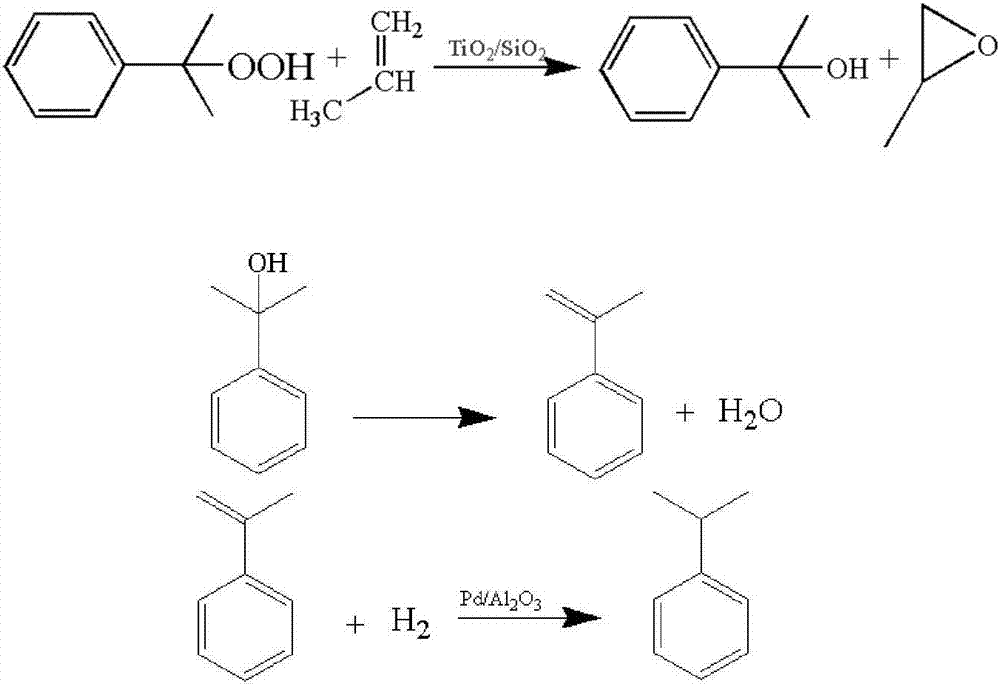

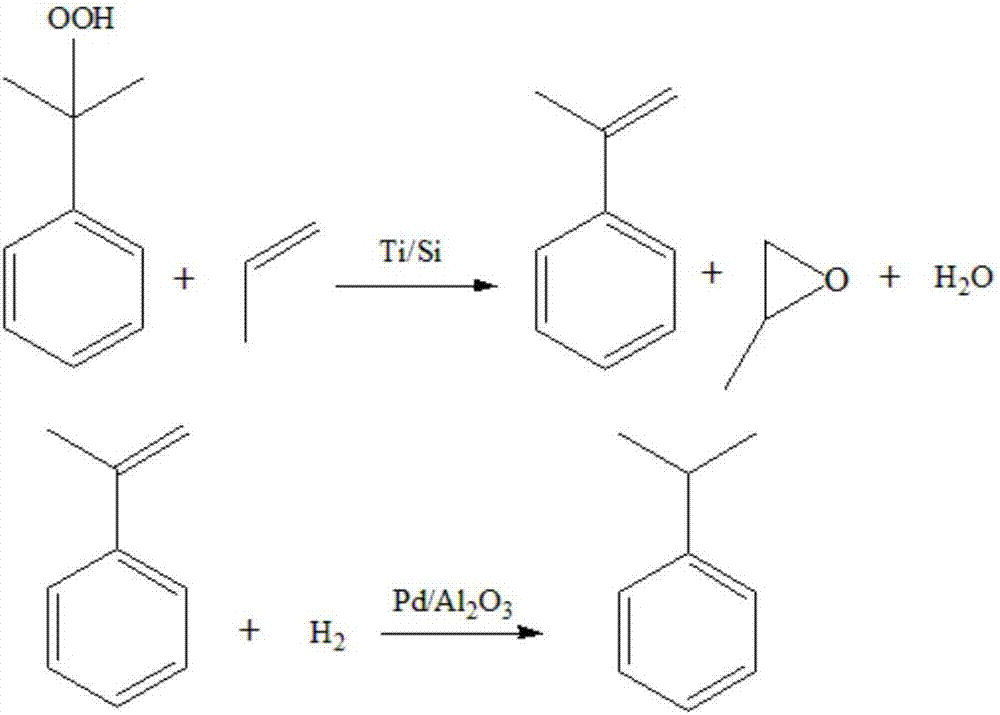

Titanium-silicon molecular sieve catalyst, preparation method thereof and application thereof in production of propylene oxide

A technology of titanium-silicon molecular sieve and propylene oxide, which is applied in the direction of molecular sieve catalysts, bulk chemical production, chemical instruments and methods, etc., can solve the problems of large fluctuations in market demand for by-products, high explosion-proof grades, and short processes, and achieve savings Effects of dehydration process, prolonging service life and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation process of the titanium-silicon molecular sieve catalyst is as follows: under normal pressure, 1g of all-silicon molecular sieve carrier powder is purged at 500°C for 0.3h under a nitrogen heat flow of 200ml / min to remove moisture, and then the temperature is rapidly raised to 850°C, and the temperature difference is controlled during the heating process. within ±1°C. In the vacuum evaporator, TiCl 4 It sublimes into a gas at 850°C. Under the protection of nitrogen flow, add to the SiO 2 In the reactor of the carrier, the nitrogen flow rate is controlled to be 100ml / min, and TiCl is continuously fed into the quartz tube reactor equipped with the carrier. 4 , allowing the particles to settle freely on the surface of the molecular sieve carrier. When the loading phase is over, use 400°C, 100ml / min dry nitrogen flow to continue purging for 1h to remove the remaining TiCl inside the reactor 4 Steam, followed by continuous calcination at 500-600°C for 3h ...

Embodiment 1

[0058] Weigh 2g of the titanium-silicon molecular sieve catalyst prepared by the above method with a particle size of 0.3-0.6mm, and fill it in a 304L stainless steel fixed-bed reactor with an inner diameter of 15mm. It is 36kg. The mass fraction of CHP is 40%, and the remaining solvent is cumene. Propylene is fed into the reactor by pumping the liquid phase. During the reaction, the amount of propylene is excessive, and the total mass space velocity in the fixed bed is controlled to be 6h -1 , The end of the device is equipped with a gas-liquid separation tank, the separation tank is cooled by chilled water, the material is collected every ten minutes, samples are taken, and the product composition is analyzed by gas chromatography. The calculated conversion rate C of CHP CHP =91.4%, PO yield P PO =84.2%, CHP selectivity S PO =92.1%, the mass fraction of water shown in the moisture meter is 3.7%. From the above data, it can be seen that by precisely controlling the confi...

Embodiment 2

[0060] Reaction temperature is 90 DEG C, continuous reaction 0.5h, other conditions are the same as embodiment 1, collect material and carry out chromatographic detection, the conversion rate of CHP is C CHP =93.2%, PO yield P PO =86.3%, CHP selectivity S PO = 92.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com