Shaft furnace burden breathability test device and test method

A testing device and testing method technology, applied in the direction of measurement device, analysis material, permeability/surface area analysis, etc., can solve the problems of not considering the resistance loss of the material column, not suitable for the measurement of the gas permeability of the shaft furnace charge, etc., to achieve a simple device. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

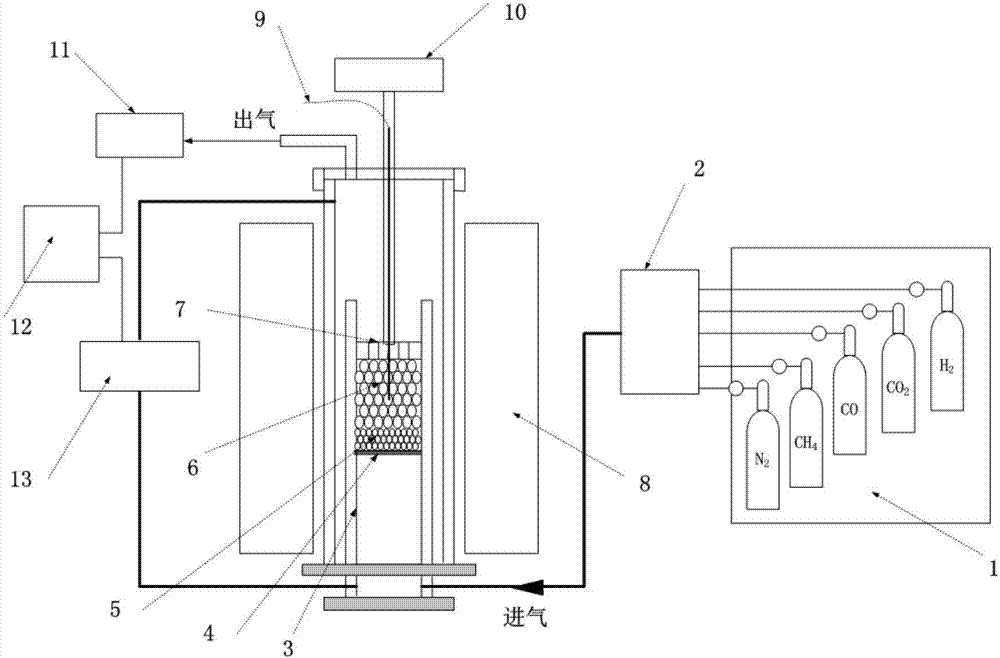

[0051] The test uses 500g of high-grade iron concentrate oxidation pellets with a particle size of 10-12.5mm. The diameter of the shaft furnace reaction tube is 6cm. The grid orifice plate and alumina balls are pre-installed in the shaft furnace reaction tube before loading the iron concentrate pellets. Put a porous graphite plate on the upper part of the pellet sample, insert a thermocouple into the center of the pellet sample, then cover and seal the upper part of the reaction tube, and then put the reaction tube into the hearth of the high-temperature furnace. according to figure 1 As shown, connect the intake equipment, differential pressure transmitter, reducing gas analyzer and computer acquisition system respectively. After completing all the preparatory work, open the valves of each gas cylinder, and open each system software of the computer to start the test. First, heat the charge to 400°C at a rate of 10°C / min through an electric furnace, during which 5L / min of N ...

Embodiment 2

[0055] 500g of laterite nickel ore oxide pellets with a particle size of 10-12.5mm were used in the test. The diameter of the shaft furnace reaction tube was 6cm. The grid orifice plate and alumina balls were pre-installed in the shaft furnace reaction tube before loading the oxide pellets. Put a porous graphite plate on the upper part of the pellet sample, insert a thermocouple into the center of the pellet sample, then cover and seal the upper part of the reaction tube, and then put the reaction tube into the hearth of the high-temperature furnace. according to figure 1 As shown, connect the intake equipment, differential pressure transmitter, reducing gas analyzer and computer acquisition system respectively. After completing all the preparatory work, open the valves of each gas cylinder, and open each system software of the computer to start the test. First, heat the charge to 400°C at a rate of 10°C / min through an electric furnace, during which 5L / min of N 2 For protect...

Embodiment 3

[0058] The test uses 500g of vanadium-titanium-iron concentrate oxidation pellets with a particle size of 10-12.5mm. The diameter of the shaft furnace reaction tube is 6cm. The grid orifice plate and alumina balls are pre-installed in the shaft furnace reaction tube before loading the oxide balls. group. Put a porous graphite plate on the upper part of the pellet sample, insert a thermocouple into the center of the pellet sample, then cover and seal the upper part of the reaction tube, and then put the reaction tube into the hearth of the high-temperature furnace. according to figure 1 As shown, connect the intake equipment, differential pressure transmitter, reducing gas analyzer and computer acquisition system respectively. After completing all the preparatory work, open the valves of each gas cylinder, and open each system software of the computer to start the test. First, heat the charge to 400°C at a rate of 10°C / min through an electric furnace, during which 5L / min of N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com