A kind of pig farm wastewater advanced treatment and resource recycling method

A pig farm wastewater and advanced treatment technology, which is applied in the direction of animal husbandry wastewater treatment, water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problem of inability to realize the resource utilization of coagulation sludge and the inability to reflect the removal effect of TP and COD , Dealing with high cost and other issues, achieving the effect of realizing high value-added recycling, realizing resource utilization, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

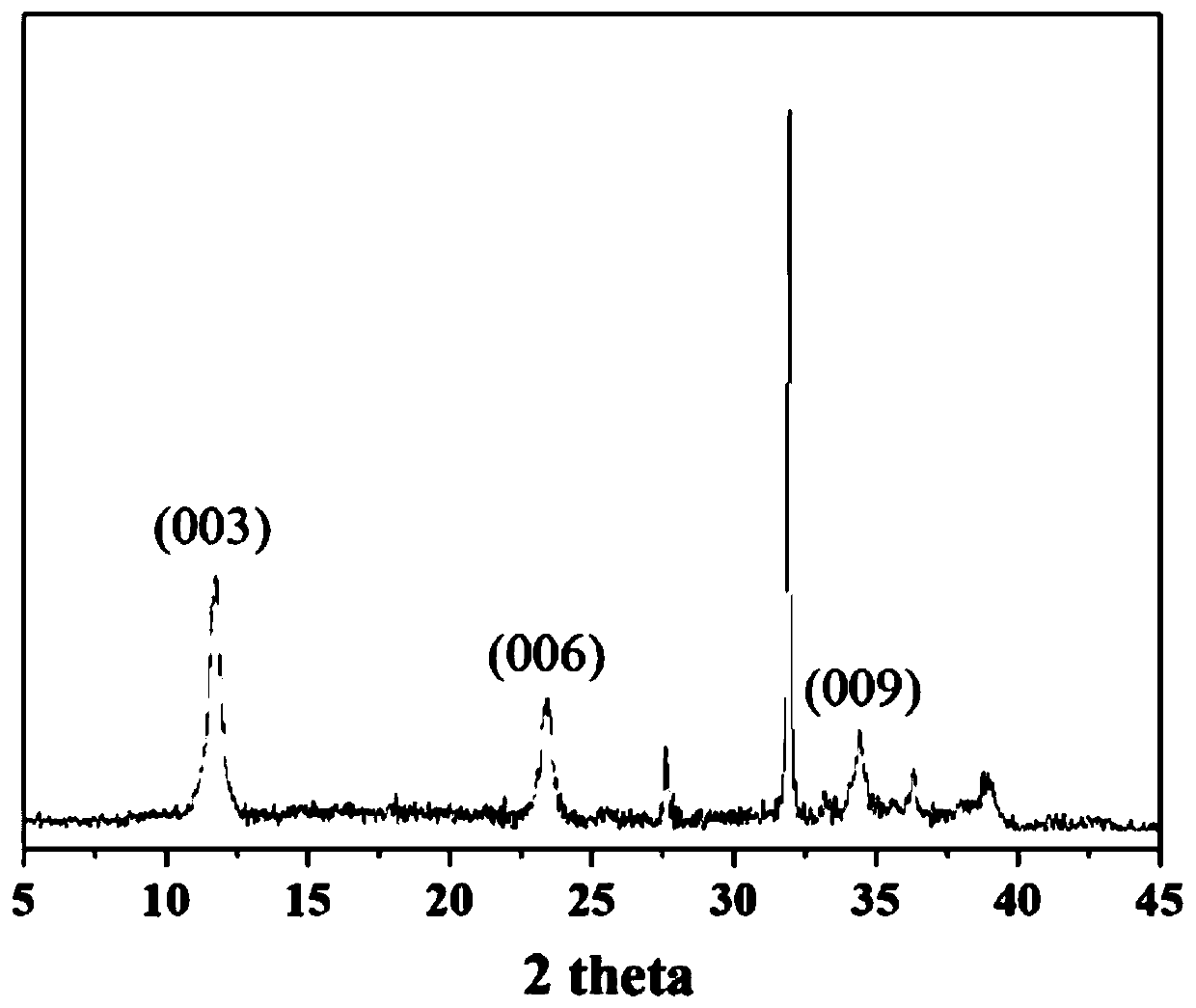

Method used

Image

Examples

Embodiment 1

[0050] A method for advanced treatment and resource recycling of pig farm wastewater, comprising the following steps:

[0051] (1) Accurately weigh 12.10g FeCl 3 ·6H 2 O (0.045mol Fe) and 36.40g MgCl 2 ·6H 2 O (0.179mol Mg), was dissolved in 1L of clear water simultaneously, and mixed metal salt solution was obtained after stirring and dissolving (at this time, the metal cation molar concentration of the gained mixed salt solution Mg:Fe=4:1);

[0052] (2) Weigh Na 2 CO 3 Add it to 1L of pig farm wastewater (obtained from a pig farm in Huizhou), adjust the pH=8 to 9, and stir for 30 minutes to obtain pig farm wastewater I;

[0053] (3) Accurately weigh 1.0g of biochar into 1L of pig farm waste water I obtained in step (2), make the biochar concentration 1g / L, stir at 50r / min for 20min, then stir and add 10mL of step (1) The mixed metal salt solution obtained in the MgFe mass concentration [Mg 2+ ]+[Fe 3+ ]=100mg / L, turn 5min under the condition of 150r / min, turn 30min u...

Embodiment 2

[0060] A method for advanced treatment and resource recycling of pig farm wastewater, comprising the following steps:

[0061] (1) Accurately weigh 12.10g FeCl 3 ·6H 2 O (0.045mol Fe) and 18.20g MgCl 2 ·6H 2 O (0.090mol Mg), was dissolved in 1L of clear water simultaneously, and mixed metal salt solution was obtained after stirring and dissolving (at this time, the metal cation molar concentration of the mixed salt solution of the gained Mg:Fe=2:1);

[0062] (2) Weigh Na 2 CO 3 Add it to 1L of pig farm wastewater (obtained from a pig farm in Huizhou), pH = 8-9, stir for 30 minutes to obtain pig farm wastewater I;

[0063] (3) Accurately weigh 0.1g of biochar into the 1L pig farm waste water I obtained in step (2), make the concentration of biochar be 0.1g / L, stir at 200r / min for 10min, then stir and add 6mL of step (1 ) in the mixed metal salt solution obtained, so that the MgFe mass concentration [Mg 2+ ]+[Fe 3+ ]=60mg / L, turn 2min under the condition of 200r / min, tur...

Embodiment 3

[0067] A method for advanced treatment and resource recycling of pig farm wastewater, comprising the following steps:

[0068] (1) Accurately weigh 12.10g FeCl 3 ·6H 2 O (0.045mol Fe) and 27.30g MgCl 2 ·6H 2 O (0.134mol / L Mg), was dissolved in 1L of clear water simultaneously, and mixed metal salt solution was obtained after stirring and dissolving (at this time, the metal cation molar concentration of the gained mixed salt solution Mg:Fe=3:1);

[0069] (2) Weigh Na 2 CO 3 Added to 1L pig farm wastewater (obtained from a pig farm in Huizhou), pH = 7-8, stirred for 30min to obtain pig farm wastewater I;

[0070] (3) Accurately weigh 0.5 biochar into 1L pig farm waste water I obtained in step (2), make the biochar concentration 0.5g / L, stir at 100r / min for 15min, and then add 8mL in step (1) The obtained mixed metal salt solution makes the MgFe mass concentration [Mg 2+ ]+[Fe 3+ ]=80mg / L, turn 3min under the condition of 100r / min, turn 25min under the condition of 75r / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com