An interior flow field measurement method for turbomachine

A measurement method, turbomachinery technology, applied in the direction of fluid velocity measurement, measuring device, velocity/acceleration/shock measurement, etc., can solve problems such as interference, inability to measure transient structure, difficulty in measuring internal flow field of multistage turbomachinery, etc. Achieve the effect of avoiding interference and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

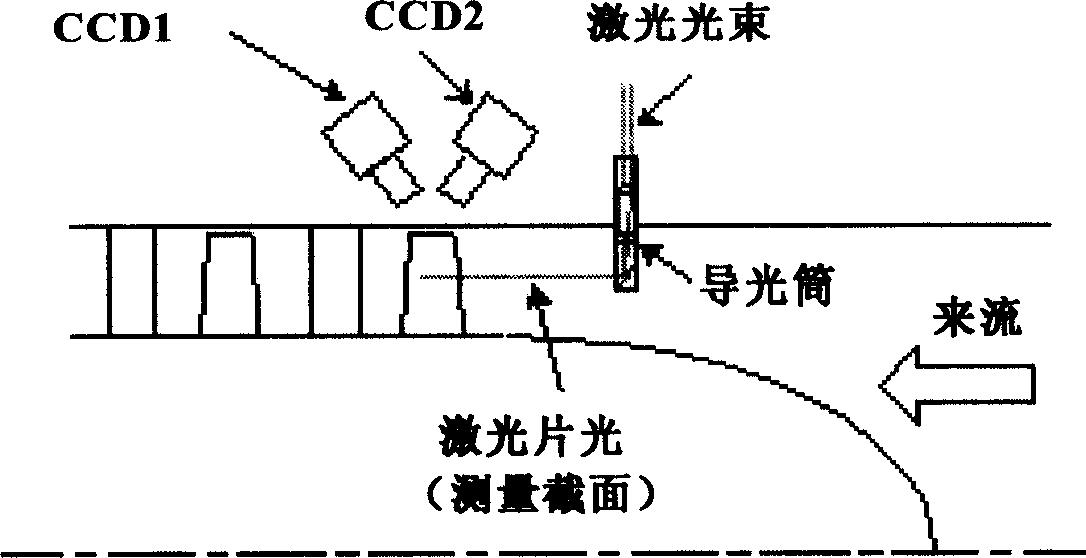

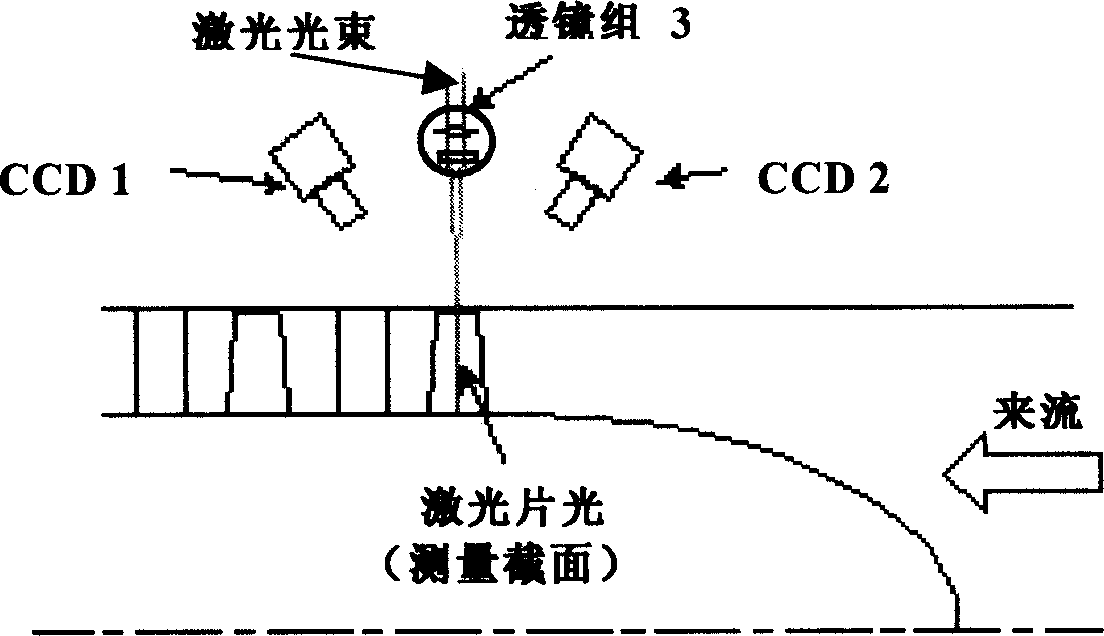

[0018] like figure 2 As shown, the implementation of the present invention does not need to change the SPIV system, only needs to follow figure 2 Lighting, re-arrangement of CCD camera 1, CCD camera 2 and lens group 3 forming laser sheet light in the manner shown is enough, but special calibration and three-dimensional velocity field synthesis should be carried out according to the characteristics of the turbine, and the measurement process and steps are the same as Regular measurements agree exactly.

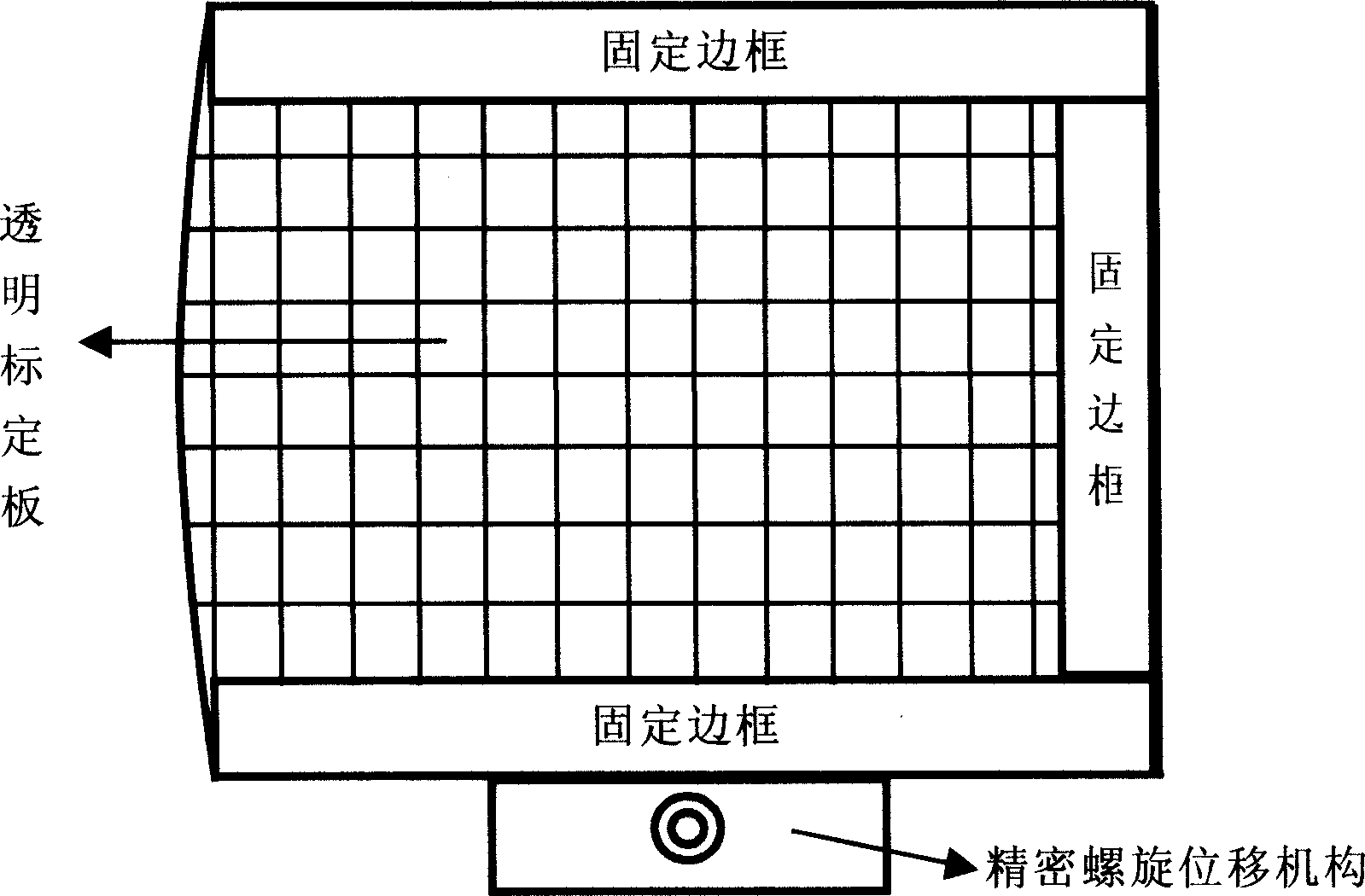

[0019] First, before measuring, it is necessary to use such as image 3 The transparent calibration object shown is used to calibrate the SPIV system. During the calibration process, the receiver window should also be worn, so the side of the transparent calibration object close to the receiver window should be made into an arc, which is consistent with the receiver window; in principle Calibration is required for each of the different measurement positions; the process and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com