Mining coal dust based hole-sealing and grouting material, and preparation hole-sealing process

A technology of grouting materials and coal chips, which is applied in the directions of sealing/packing, drilling composition, earthwork drilling, etc., can solve the problems of high cost of sealing holes, reducing the efficiency of gas drainage, and hidden dangers in safe production. Achieve the effects of improving flexibility and reliability, improving resource recovery and utilization, and improving the characteristics of high coal affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

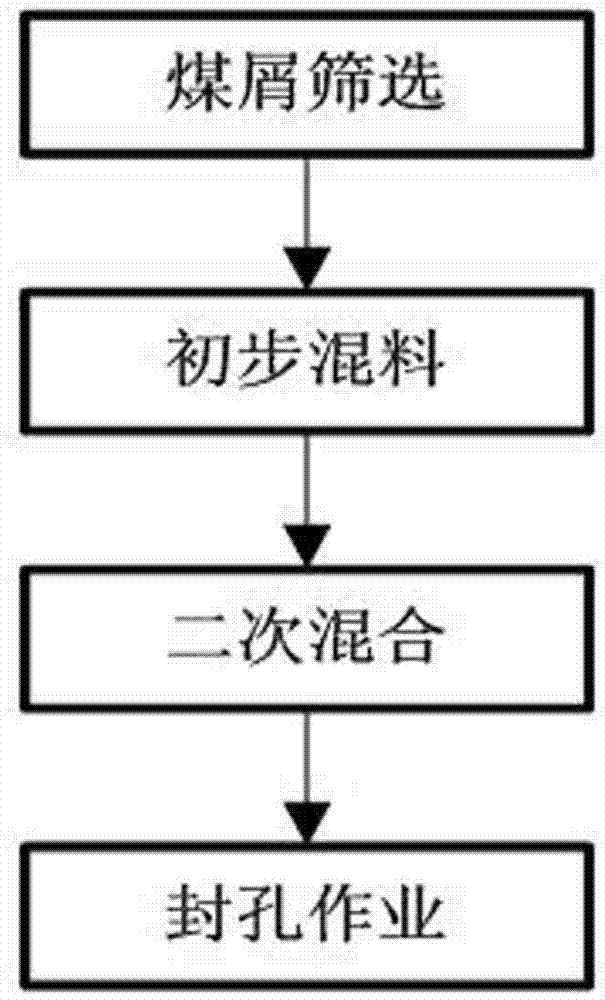

[0023] Such as figure 1 As shown, a mining coal dust-based sealing grouting material is composed of the following materials in parts by mass: coal dust 15.87%, urea-formaldehyde resin 31.75%, oxalic acid 0.93%, silicon powder 3.17%, calcium carbonate 0.32%, 0.63% of hydroxypropyl methylcellulose, 0.16% of coupling agent, and the balance is water.

[0024] In this embodiment, the coal chips are pulverized coal particles with a diameter of less than 2mm.

[0025] In this embodiment, the mesh size of the silicon powder is 200-300 mesh.

[0026] In this embodiment, the coupling agent is silane coupling agent KH560.

[0027] A preparation and sealing process of coal dust-based sealing grouting material for mining, comprising the following steps:

[0028] The first step is coal dust screening, using the coal dust particles produced during the drilling construction process as the base material for the sealing material, and using the screening device to screen the coal dust particl...

Embodiment 2

[0034] A mining coal dust-based sealing grouting material, which is composed of the following substances in parts by mass: coal dust 28.65%, binder 31.75%, crosslinking agent 0.48%, reinforcing agent 6.17%, expansion agent 0.62%, toughening agent Agent 0.63%, coupling agent 0.57%, and the balance is water.

[0035] In this embodiment, the coal chips are pulverized coal particles with a diameter of less than 2mm.

[0036] In this embodiment, the binder is urea-formaldehyde resin.

[0037] In this embodiment, the crosslinking agent is oxalic acid.

[0038] In this embodiment, the expansion agent is calcium carbonate.

[0039] In this embodiment, the reinforcing agent is silicon powder, and the mesh size of the silicon powder is 200-300 mesh.

[0040] In this embodiment, the toughening agent is hydroxypropyl methylcellulose.

[0041] In this embodiment, the coupling agent is silane coupling agent KH560.

[0042] A preparation and sealing process of coal dust-based sealing gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com