Preparation method of photocatalyst

A photocatalyst and catalyst technology, applied in the chemical industry, can solve the problems of different reduction rates, inability to be widely used, unsatisfactory catalytic activity of bimetallic nanoparticles, etc., and achieve good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, the preparation method of the present embodiment is:

[0035] Configuration of Cinnamomum camphora leaf extract: Weigh 2.0 g of Cinnamomum camphora leaf powder into a 250 mL Erlenmeyer flask, add 100 mL of deionized water, shake in a shaker (30°C, 150 rpm) for 4 hours, filter to obtain the filtrate, That is 20 g / L of cinnamon camphor leaf extract;

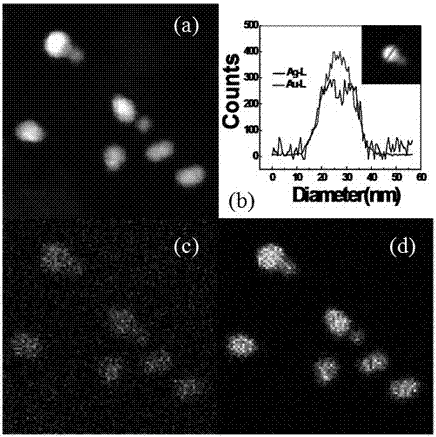

[0036] Take 20 mL of the Cinnamomum camphora leaf extract in a 50 mL Erlenmeyer flask, add 0.1 mL of 100 mmol / L silver nitrate solution to it, stir magnetically, react at 30°C for 24 h, then add 0.2 mL of 50 mmol / L chlorine Auric acid solution, magnetically stirred, and reacted for 4 hours at 30°C to obtain gold-silver bimetallic nanoparticles, such as figure 1 ;

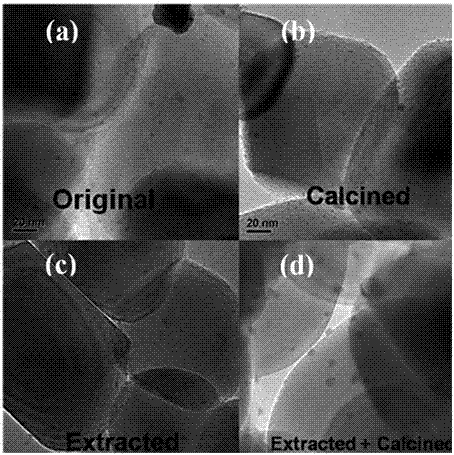

[0037] Add 0.5 g TiO to the gold-silver bimetallic nanosol 2 powder (anatase, 100nm), magnetically stirred for 2 h, filtered to get filter cake and dissolved in 20 mL deionized water, added 0.1 mL ionic liquid [BMIM][BF 4 ], magnetically stirred ...

Embodiment 2

[0039] Embodiment 2, the preparation method of the present embodiment is:

[0040] Get catalyst (d) 0.3 g obtained in example 1 and mix with 300 mL methylene blue solution, magnetically stir, every 2 min or 5min take a sample, scan on UV-Vis spectrophotometer, scan wavelength is 300-900 nm, degradation effect is as follows Figure 4 a, The degradation rate of methylene blue reaches 98% in 35 min.

Embodiment 3

[0041] Embodiment 3, the preparation method of the present embodiment is:

[0042] Get catalyst (d) 0.3 g obtained in Example 1 and mix with 300 mL rhodamine B solution, magnetically stir, take a sample every 2 min or 5 min, scan on the UV-Vis spectrophotometer, the scan wavelength is 300-900 nm, the degradation effect Such as Figure 4 b, The degradation rate of rhodamine B reaches 96% in 20 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com