Modal testing method of large fan blades based on photogrammetry technology

A technology for fan blades and photogrammetry, which is used in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., and can solve the problem of high cost of a single scaled blade, inability to truly reflect the vibration state of the structure space, and inconvenient arrangement of camera LED light tubes, etc. problems, to achieve the effect of convenient operation, fast measurement speed and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

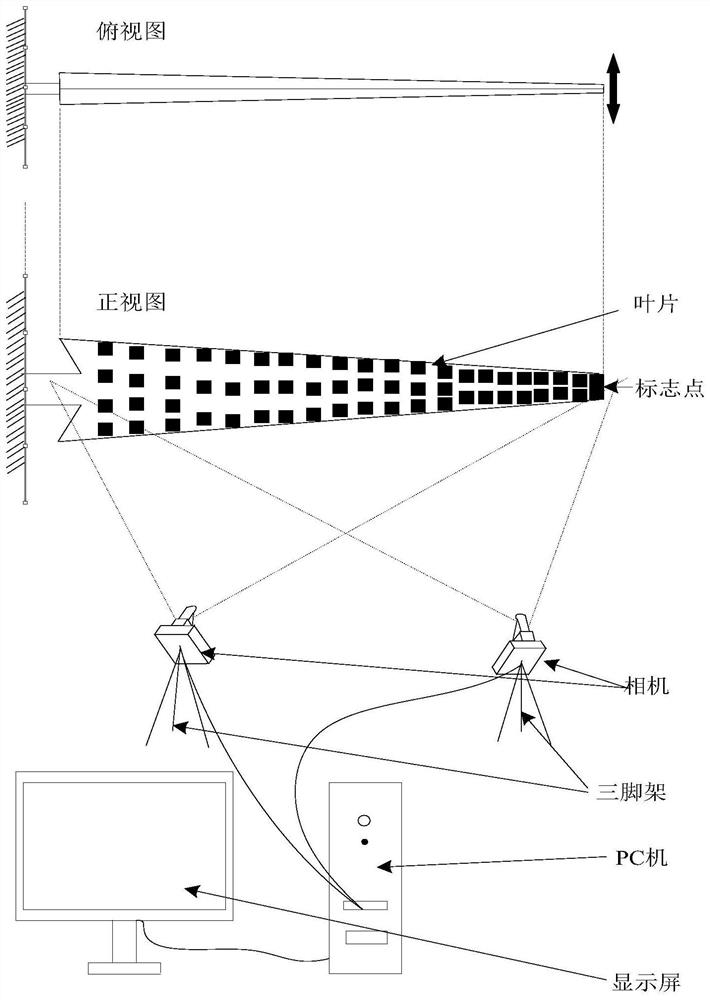

[0047]In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

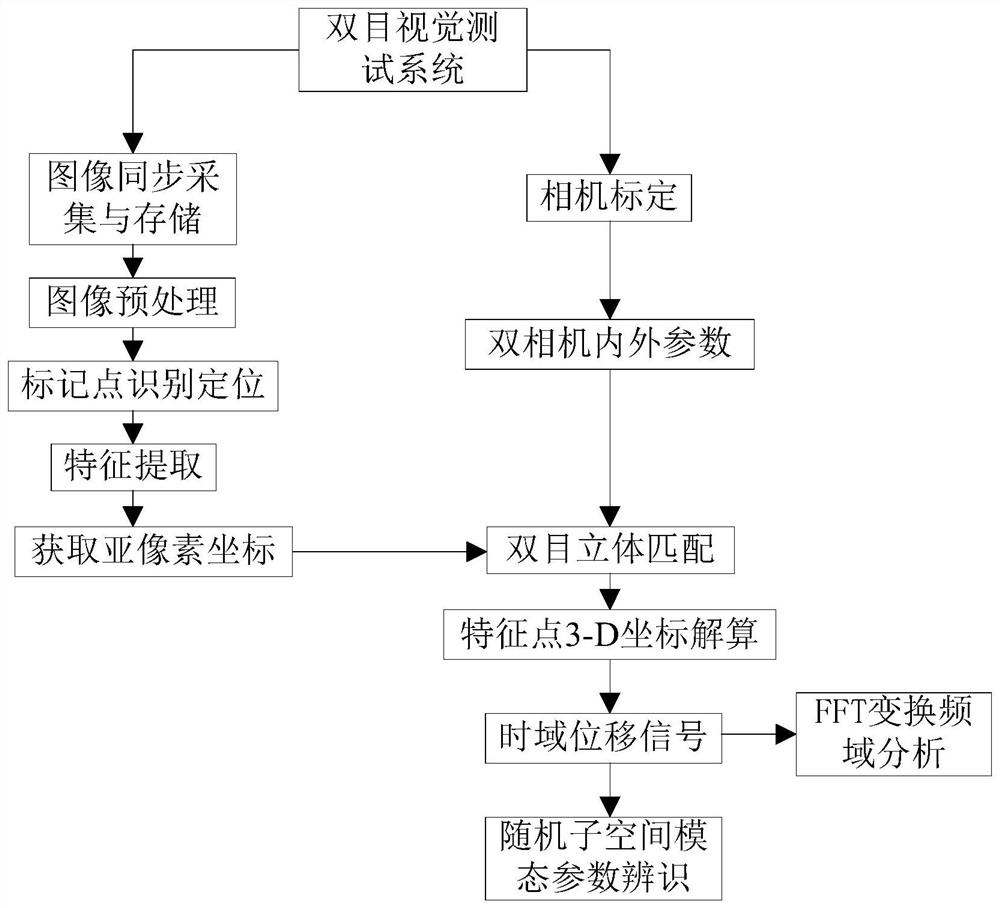

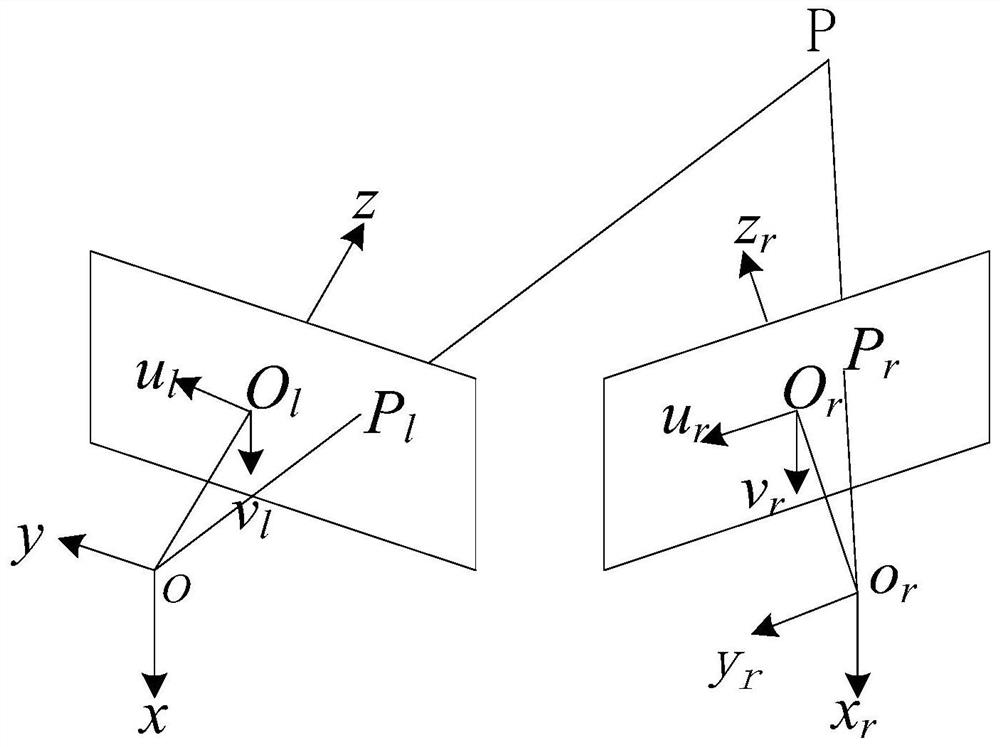

[0048] The core of the present invention is to provide a large-scale wind turbine blade modal test method based on photogrammetry technology, which adopts a pair of CMOS / CCD industrial cameras to synchronously shoot the surface image of the wind turbine blade under random excitation vibration, and identify and locate multiple The sub-pixel-level coordinates of the center of the marked point are extracted and the stereo matching of the two cameras is performed. The three-dimensional coordinates of each measuring point are calculated by three-dimensional reconstruction technology, and the displacement data is differentially processed to obtain the required vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com