Palladium alloy catalyst, preparation method and applications thereof

A technology of catalyst and palladium alloy, which is applied in the field of palladium alloy catalyst and its preparation, can solve the problems of high cost and unsatisfactory electrocatalyst catalytic activity, and achieve the effects of reducing economic cost, high catalytic activity and stability, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

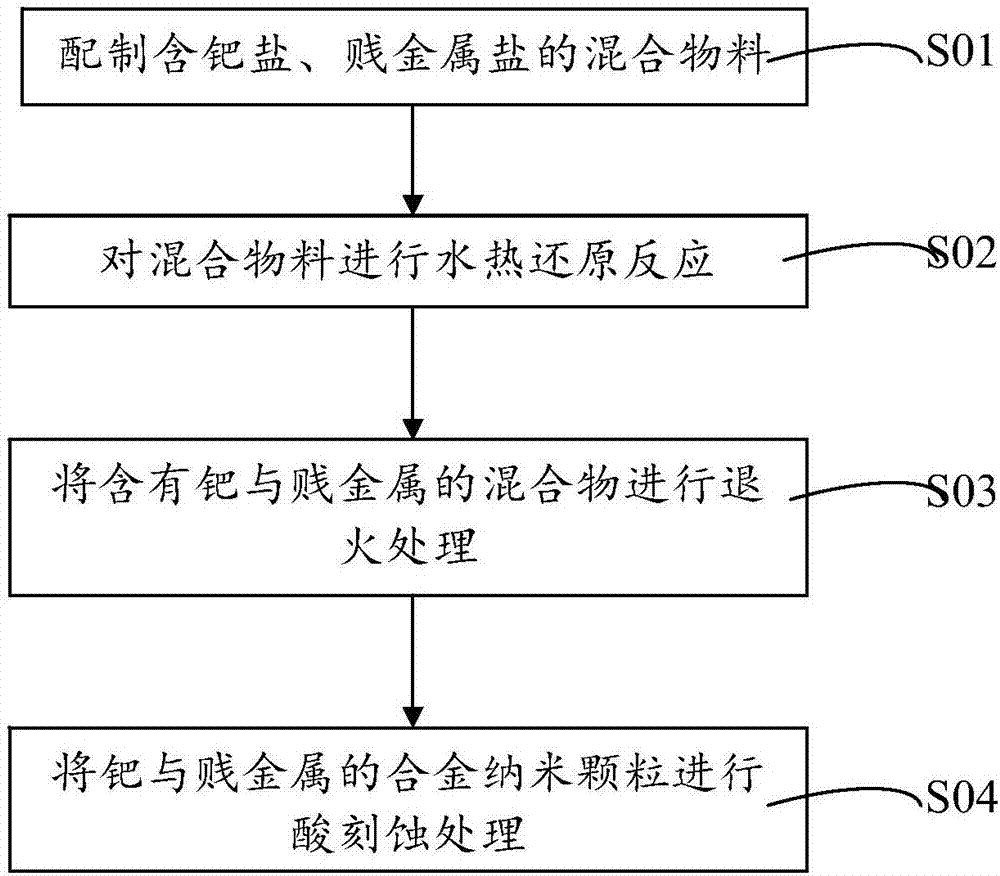

[0026] Correspondingly, the embodiment of the present invention also provides a method for preparing the above-mentioned palladium alloy catalyst. The process of the preparation method is as follows figure 1 shown, including the following steps:

[0027] S01. Preparation of mixed materials containing palladium salts and base metal salts: mixing palladium salts, base metal salts, reducing agents and stabilizers / surfactants to form mixed materials;

[0028] S02. Performing a hydrothermal reduction reaction on the mixed material: performing a solid-liquid separation after performing a hydrothermal reduction reaction on the mixed material to obtain a mixture containing palladium and a base metal;

[0029] S03. Annealing the mixture containing palladium and base metal: annealing the mixture of palladium and base metal in a protective atmosphere to obtain alloy nanoparticles of palladium and base metal;

[0030] S04. Performing acid etching treatment on the alloy nanoparticles of ...

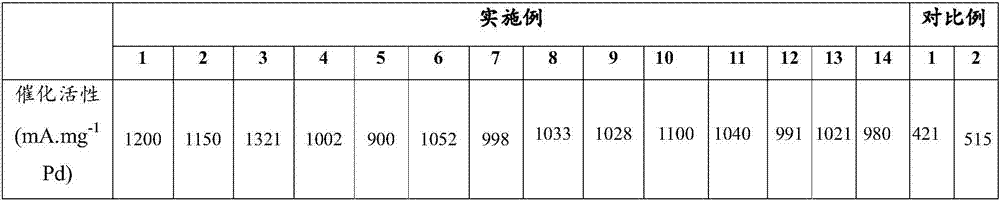

Embodiment 1

[0045] This embodiment provides a palladium alloy catalyst, the palladium alloy catalyst is alloy nanoparticles formed of palladium and copper elements, and the surface of the alloy nanoparticles has a porous structure.

[0046] Its preparation method is as follows:

[0047] S11: Weigh 0.03mmol of palladium chloride, 0.03mmol of copper acetylacetonate, 100mg of CTAB, 10ml of oleylamine and mix thoroughly by ultrasonication for half an hour;

[0048] S12: hydrothermally reacting at a temperature of 180° C. for 7 hours, and centrifuging and drying the product;

[0049] S13: Under the protection of argon, anneal at 250°C for 2 hours;

[0050] S14: Etching the product with acetic acid for 6 hours to obtain a porous PdCu alloy catalyst.

Embodiment 2

[0052] This embodiment provides a palladium alloy catalyst, the palladium alloy catalyst is alloy nanoparticles formed of palladium and copper elements, and the surface of the alloy nanoparticles has a porous structure.

[0053] Its preparation method is as follows:

[0054] S21: Weigh 0.03mmol of sodium chloropalladate, 0.03mmol of copper acetylacetonate, 100mg of PVP, and 10ml of oleylamine by ultrasonication for half an hour and mix well;

[0055] S22: heat water at a temperature of 180° C. for 12 hours, and centrifuge and dry the product;

[0056] S23: Annealing at 300°C for 2 hours under argon protection;

[0057] S24: Etching the product with acetic acid for 8 hours to obtain a porous PdCu alloy catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com