Sound insulation heat preservation layer mechanism

A thermal insulation layer and sound insulation technology, applied in the direction of roof insulation materials, etc., can solve the problems of inability to achieve sound insulation and noise elimination effects, unfavorable popularization and application of ordinary residential buildings, and high cost of vacuum glass, and achieve light weight, small heat capacity, and high heat dissipation. The effect of sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

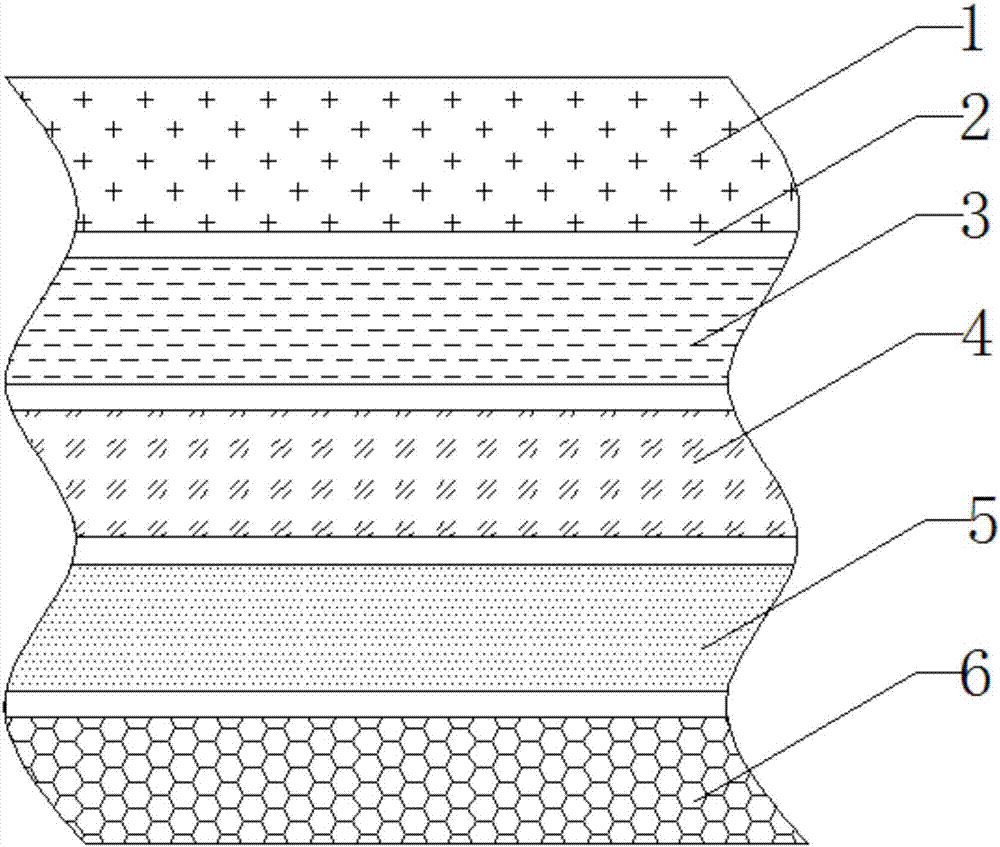

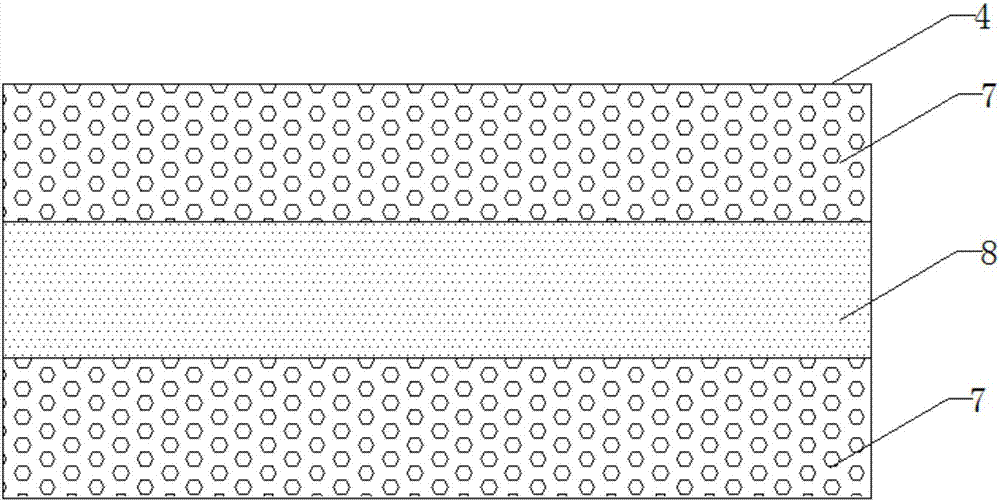

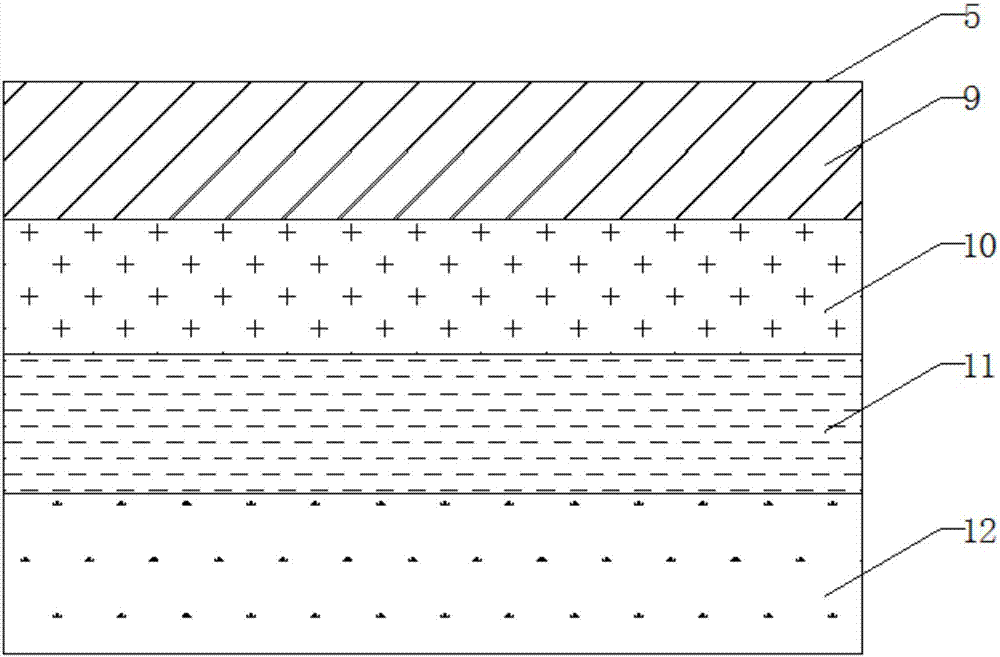

[0021] Specific implementation method: When in use, the mechanism can avoid being corroded in harsh environments through the anti-corrosion layer 6. The waterproof layer 1 of powdery hydrophobic material can automatically fill and close when encountering cracks, and has good waterproof performance. Shock pad 3 can reduce the vibration of the mechanism. The sound-absorbing cotton 7 and the sound-insulating board 8 in the sound-insulating layer 4 can respectively absorb and insulate the sound, and the effect of sound insulation is more thorough. 10, thermal insulation cotton 11 and extruded board 12, not only thermal insulation, but also environmental protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com