A kind of preparation method of flexible highly conductive graphene film

A graphene film, high conductivity technology, applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of low material conductivity, complicated preparation process, low density, etc., achieve good flexibility, simple process, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

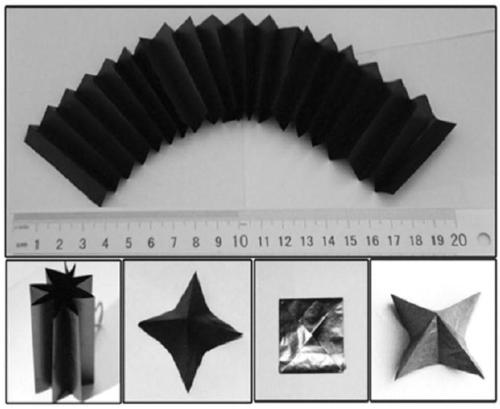

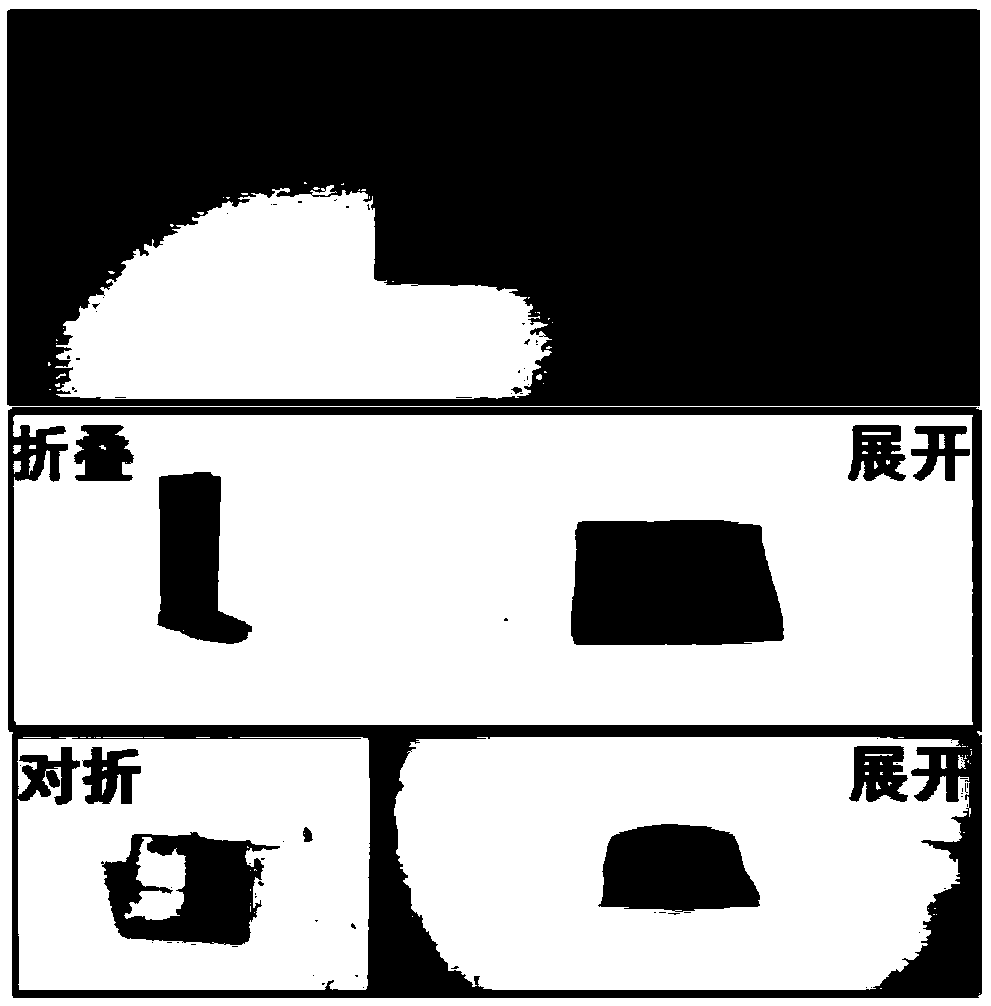

Image

Examples

specific Embodiment approach 1

[0028] Specific embodiment 1: This embodiment provides a method for preparing a highly conductive flexible composite material by using graphene sponge and polydimethylsiloxane to compound the following steps:

[0029] 1. Preparation of Graphene Oxide: Add 40g of natural flake graphite to the mixed acid and stir under the conditions of 500r / min and 40min. After that, add potassium permanganate in 7 times at 20 min intervals (time interval is 20 min), adjust the stirring temperature and speed to 35℃, 500r / min, and place it in a water bath for constant temperature stirring for 5 hours, then add the stirring mixture To ice water, and add 30% hydrogen peroxide to the ice water to obtain a suspension, and finally filter, centrifuge and wash to obtain graphene oxide. Add 24mg graphene oxide per milliliter to the ratio and deionized water to obtain dispersion liquid.

[0030] The mass ratio of potassium permanganate to the volume of mixed acid is 6g:1L; the mass ratio of natural flake gra...

specific Embodiment approach 2

[0040] Embodiment 2: The method for preparing a flexible and highly conductive graphene film in this embodiment is carried out according to the following steps:

[0041] 1. Preparation of Graphene Oxide: Add 20g of natural flake graphite to sulfuric acid and phosphoric acid to prepare a mixture, stir under the conditions of 500r / min, 40min. Then add potassium permanganate in 7 times at 20 min intervals, adjust the stirring temperature and speed to 35℃, 500r / min, and place it in a water bath for 5h at constant temperature, then add the stirring mixture to ice water and add it to 30% hydrogen peroxide was added to the ice water to obtain a graphene suspension. Finally, the graphene oxide suspension was filtered, centrifuged and washed to obtain graphene oxide, which was diluted to 12 mg / ml with deionized water.

[0042] The mass ratio of potassium permanganate to the volume of mixed acid is 6g:1L; the mass ratio of natural flake graphite to the volume of hydrogen peroxide is 1g:2mL; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com