A kind of fracturing fluid and preparation method thereof

A fracturing fluid and thickener technology, applied in the field of fracturing fluid, can solve the problems of poor temperature resistance and shear resistance, complex additive components, high residue content, etc., and achieve good temperature resistance and shear resistance, thickener The effect of small dosage and low residue content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

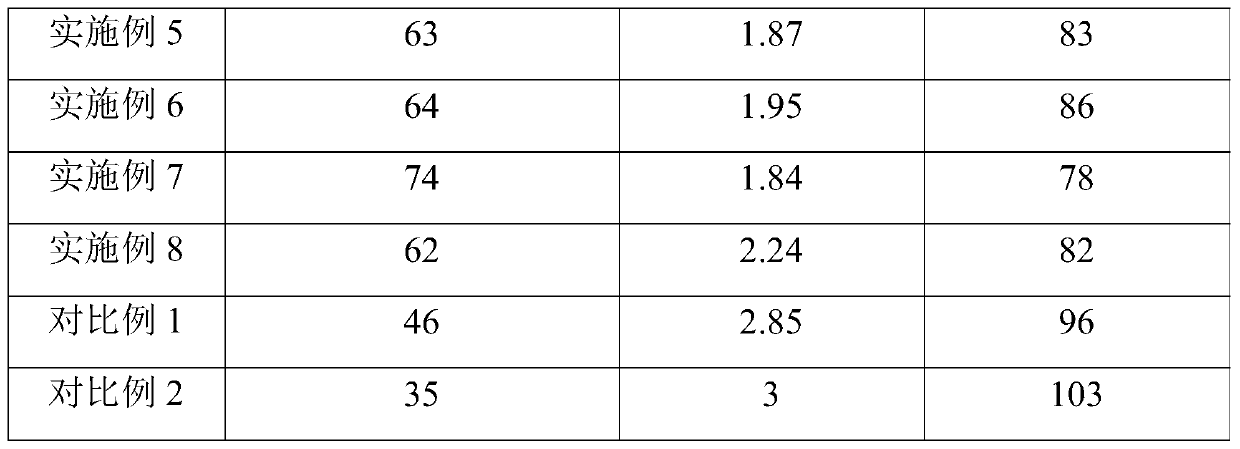

Examples

preparation example Construction

[0031] In the present invention, the preparation method of the organic zirconium mixture preferably includes: reacting zirconium oxychloride, glycerin, sodium lactate, sodium hydroxide and water at 50-70°C for 4-6h, wherein, zirconium oxychloride, glycerin The weight ratio of alcohol, sodium lactate, sodium hydroxide and water is preferably 1:0.4-0.7:0.8-1:0.5-0.8:1.2-1.6.

[0032] In the present invention, the gel breaker can adopt various gel breakers commonly used in the art, preferably at least one of ammonium persulfate, sodium persulfate, potassium persulfate and capsule gel breakers.

[0033] In a second aspect, the present invention provides a method for preparing fracturing fluid, the method comprising:

[0034] (1) Under stirring, add thickener I and thickener II to the water, then add clay stabilizer, bactericide, pH regulator, stir evenly to obtain the original glue solution, and then let it stand for 3-5h;

[0035] (2) Add gel breaker, then add crosslinking agent...

Embodiment 1

[0044] This example is used to illustrate the fracturing fluid of the present invention and its preparation method.

[0045] Add 0.4 parts by weight of nonionic polyacrylamide (purchased from Beijing Hengju, with a viscosity average molecular weight of 6 million) and 0.2 parts by weight of hydroxyethyl carboxymethylcellulose (purchased from Beijing Hengju) to 98.11 parts by weight of water under stirring at 5000 rpm Hubei Xiangtai Cellulose Co., Ltd., viscosity of 1% by weight aqueous solution: 60000mPa.s, degree of substitution: hydroxyethyl MS=1.8, carboxymethyl DS=0.2), then add 0.5 parts by weight of potassium chloride, 0.15 parts by weight of Formaldehyde and 0.06 parts by weight of hydrochloric acid (concentration is 37% by weight, parts by weight are calculated as HCl), stirred for 40 minutes to obtain the original glue solution, and then left to swell for 4 hours.

[0046] Take 99.42 parts by weight of the swollen original rubber solution and add 0.5 parts by weight of...

Embodiment 2

[0049] This example is used to illustrate the fracturing fluid of the present invention and its preparation method.

[0050] Add 0.27 parts by weight of nonionic polyacrylamide (purchased from Beijing Hengju, with a viscosity average molecular weight of 10 million) and 0.225 parts by weight of hydroxyethyl carboxymethylcellulose (purchased from Beijing Hengju) to 98.145 parts by weight of water under 4000rpm stirring Guangzhou Jinhua Chemical Technology Co., Ltd., viscosity of 1% by weight aqueous solution: 40000mPa.s, degree of substitution: hydroxyethyl MS=1.5, carboxymethyl DS=0.4), then add 0.8 parts by weight of ammonium chloride, 0.1 parts by weight of The sulfuric acid of glutaraldehyde, 0.02 weight part (concentration is 98 weight %, weight part is H 2 SO 4 meter), stirred for 20min to obtain the original gum solution, and then left to swell for 3h.

[0051] Take 99.56 parts by weight of the original rubber solution after swelling and add 0.4 parts by weight of an or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com