Preparation method of sun-screening agent for decorative paper production

A technology of sunscreen and decorative paper, which is applied in the direction of adding anti-aging agent for paper, paper, paper making, etc. It can solve the problems of high cost, poor decorative paper, and poor use effect, and achieves simple operation, good preparation cost, and modified uniform effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

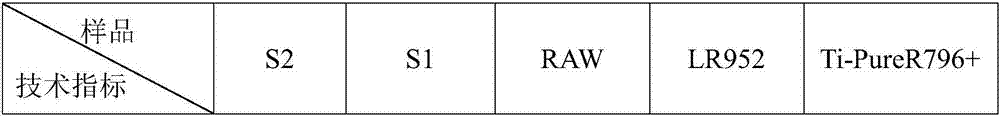

Image

Examples

Embodiment Construction

[0020] The invention relates to a method for preparing a sunscreen agent for decorative paper production. The preparation process of the method is based on the mechanochemical intercalation of kaolinite, using kaolinite, polyethylene glycol, and nano-titanium dioxide as raw materials. After being mixed with desalinated water to form a slurry, it is ground, dispersed, aged, dried and crushed in sequence to finally obtain a sunscreen that can be used to improve the sunscreen and anti-aging performance of decorative paper. The preparation method of the sunscreen specifically includes the following steps:

[0021] A. Grinding

[0022] Mix kaolinite, polyethylene glycol, and nano-titanium dioxide with a mass ratio of 100:11:11 in desalted water to form a slurry with a concentration of 650g / L. The particle size of kaolinite is ≤2μm, and polyethylene glycol is nano-titanium dioxide. It is an excellent dispersant for pigment titanium dioxide in the process of dispersion and papermakin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com