Vitex negundo treatment method for weaving

A treatment method and technology for vitex, applied in the direction of wood treatment, wood treatment details, reed/straw treatment, etc., can solve the problems of poor flexibility of vitex, poor paint performance, not as good as wicker, etc. Lacquer properties, easy to remove skin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

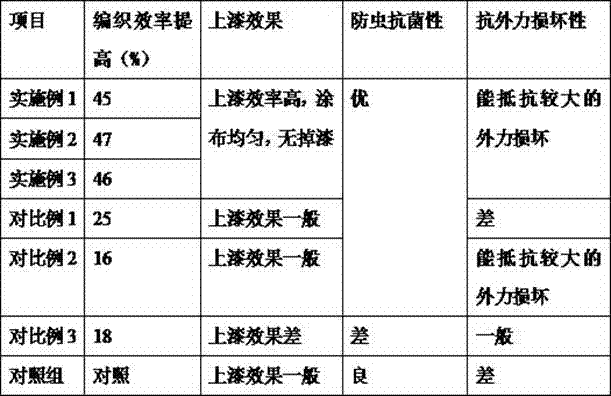

Examples

Embodiment 1

[0015] A method for treating wattles for weaving, comprising the following steps:

[0016] (1) The harvested Vitex is sun-dried for 3 days. During this period, the Vitex is evenly irradiated by turning over the sun. After the sun-dried Vitex is removed, the bifurcation is removed with a knife, the main stem is kept, and the rough joints are scraped flat. Thickness and length are classified into categories;

[0017] (2) Put the preliminarily treated Vitex on steam at 280°C for 10 minutes, take out the softened Vitex, peel off the outer skin with a knife, and tie heavy objects on both ends of the Vitex. Put it on the rack and keep it balanced. After 2 days, change the bending direction of the Vitex once, continue to bear the weight for 2 days, remove the heavy object, and the Vitex keeps bending naturally;

[0018] (3) Soak the naturally curved vitex in the prepared soaking solution for 7 hours. The soaking solution is composed of the following raw materials in terms of mass pe...

Embodiment 2

[0023] A method for treating wattles for weaving, comprising the following steps:

[0024] (1) The harvested Vitex is sun-dried for 4 days. During this period, the Vitex is evenly irradiated. Use a knife to remove the bifurcation of the sun-dried Vitex, keep the main stem, and smooth the rough joints. Thickness and length are classified into categories;

[0025] (2) Put the preliminarily treated Vitex on steam at 290°C for 12 minutes, take out the softened Vitex, peel off the outer skin with a knife, and tie heavy objects on both ends of the Vitex. Keep the balance on the rack. After 3 days, change the bending direction of the Vitex once, continue to bear the weight for 3 days, remove the heavy object, and the Vitex keeps bending naturally;

[0026] (3) Soak the naturally curved vitex in the prepared soaking solution for 8 hours. The soaking solution is composed of the following raw materials in terms of mass percentage: 2.5% neoprene latex, 1.4% sodium silicate, and 1.2% sod...

Embodiment 3

[0031] A method for treating wattles for weaving, comprising the following steps:

[0032] (1) The harvested Vitex is sun-dried for 5 days. During this period, the Vitex is evenly irradiated. Use a knife to remove the bifurcation of the sun-dried Vitex, keep the main stem, and scrape the rough joints. Thickness and length are classified into categories;

[0033] (2) Put the preliminarily treated Vitex on steam at 300°C for 15 minutes, take out the softened Vitex, peel off the outer skin with a knife, and tie heavy objects on both ends of the Vitex. Keep the balance on the shelf, and after 4 days, change the bending direction of the Vitex once, and continue to bear the weight for 4 days, remove the heavy object, and the Vitex keeps bending naturally;

[0034] (3) Soak the naturally curved vitex in the prepared soaking solution for 10 hours. The soaking solution is composed of the following raw materials in terms of mass percentage: 2.6% neoprene latex, 1.5% sodium silicate, 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com