A method for reducing energy consumption per ton of steel in rolling process

A technology of per ton of steel and energy consumption, applied in the field of reducing the energy consumption per ton of steel in the rolling process, can solve the problems of high transformation cost and poor control accuracy, and achieve the effect of shortening the construction period, maintaining stable power consumption, and solving experience limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

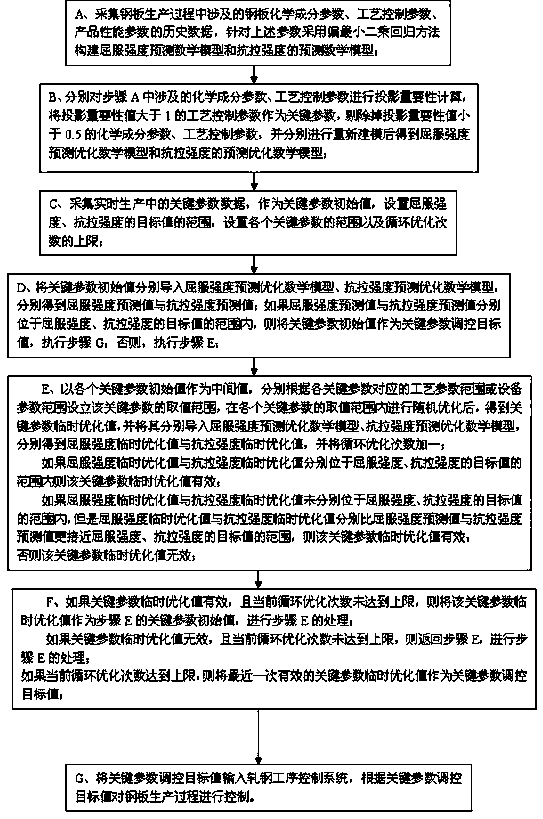

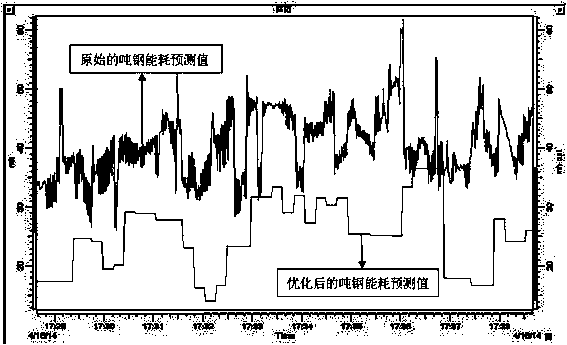

[0050] Such as figure 1 As shown, in this embodiment, a typical hot-rolled product with a thickness of SS400 steel plate of 7.5mm is represented, and the method for reducing the energy consumption per ton of steel in the rolling process provided includes the following steps:

[0051] A. Collect the historical data of the key parameters involved in the steel rolling process, and use the partial least squares regression method to construct the mathematical model of the furnace temperature and the mathematical model of the energy consumption per ton of steel;

[0052] The key parameters involved in the rolling process are: the temperature and time of the billet entering the furnace, the temperature and time of the preheating section, the temperature and time of the first heating section, the temperature and time of the second heating section, the temperature and time of the third heating section, and the temperature of the soaking section and time;

[0053] Described partial lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com