Coking plant coke oven gas utilization and flue gas treatment system and method

A flue gas treatment system and coke oven gas technology, which are applied in the field of energy saving and emission reduction in the coking industry, can solve the problems of low temperature denitration treatment of coke oven exhaust gas, reduce project investment and floor space, reduce construction costs, reduce The effect of floor space and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

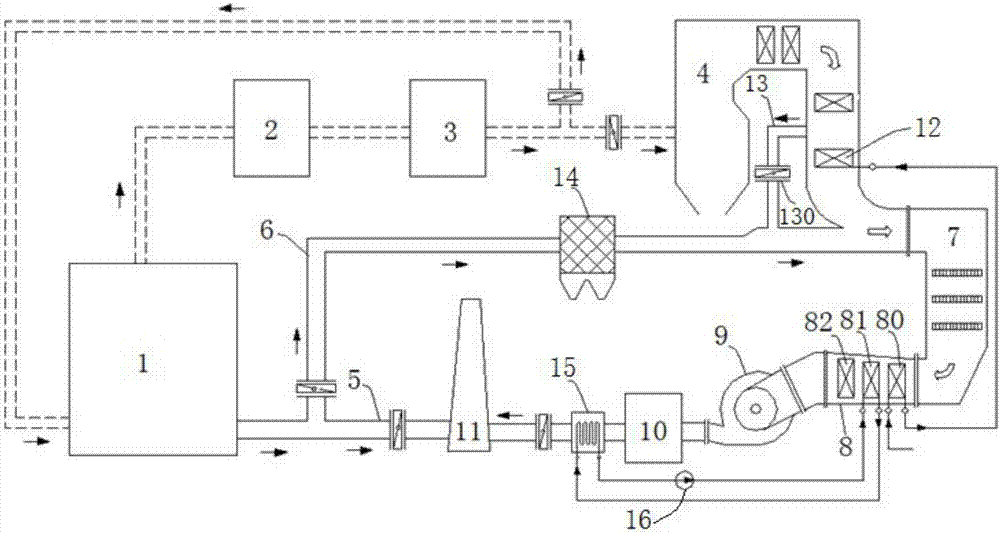

[0040] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0041] see figure 1 , A coking plant coke oven gas utilization and flue gas treatment system, including at least coke oven 1, gas treatment device 2, coke oven gas boiler 4, coke oven exhaust gas flue one 5, coke oven exhaust gas flue two 6, and denitration device 7. Waste heat recovery flue 8, induced draft fan 9, desulfurization device 10 and chimney 11,

[0042] The raw gas outlet of the coke oven 1 is connected to the gas treatment device 2 through a pipeline;

[0043] The gas outlet of the gas processing device 2 is connected to the coke oven gas boiler 4 through a pipeline;

[0044] The flue gas outlet of the coke oven 1 communicates with the chimney 11 through the coke oven exhaust gas flue one 5, and the flue gas outlet of the coke oven 1 also communicates with the high temperature flue of the coke oven gas boiler 4 through the coke oven fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com