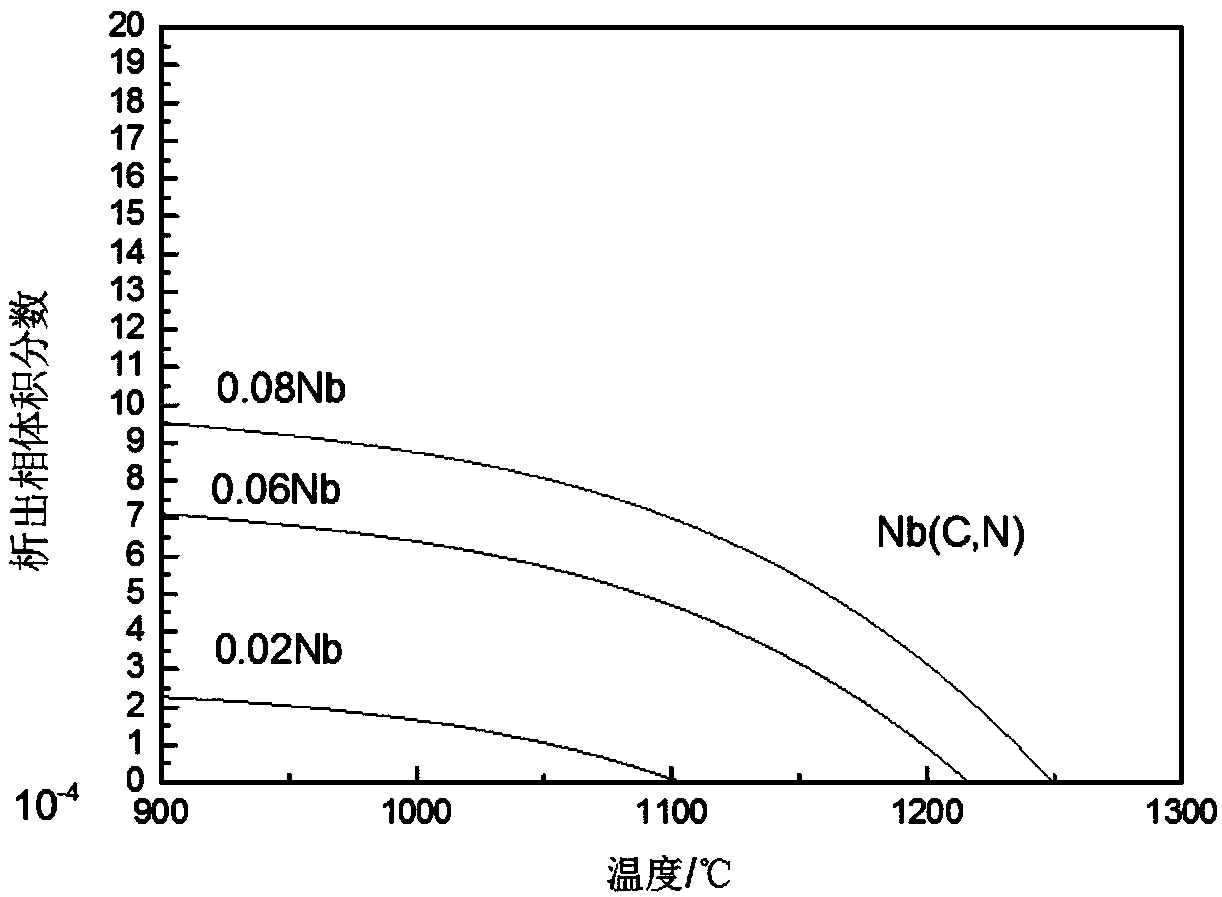

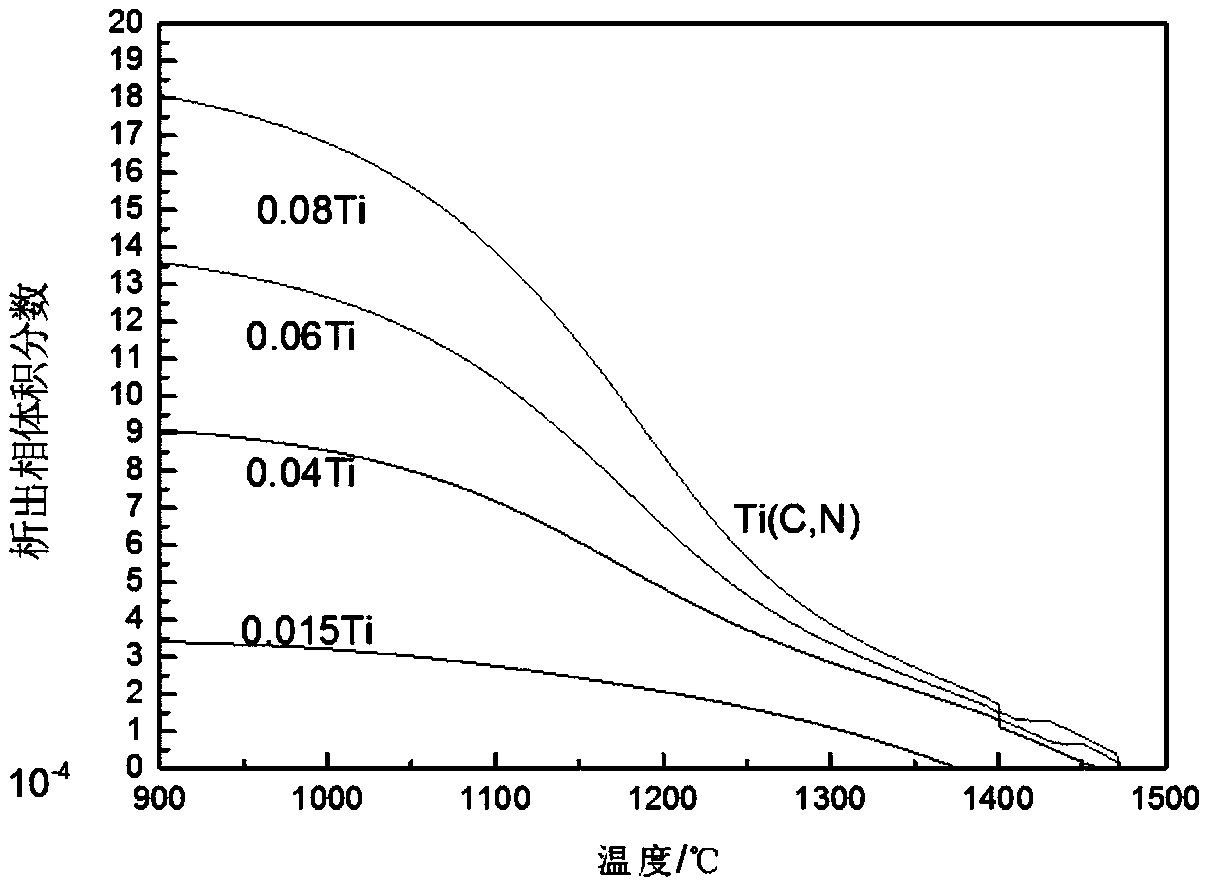

Steel for Nb-Ti composite microalloyed high-temperature vacuum carburizing heavy-duty gear

A high-temperature vacuum and micro-alloying technology, applied in the field of alloy carburizing steel, can solve the problems of long process cycle and low carburizing temperature, and achieve the effects of improving production efficiency, increasing carburizing temperature and reducing development cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] The invention steel and the comparison steel were subjected to simulated carburizing and quenching experiments. The experimental equipment was a high-temperature atmosphere furnace. The simulated carburizing and quenching process was as follows: all samples were heated up with the furnace, and then heated to the set carburizing temperature. The simulated carburizing temperatures were 950 ℃, 1000℃, 1050℃, 1100℃, 1150℃, keep warm at different temperatures for 1h, 2h, 4h, 8h respectively, then quickly perform water quenching, and finally take samples to observe the grain size under various process conditions, according to GB / T 6394-2002 evaluates its austenite grain size grade, and the experimental results are shown in Table 2-5.

[0033] It can be seen that after the steel of the present invention is treated by the simulated carburizing process at 950°C, its austenite grain size grade remains at 8, and no abnormal growth phenomenon is found; after the simulated carburizin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com