Industrial circulating water processing and production device and production method using the same

A technology for industrial circulating water and production equipment, which is applied in chemical instruments and methods, water/sewage treatment, biological water/sewage treatment, etc. problems, to achieve rapid and efficient purification, reduce production costs, and short sterilization time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

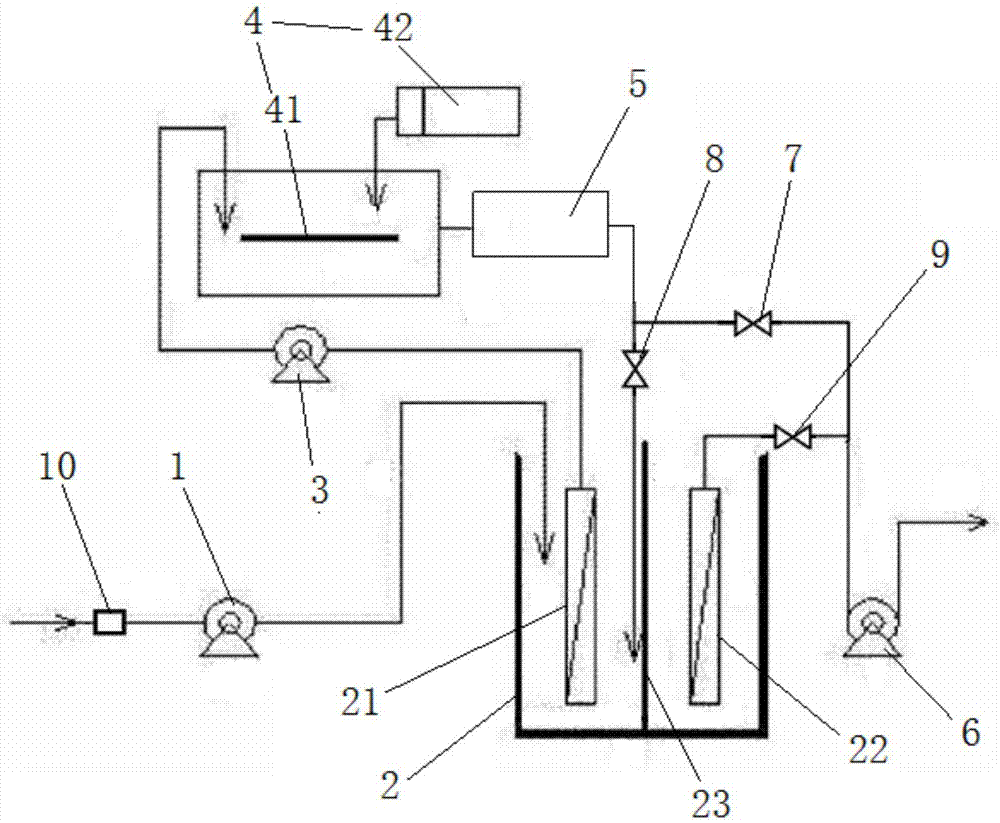

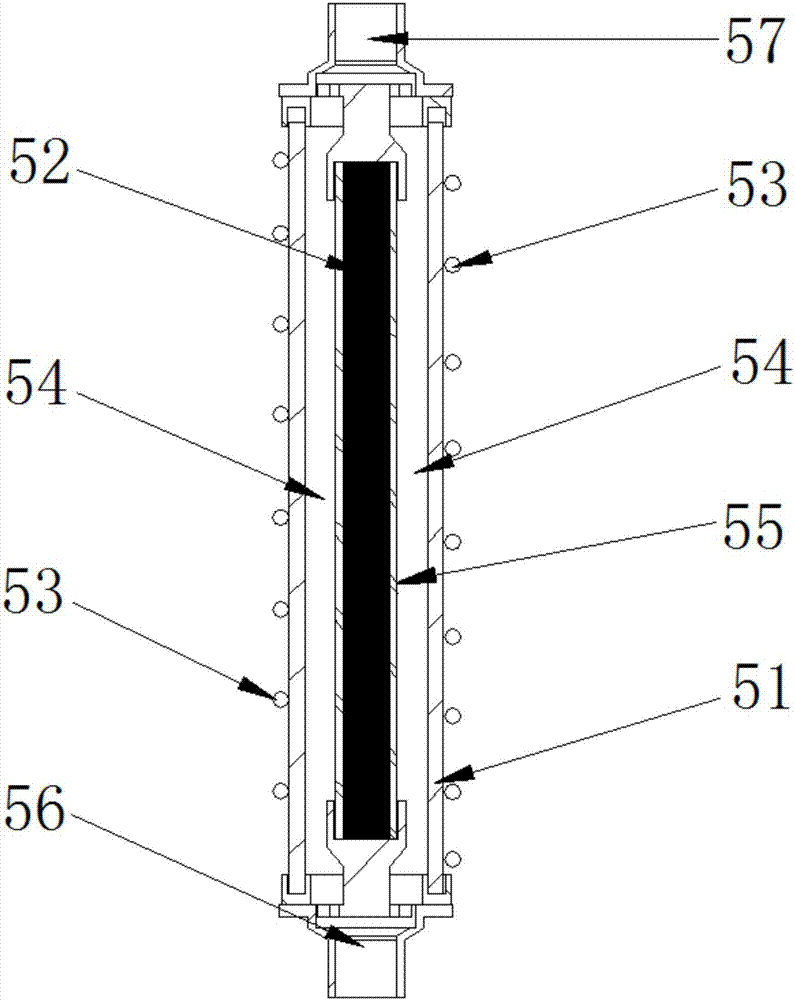

[0023] like figure 1 and figure 2 As shown, a kind of industrial circulating water processing production device provided by the present invention includes water inlet pump 1, first reactor 2, circulation pump 3, second reactor 4, third reactor 5 and water outlet pump 6, so The water inlet pump 1 is used to introduce sewage into the first reactor 2; the first reactor 2 is a membrane bioreactor, including a first membrane module 21 and a second membrane module 22 arranged therein, the The water outlet end of the first membrane module 21 is connected with the second reactor 4 through the circulating pump 3, and the circulating pump 3 is used to pump the water in the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com