A molding tool for foam sandwich composite structure winglet

A composite material and molding tooling technology, which is applied in the field of molding tooling of foam sandwich composite structure winglets, can solve the problems of difficult control of internal quality and surface quality, complex profile, large regional curvature, etc. Quality and surface quality, reducing mold weight, ensuring the effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

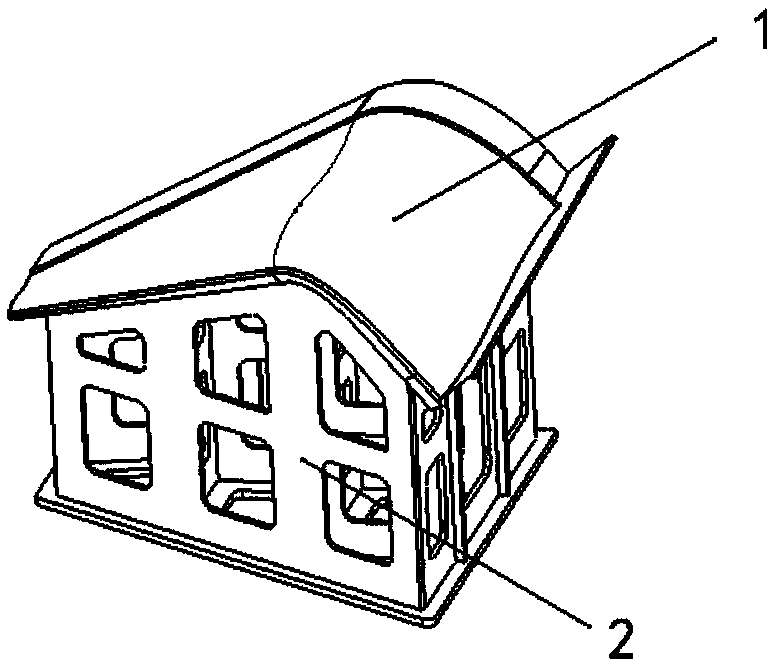

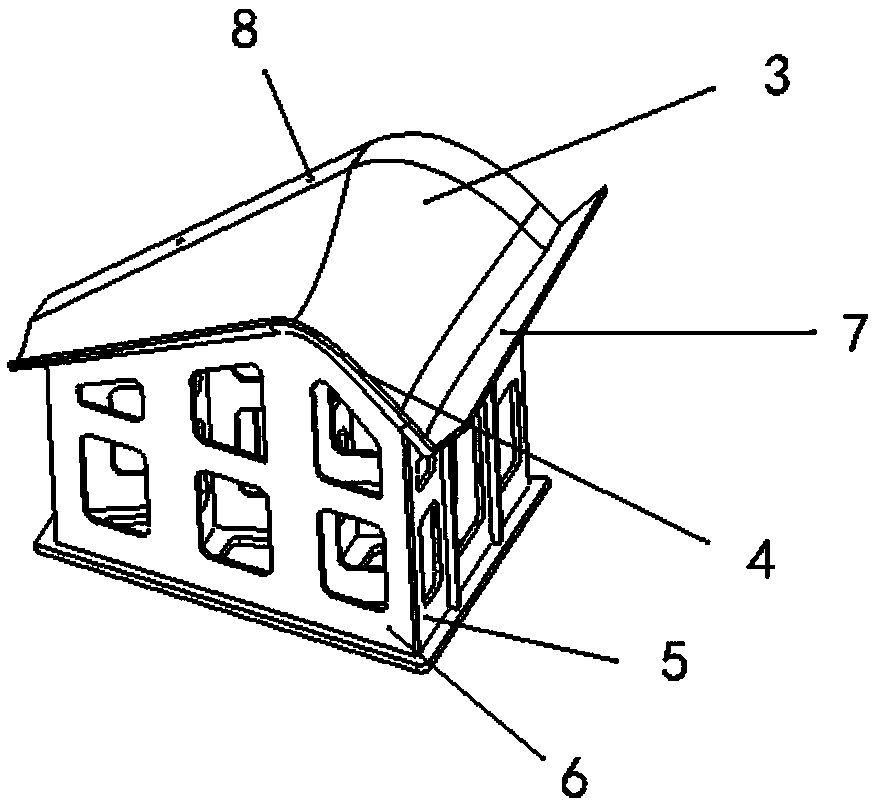

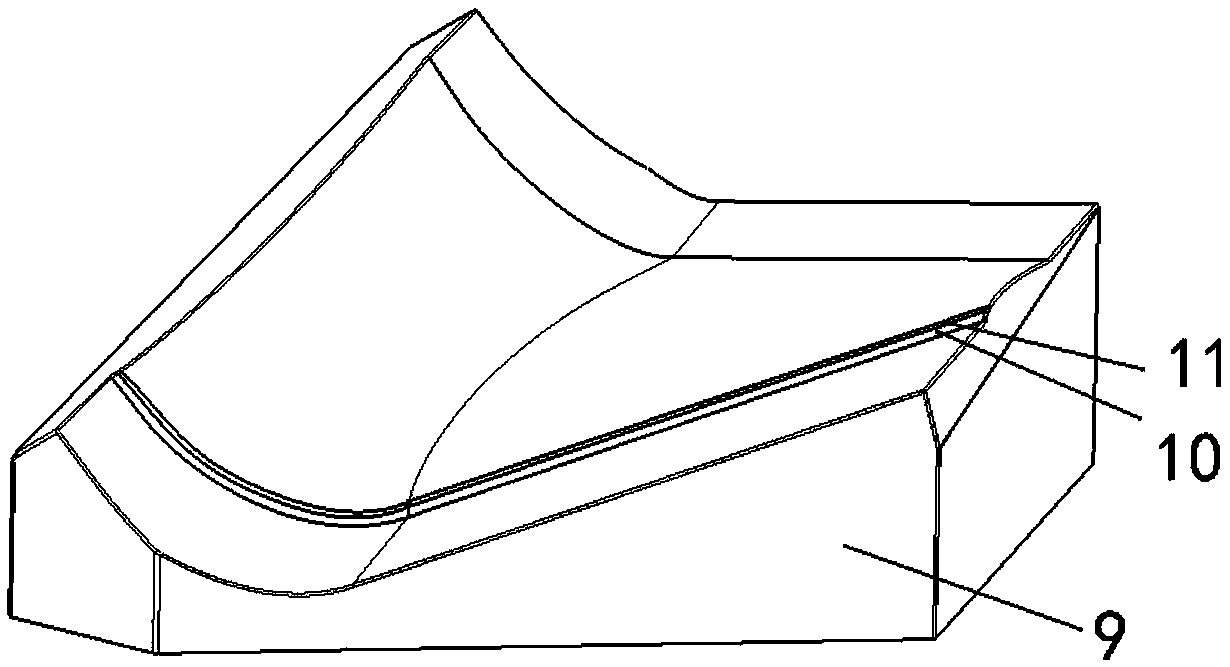

[0018] The forming tooling used for the foam sandwich composite structure winglet is composed of an upper forming die 1 and a lower forming die 2, the upper forming die 1 is a resin-based composite material mold, and the lower surface of the mold is connected with the foam sandwich composite material structural winglet. The profiles on the tiplets are the same. The upper forming die 1 carries out lay-up molding on the upper forming die stacking die 13 . The lower forming die 2 is a composite material frame die, which is composed of a longitudinal partition 5, a transverse partition 6, a bottom plate of the lower forming die frame 12 and a forming panel 3 of the lower forming die. During the manufacturing process of the lower forming die 2, the 8mm thick glass The fiber board is processed by numerical control, and the lower forming mold transverse partition 5, the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com