Preparation and application of kapok fiber-based elastic foam material

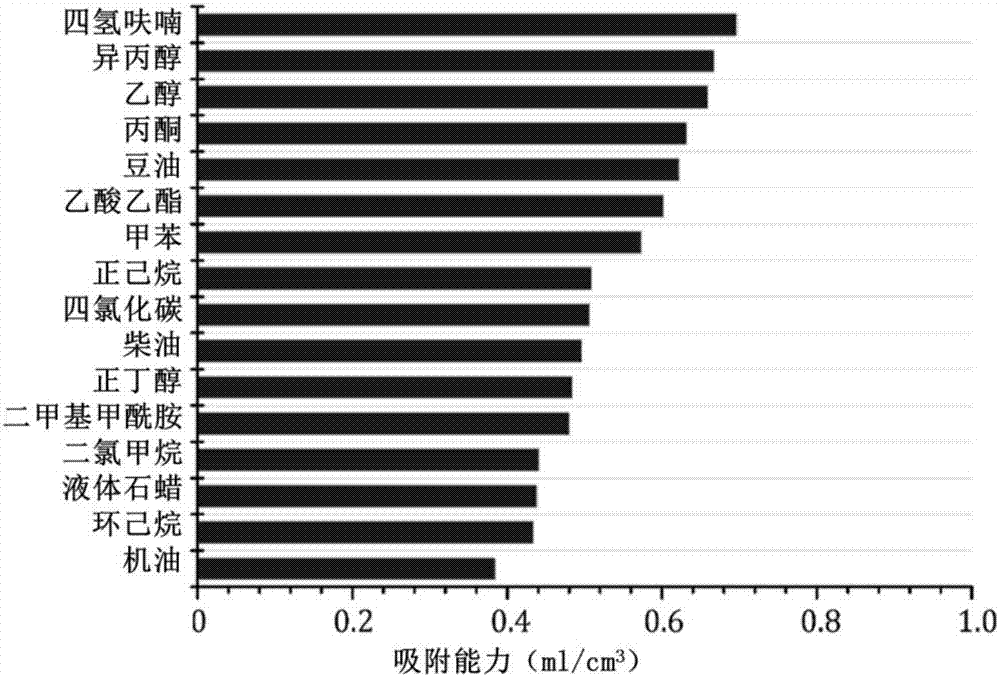

A kapok fiber and elastic foam technology, applied in the fields of alkali metal oxides/hydroxides, inorganic chemistry, alkali metal compounds, etc., can solve the problems of complex preparation process requirements, weak organic solvent adsorption capacity, and inability to reuse again , to achieve significant adsorption effect, low price, and excellent superhydrophobic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

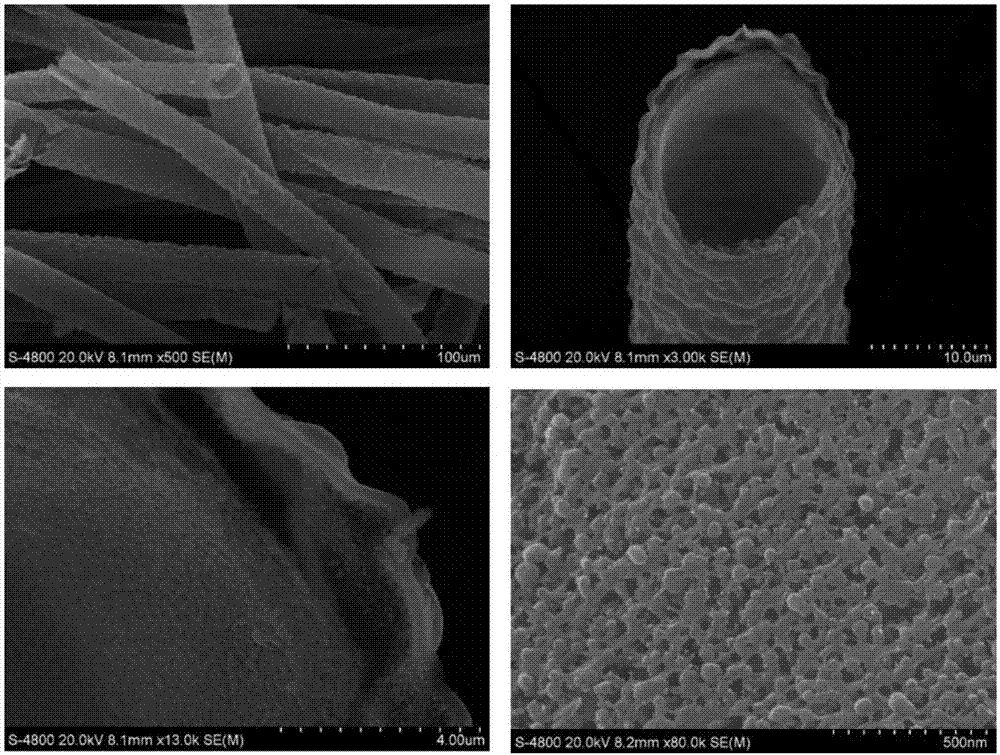

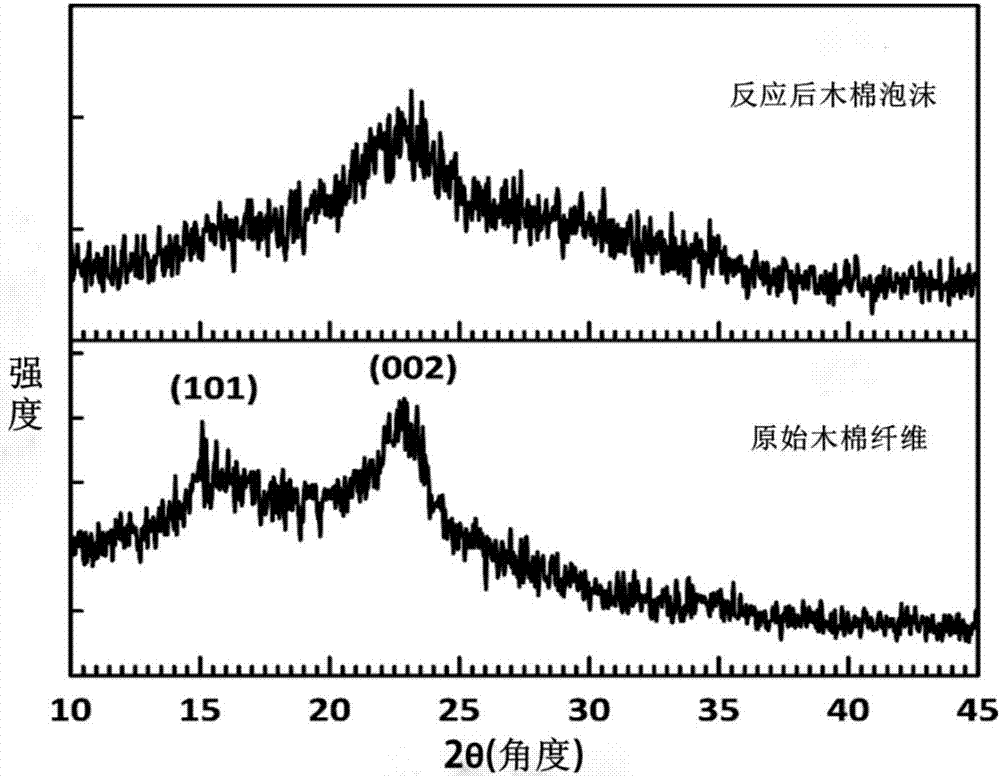

Embodiment 1

[0032] Weigh 0.8 g of kapok fiber and place it in a 25 ml polytetrafluoroethylene lined reactor, and add a 2.5% glutaraldehyde solution to soak for 12 hours. Then react at a constant temperature of 180°C for 24 hours, and the reaction product is first immersed in deionized water and then in absolute ethanol, rinsed, and dried naturally to obtain a cylindrical elastic foam with a diameter of 2 cm and a height of 2.5 cm.

Embodiment 2

[0034] This embodiment is different from Embodiment 1 in that the reaction temperature in the step is 220°C. Others are the same as in Example 1.

Embodiment 3

[0036] This embodiment is different from embodiment 1 in that the concentration of glutaraldehyde in the steps is 4%. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com