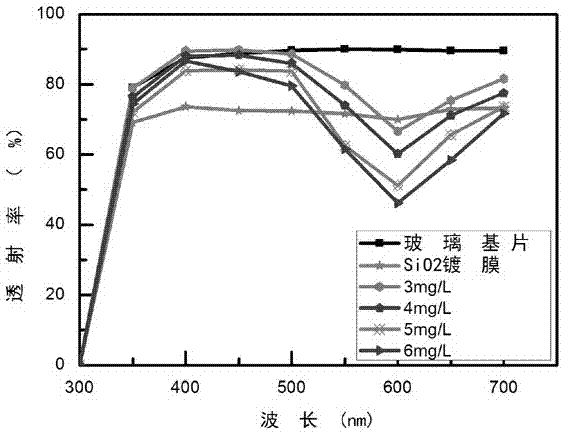

[0030] In Example 2 will be plated with SiO 2 The glass substrate of the thin film is allowed to stand in the air for 1-5 minutes. When the gel coat is not completely dried, immerse the glass substrate in the methylene blue solution of different concentration, and measure the absorbance of the solution every half an hour. After that, immersing it in the methylene blue solution works best. If the time is too short, the gel will not be completely gelled, and if the time is too long, the gel will dry and crack. So the SiO obtained by this method 2 The problem of film cracking is solved. The immersion time in the solution is not easy to be too long, 3h is the best, if the time is too long, the film will be damaged. Such as figure 1 figure 2 As shown, the film immersed in methylene blue is smooth, free of cracks, and basically non-porous structure. The removal efficiency of glass substrates immersed in different concentrations of methylene blue solution is as follows image 3 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com