Graphene polymer waterproofing coating mother material and preparation method thereof

A waterproof coating, graphene technology, applied in cement coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of graphene dispersion stability, compression of preparation costs, etc., achieve easy control of reaction conditions, and delay the corrosion rate. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

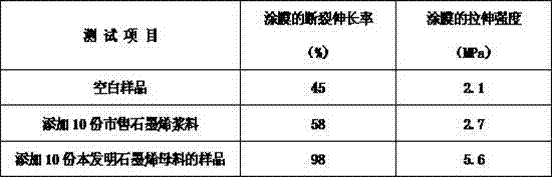

Examples

Embodiment 1

[0027] (1) Preparation of graphene / microporous materials

[0028] Put 20 parts by weight of graphene in deionized water for ultrasonic dispersion for 1 hour to obtain a uniformly dispersed graphene aqueous solution, pour 15 parts by weight of microporous material diatomaceous earth into the graphene aqueous solution, and mechanically stir at 60 ° C To slurry, spray drying to obtain graphene dispersed in the micropores of microporous materials to form graphene / microporous materials;

[0029] (2) Micro-crosslinking

[0030] Add the graphene / microporous material prepared by step (1) in the reaction kettle equipped with a thermometer, agitator and condenser, then add 15 parts by weight of polyacrylate emulsion with a solid content of 35%, and add it during stirring Initiators potassium persulfate and NaHCO 3 , react at room temperature for 1h, the polyacrylate emulsion is micro-crosslinked to form a film under the action of initiation, and the graphene / microporous material is co...

Embodiment 2

[0039] (1) Preparation of graphene / microporous materials

[0040] Place 30 parts by weight of graphene in deionized water and ultrasonically disperse to obtain a uniformly dispersed graphene aqueous solution, calcinate the zeolite powder at a high temperature, crush it to a powder below 20 microns, and pour 20 parts by weight of the microporous material zeolite powder into the In the graphene aqueous solution, stir mechanically at 100°C to a slurry state, spray dry to obtain graphene dispersed in the micropores of the microporous material to form graphene / microporous material;

[0041] (2) Micro-crosslinking

[0042] Add the graphene / microporous material prepared in step (1) into the reaction kettle equipped with a thermometer, a stirrer and a condenser, then add 30 parts by weight of polyacrylate emulsion with a solid content of 30%, and add the initiator during stirring. Ammonium persulfate and NaHCO 3 , react at room temperature for 2 hours, the polyacrylate emulsion is m...

Embodiment 3

[0051] (1) Preparation of graphene / microporous materials

[0052] After 25 parts by weight of graphene was placed in deionized water for ultrasonic dispersion for 3 hours, a uniformly dispersed graphene aqueous solution was obtained, and 15 parts by weight of microporous material silica airgel was poured into the graphene aqueous solution, at 60 ° C Under mechanical stirring to a slurry state, spray drying to obtain graphene dispersed in the micropores of the microporous material to form graphene / microporous material;

[0053] (2) Micro-crosslinking

[0054] Add the graphene / microporous material prepared by step (1) into the reaction kettle equipped with a thermometer, a stirrer and a condenser, then add 20 parts by weight of polyacrylate emulsion with a solid content of 30%, and add it during stirring Initiators potassium persulfate and NaHCO 3 , react at room temperature for 1h, the polyacrylate emulsion is micro-crosslinked to form a film under the action of initiation, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com