Coiled tubing resistant to corrosion of small amount of CO2 and H2S and manufacturing method thereof

A coiled tube, a small amount of technology, applied in the coiled tube resistant to a small amount of CO2 and H2S corrosion and its manufacturing field, can solve the problems of stress corrosion, weight loss corrosion of sulfide, no significant effect on the corrosion resistance of pipes, etc., and achieve excellent corrosion resistance , Improve safety and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

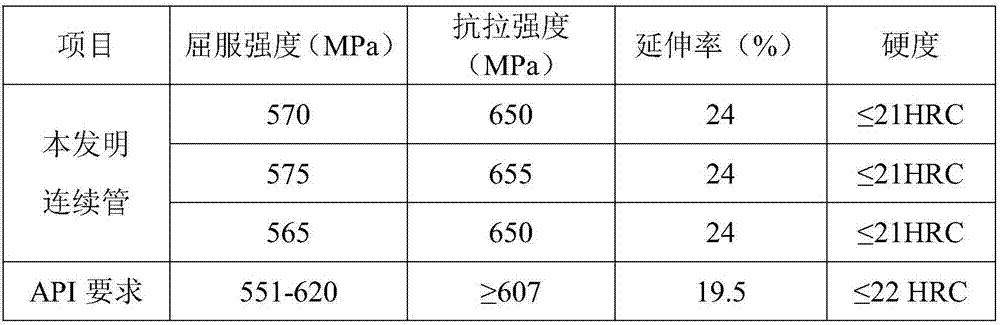

Examples

Embodiment Construction

[0033] The invention is resistant to a small amount of CO 2 and H 2 S corroded coiled tubing, the main manufacturing steps are as follows:

[0034] Step 1: Prepare coiled tubing

[0035] The mass percentage of the chemical composition of the coil is as follows: C: 0.04%; Si: 0.24%; Mn: 0.5%; P: 0.005%; S: 0.001%; Cu: 0.35%; Cr: 3.5%; : 0.3%; Ti: 0.015%; Al: 0.035%; Nb: 0.03%; Re: 0.015, the rest is Fe and unavoidable impurities.

[0036] Pre-desulfurization treatment of molten iron, smelting in converter with top-bottom combined blowing, LF heating desulfurization, VD vacuum decarburization, Ca treatment and other steps, so that the composition mass percentage of molten steel meets the above requirements, and then the steel can be tapped, and the continuous casting billet is cast into 100mm The thickness of the slab is reheated to 1200°C, and the roller mill is used to pass the thermomechanical control rolling process (TMPC). The rough rolling end temperature is controlle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com