Metallurgical furnace

A metallurgical furnace and furnace body technology, applied in the field of metallurgical furnaces, can solve the problems of difficulty in building a laterite ore smelter, using a large amount, and high cost of smelting laterite ore, so as to reduce direct discharge and operation of adding melt, and increase the amount of slag storage , The effect of reducing the consumption of tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

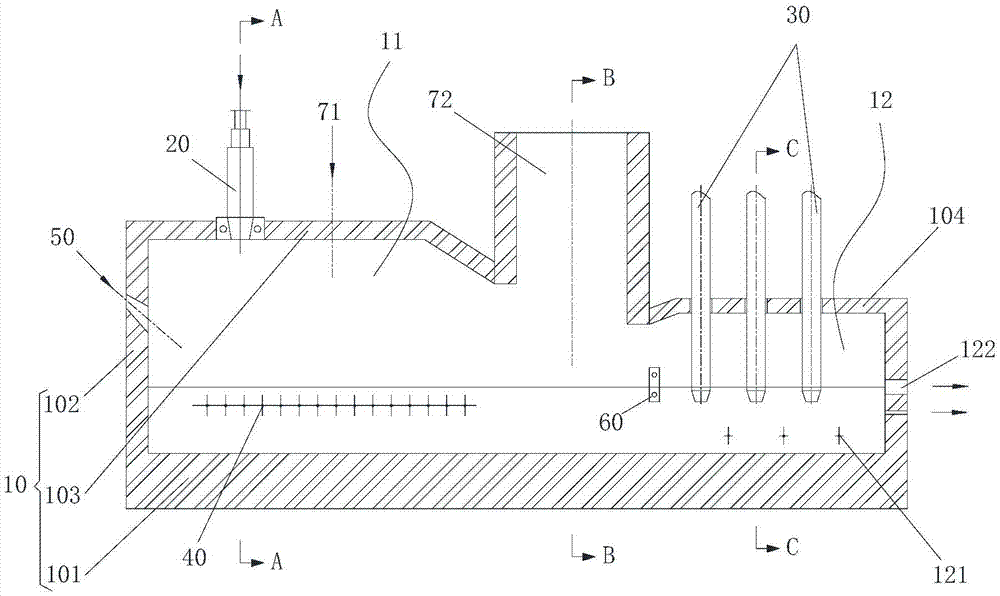

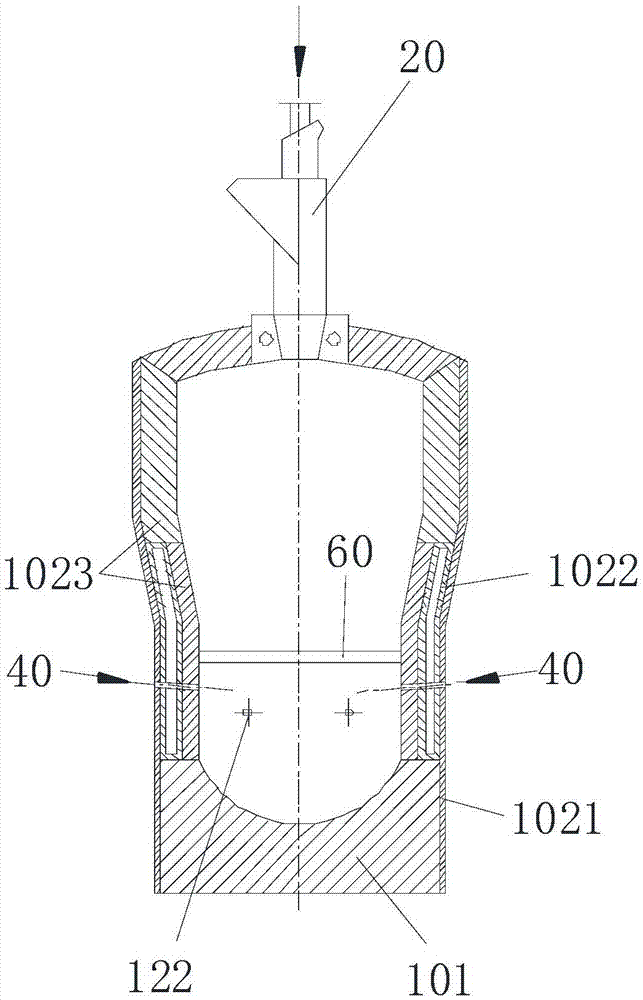

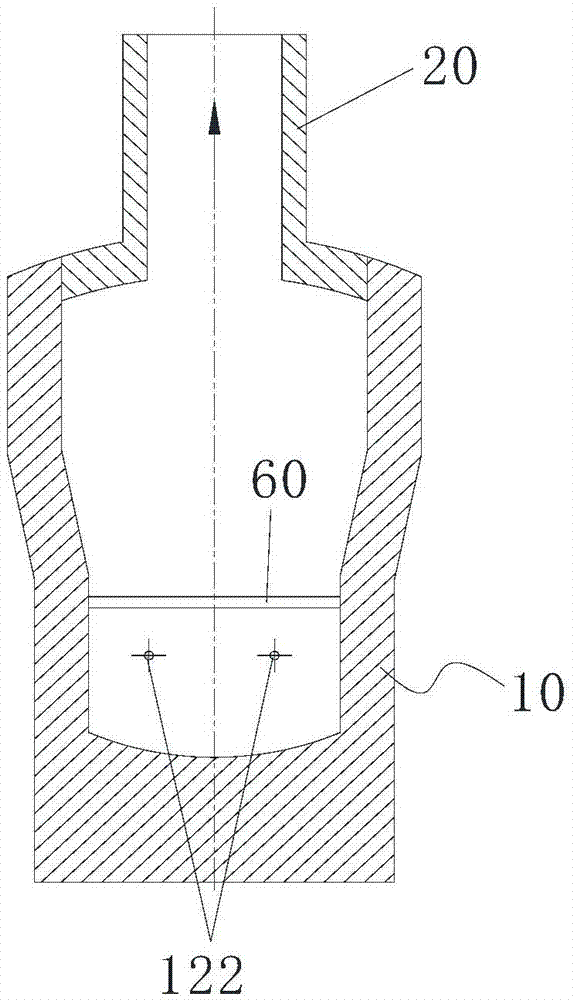

[0035] The central axis of the furnace body 10 is the axis extending from the melting and reduction chamber 11 to the depletion chamber 12, and the furnace body 10 is arranged symmetrically with respect to the central axis.

[0036] Such as Figure 1 to Figure 4 As shown, the furnace body 10 of the metallurgical furnace of the embodiment of the present invention is formed with a melting reduction chamber 11 and a depletion chamber 12 communicating with each other. The main function of the cavity 11 is to form a high temperature zone where the heat is concentrated, where the mineral material is melted, and the main nozzle 20 is used to spray the mineral material into the melting reduction cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com